Assembling framework for temporary positioning of cast-in-place stand column reinforcement cage and construction method

A technology of reinforcement cages and pile foundation reinforcement cages, which is applied in the direction of erecting/assembling bridges, bridge materials, bridges, etc., can solve problems such as ensuring construction quality and saving construction costs, high risk factor, and long construction time, so as to improve overall stability Sexuality, efficient construction efficiency, and the effect of saving on-site costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

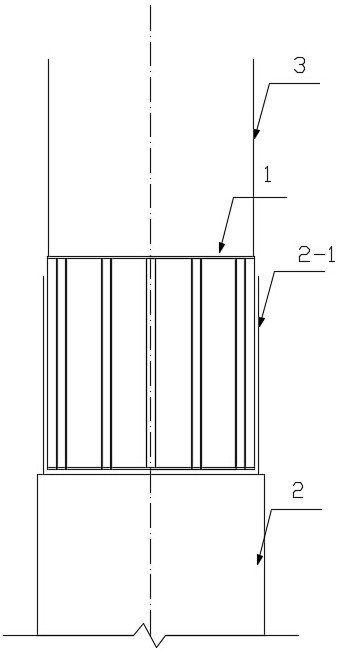

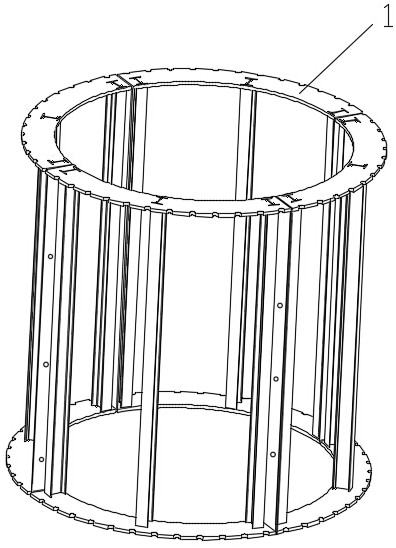

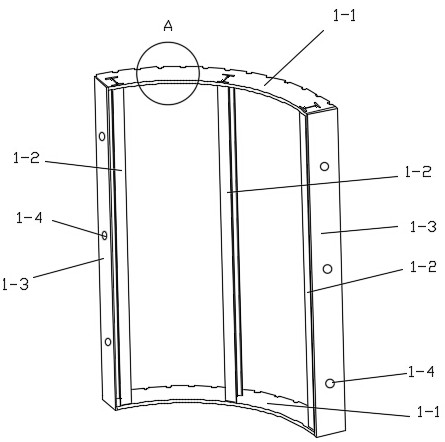

[0035] Such as Figure 1-4 As shown, an assembled skeleton for temporary positioning of cast-in-place column reinforcement cages includes several positioning members 1 connected in sequence, and several positioning members 1 are connected in sequence to form a ring structure; -2 and two positioning pieces 1-1 connected to the upper and lower ends of the I-beam 1-2, the two positioning pieces 1-1 are arranged in parallel; the positioning piece 1-1 is a fan-shaped structure, and the outside of the positioning piece 1-1 Equidistantly arranged matching holes 1-5 are formed on the ring; steel plates 1-3 are provided at both ends of the positioning piece 1-1, and the upper and lower ends of the steel plate 1-3 are connected to the ends of the two positioning pieces 1-1 , and the steel plates 1-3 are formed with threaded holes 1-4; the adjacent positioning m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com