A comprehensive quantitative detection and repair process for cracks on the surface of underground structures

A technology for underground structures and surface cracks, used in building maintenance, measuring devices, building structures, etc., can solve problems such as the overall health of difficult underground structures, and it is difficult to guide the scientific repair and management of different types of cracks. Experience evaluation, comprehensive evaluation process, and the effect of avoiding unnecessary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

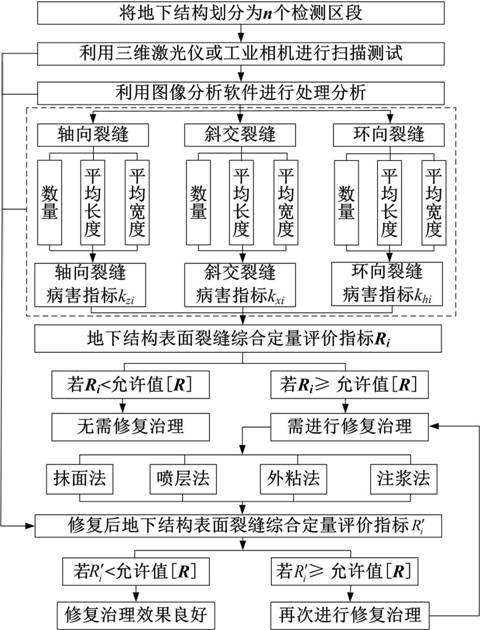

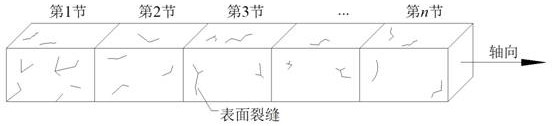

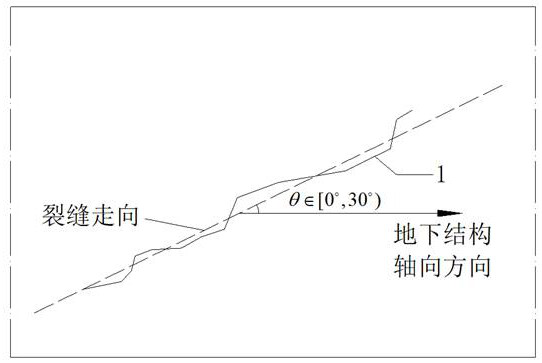

[0042] In a typical embodiment of the present invention, as Figure 1-Figure 9 As shown, a comprehensive quantitative detection and repair process for surface cracks in underground structures is proposed. For ease of understanding, this embodiment takes a long and narrow underground structure as an example. The underground structure includes a total of n The two adjacent sections are deformation joints. The quantitative detection and repair process includes the following steps:

[0043] Step 1: After the construction of the underground structure is completed, divide the underground structure into n detection section ( n is a positive integer);

[0044] In step 1, when the detection section of the underground structure is divided in this embodiment, the basis for the division is the deformation joint of the underground structure, and the corresponding detection section is n indivual.

[0045] It can be understood that, in other embodiments, the division can also be made acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com