Wet running plate clutch and motor vehicle transmission

A technology for motor vehicles and clutches, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., to solve problems such as occupancy and lubricating oil accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

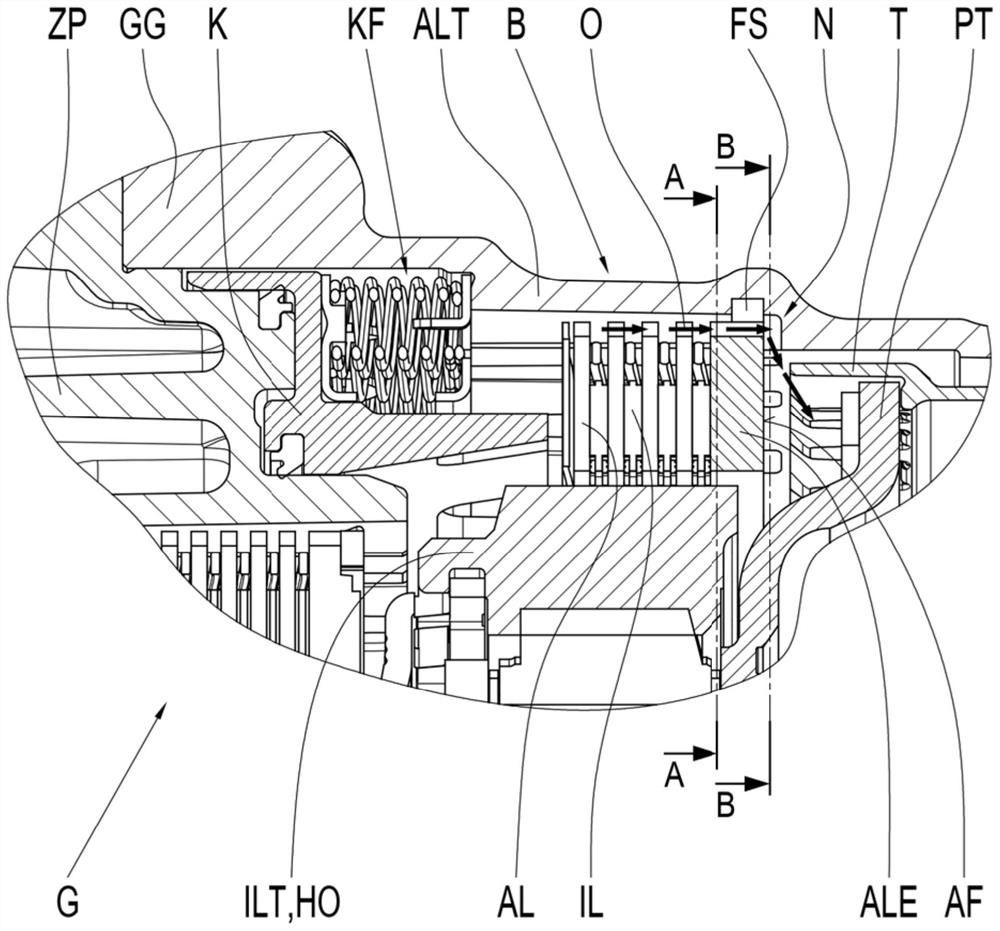

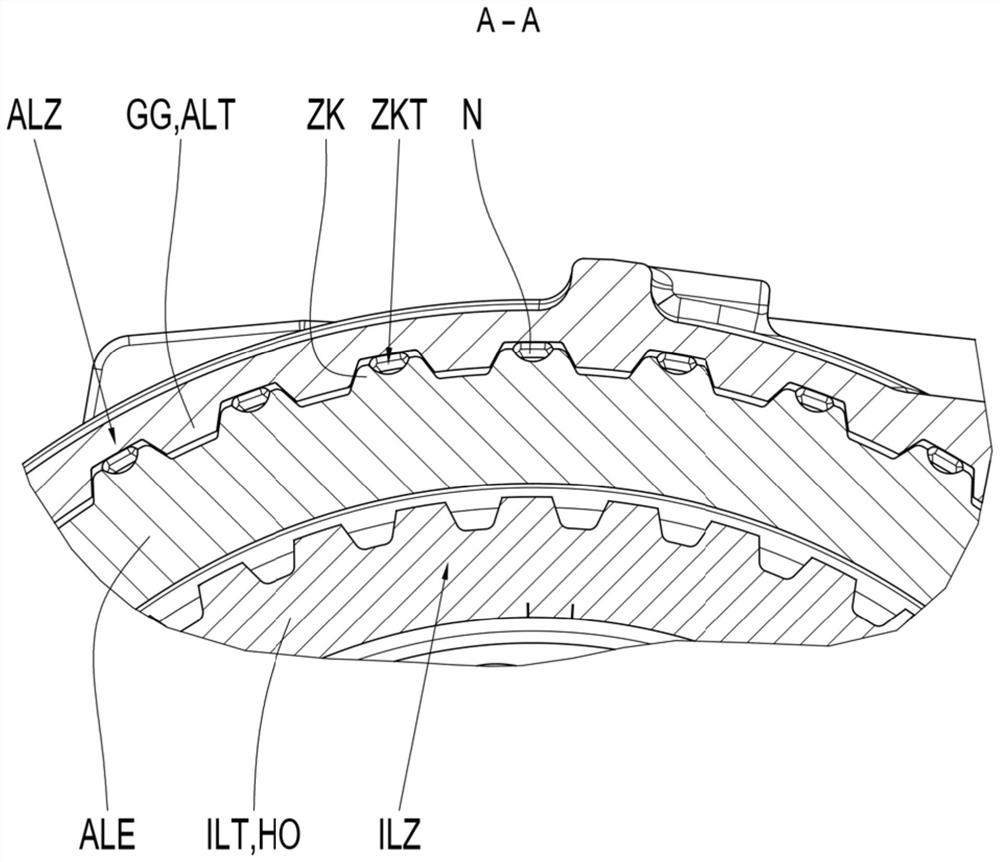

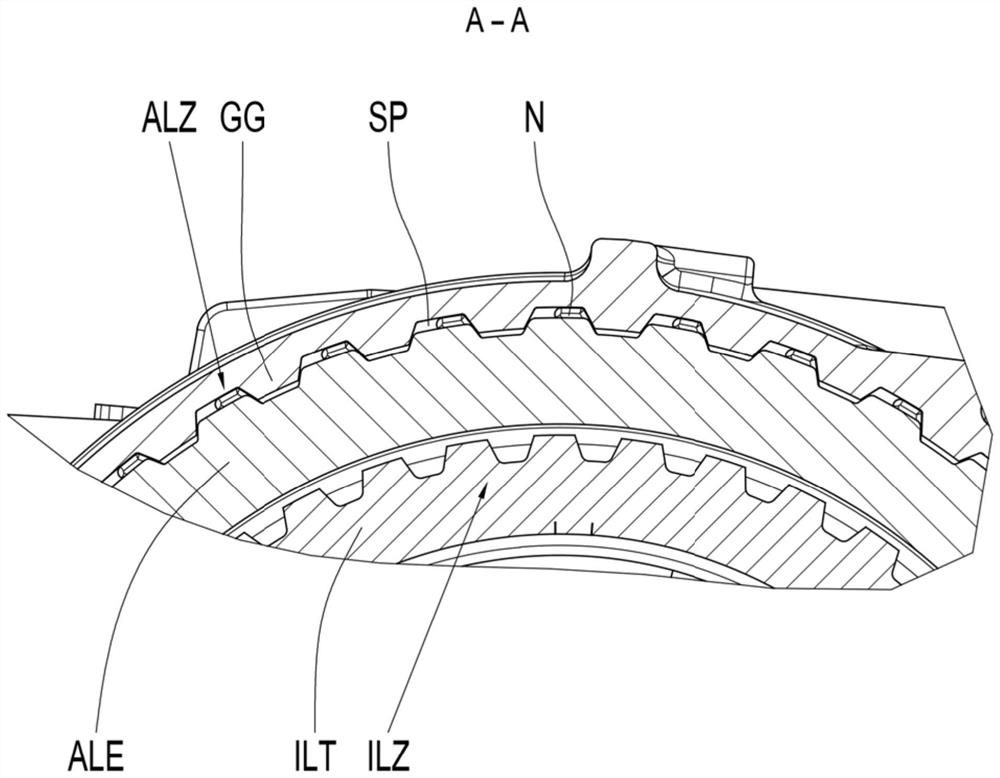

[0034] figure 1A detailed sectional view of a transmission G for a motor vehicle according to a first embodiment is shown. The transmission G has a plate clutch B that acts as a brake. A section of the housing GG of the transmission G is used here as the outer disk carrier ALT of the multi-disk clutch B. The outer linings AL, ALE are arranged axially displaceable on the outer lining carrier ALT. On its outer diameter, the ring gear HO of the planetary gear set of the transmission G forms the inner disk carrier ILT of the multi-disk clutch B. The inner lining IL is arranged axially displaceably on the inner lining carrier ILT. The inner friction plates IL and the outer friction plates AL, ALE are arranged alternately. The inner lining IL is designed as a lining friction lining. The outer friction linings AL, ALE are designed as lining-less friction linings. On one side of the multi-disk clutch B is arranged a piston K which can be displaced in the direction of the multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com