Automatic typesetting equipment for art design

A technology of art and equipment, applied in the field of automatic typesetting equipment for art design, which can solve the problems of invalid typesetting paper and inability to adjust typesetting paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

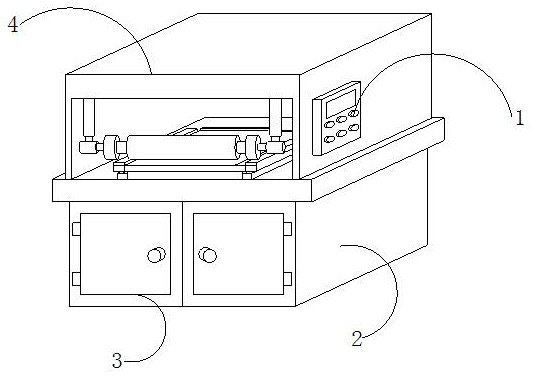

[0027] see Figure 1-Figure 5 , an automatic typesetting device for art design, its structure includes a control box 1, a storage box 2, a closing door 3, and an operation box 4, the control box 1 is installed on the operation box 4, and the operation box 4 and the control box 1, a storage box 2 is installed on the operation box 4, the storage box 2 is fixedly connected with the operation box 4, a closing door 3 is installed on the storage box 2, and the closing door 3 is connected to the storage box Box 2 clearance fit;

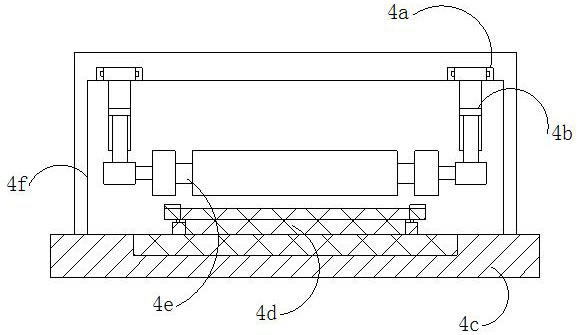

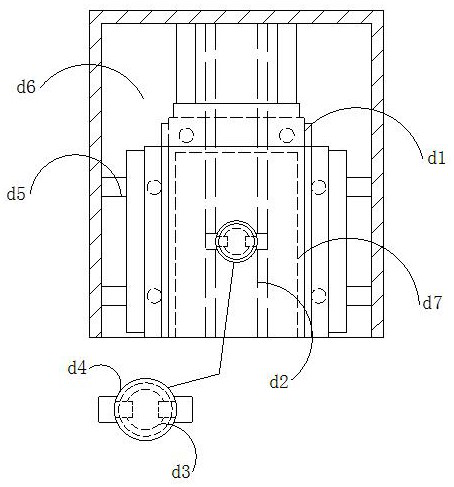

[0028]Described operating box 4 is provided with moving groove 4a, telescopic rod 4b, base plate 4c, manipulator 4d, replacer 4e, support frame 4f, and described moving groove 4a is installed on the supporting frame 4f, and described supporting frame 4f and moving groove 4a are connected, the moving groove 4a is provided with a telescopic rod 4b, the telescopic rod 4b is slidingly connected with the moving groove 4a, the support frame 4f is installed on the...

Embodiment 2

[0037] see Figure 1-Figure 6 , an automatic typesetting device for art design, its structure includes a control box 1, a storage box 2, a closing door 3, and an operation box 4, the control box 1 is installed on the operation box 4, and the operation box 4 and the control box 1, a storage box 2 is installed on the operation box 4, the storage box 2 is fixedly connected with the operation box 4, a closing door 3 is installed on the storage box 2, and the closing door 3 is connected to the storage box Box 2 clearance fit;

[0038] Described operating box 4 is provided with moving groove 4a, telescopic rod 4b, base plate 4c, manipulator 4d, replacer 4e, support frame 4f, and described moving groove 4a is installed on the supporting frame 4f, and described supporting frame 4f and moving groove 4a are connected, the moving groove 4a is provided with a telescopic rod 4b, the telescopic rod 4b is slidingly connected with the moving groove 4a, the support frame 4f is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com