Automatic sampling structure for pipe production

An automatic sampling and pipe technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of large inspection workload, low sampling efficiency, low sampling efficiency, etc., to reduce workload, facilitate packaging, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

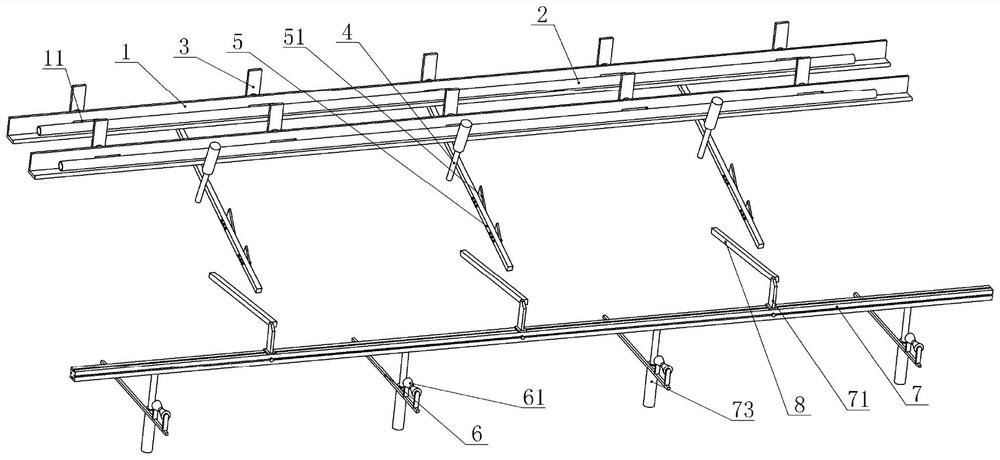

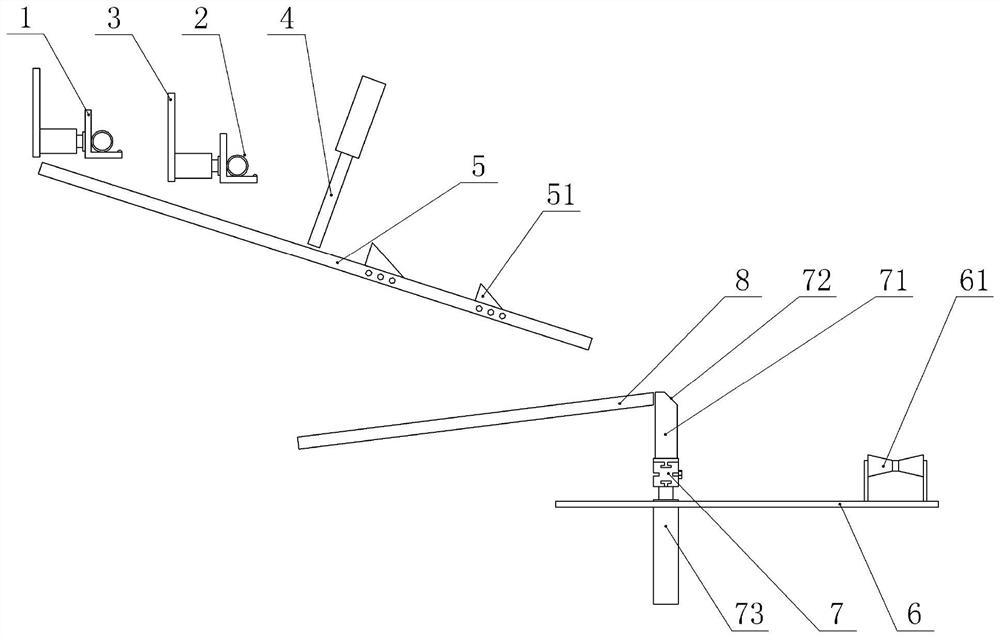

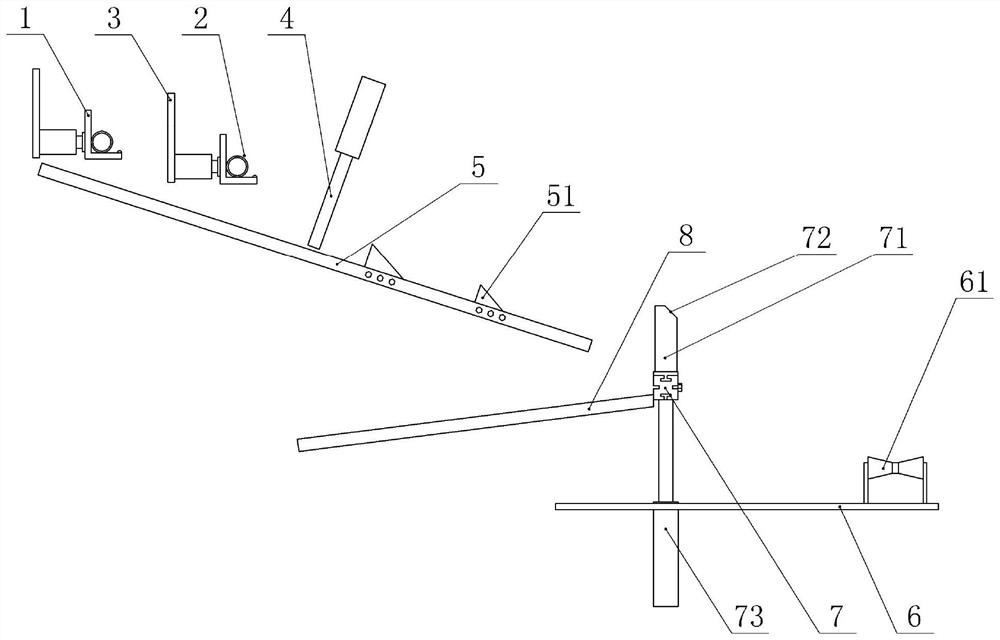

[0029] Automatic sampling structures for pipe production, such as figure 1 As shown, it includes a frame (not shown in the figure), a guide unit and a sampling unit, and the guide unit includes a first guide member 5, an upper push plate, an upper push member, a limit rod 4, a limit member, a first L-shaped Plate, the second L-shaped plate 1 and two baffle plates 51, the first L-shaped plate and the second L-shaped plate 1 are all installed on the frame by bolts, and the second L-shaped plate 1 is located behind the first L-shaped plate side, such as figure 2 As shown, the longitudinal section of the first L-shaped plate and the second L-shaped plate 1 is L-shaped, and the right ends of the first L-shaped plate and the second L-shaped plate 1 are integrally formed with protrusions to prevent the pipeline from moving from the first L-shaped plate. plate and the second L-shaped plate 1 falls.

[0030] Another example figure 1 As shown, the vertical parts of the first L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com