Intensive storage warehouse for stacking machine combined with shuttle vehicle

A technology of stacker and shuttle, which is applied in the field of dense storage and storage, can solve the problems of inconsistent volume and size, inconvenient picking up, and intensive storage of goods, so as to improve the management level of goods, improve storage efficiency, and improve management efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

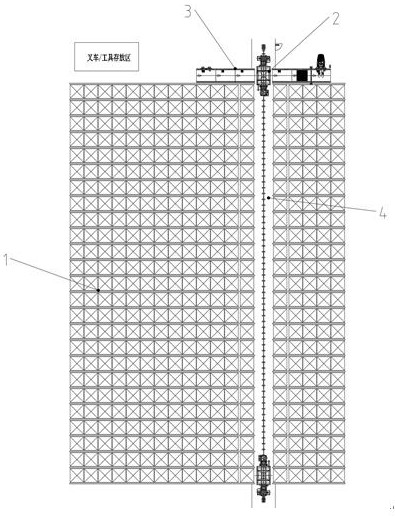

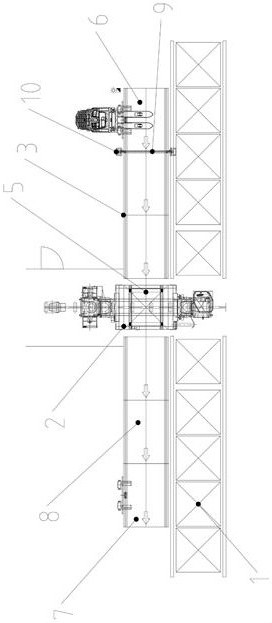

[0018] A dense storage vertical warehouse for stackers combined with shuttle vehicles. The vertical storage system includes shelves 1, stackers 2, shuttle vehicles, in / out delivery conveyor lines 3 and warehouse management software, and shelves 1 are set on the storage site , the shelf 1 is set as a dense discharge space structure, the shelf 1 is extended in the three-dimensional direction, and a roadway 4 is opened in the middle of the shelf 1, and a stacker 2 is arranged in the roadway 4, and the stacker 2 runs on the track and Working in the laneway 4, the shelf 1 is divided into at least two storage areas by the laneway 4, and the two storage areas are respectively a long-distance storage area and a short-distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com