An automatic filling and unloading device for a hydrogen refueling station

A hydrogen refueling station and gas device technology, applied in the installation device of container structure, container filling method, fixed capacity gas storage tank, etc., can solve the problem of inability to fill, inconvenient operation and maintenance, and inability to realize filling and unloading And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described below with reference to the accompanying drawings.

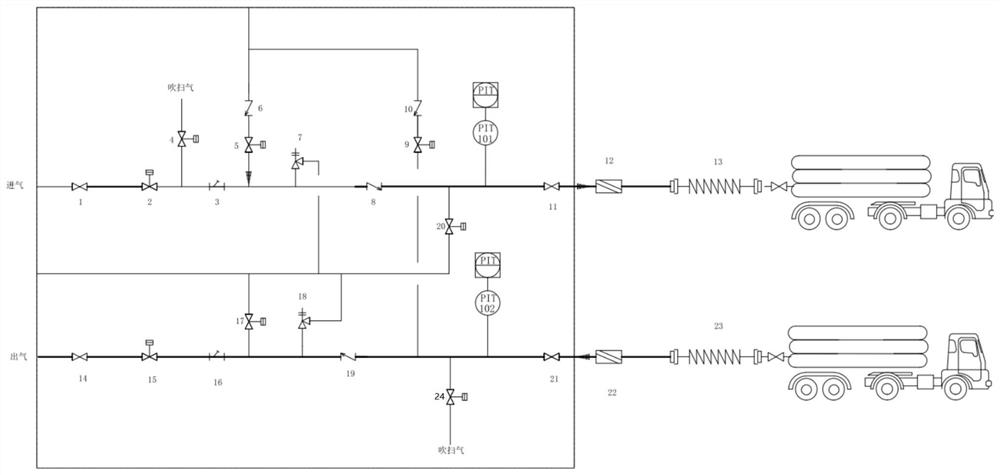

[0036] Please refer to figure 1 , the present invention provides an automatic filling and unloading device for a hydrogen refueling station, the system comprising:

[0037] air inlet and outlet;

[0038] The air inlet passes through the first hand valve 1, the first automatic shut-off valve 2, the first filter 3, the first check valve 8, the second hand valve 11, the first break valve 12, the filling hose 13 and the Long tube trailer connection;

[0039] The air outlet passes through the third hand valve 14, the second automatic shut-off valve 15, the second filter 16, the second check valve 19, the fourth hand valve 21, the second break valve 22, the unloading hose 23 and the long valve in sequence. Tube trailer connection.

[0040] A third automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com