Flow-adjustable multi-stage throttling orifice device

A throttling orifice and flow adjustment technology, applied in the field of fluid transmission, can solve the problems of fixed throttling area, cavitation, and reduced component performance, and achieve the effects of reducing air noise, achieving noise reduction, and reducing cavitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

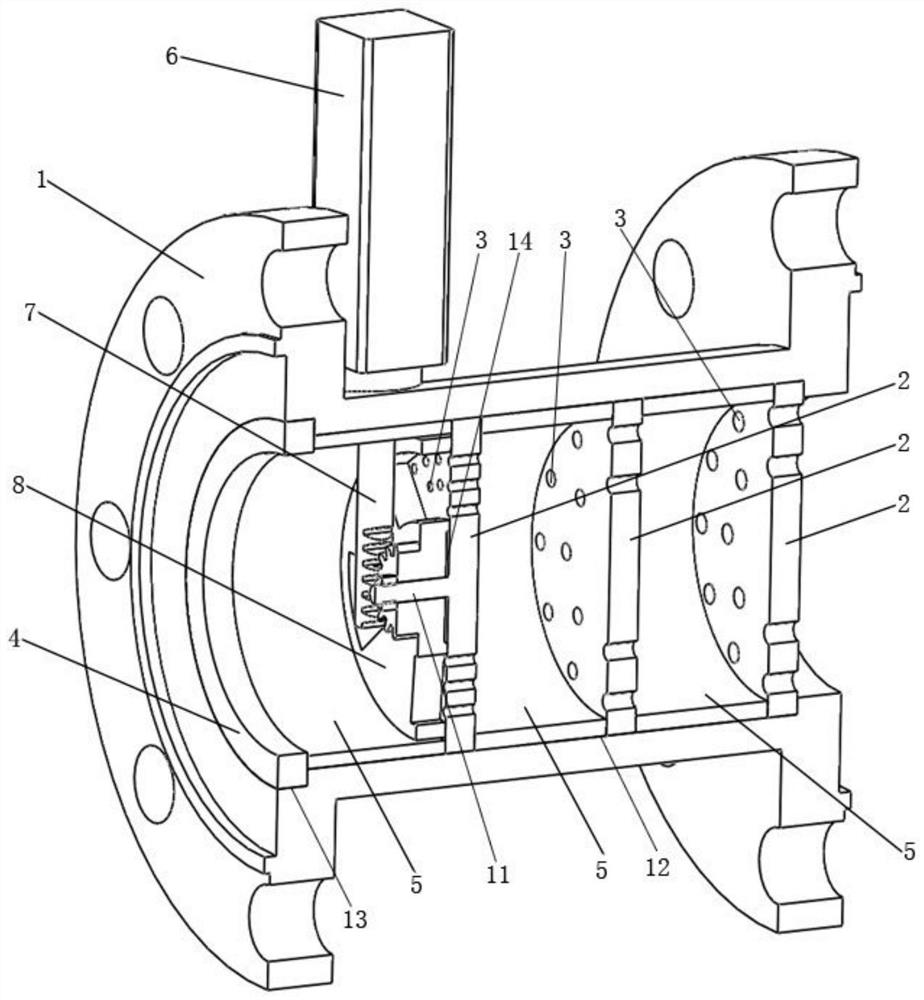

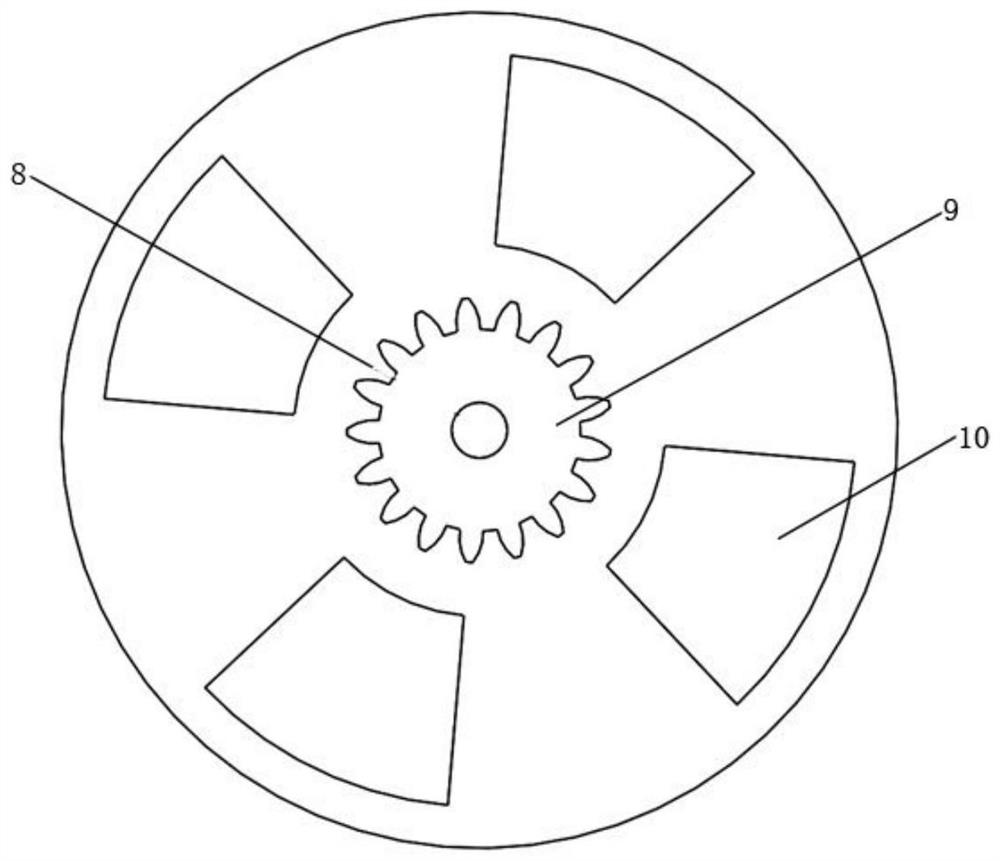

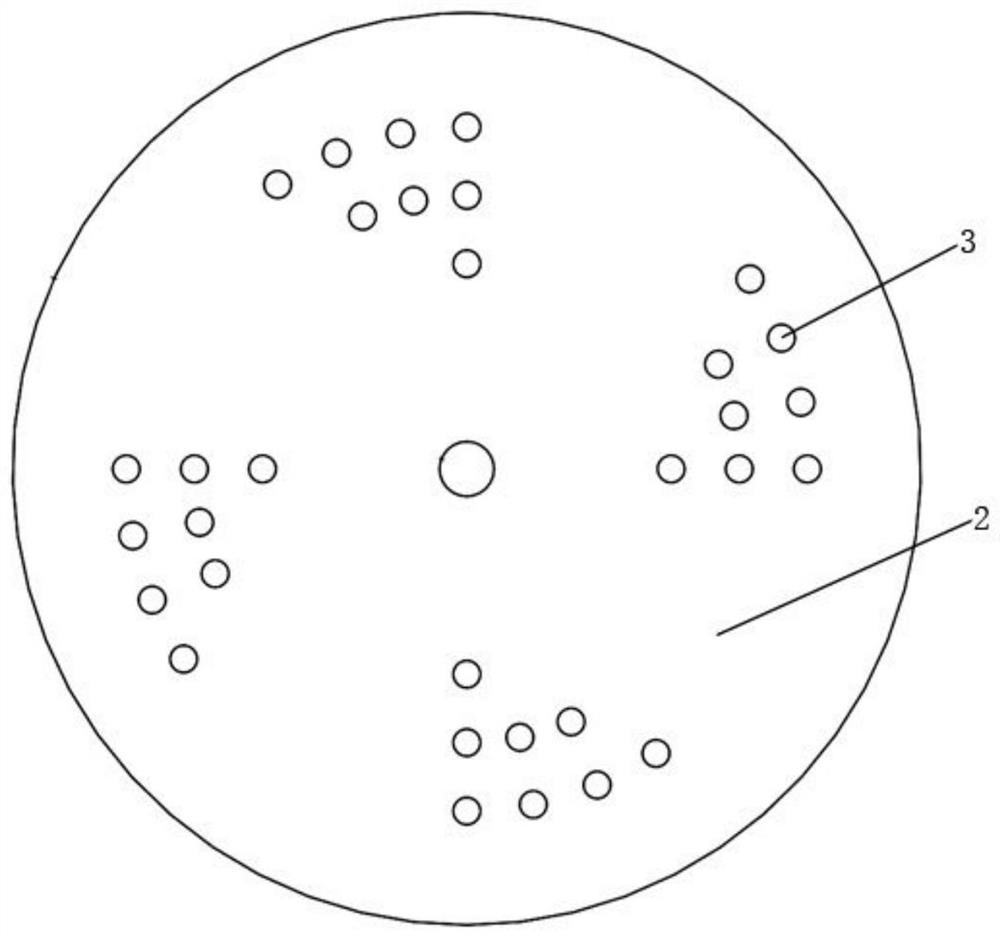

[0032] The multi-stage throttling orifice includes three throttling orifices, which are the first-stage throttling orifice, the second-stage throttling orifice and the third-stage throttling orifice, which are arranged at intervals along the fluid flow direction. The orifice area of the first-stage orifice plate is four, and each area is equipped with 8 orifices, which are arranged in four rows in the clockwise direction along the circumference, and the number of orifices in each row is 1-2. -2-3 pcs. Turn the baffle clockwise to turn the closing device to circulate, and turn counterclockwise to open the device to circulate; the rotating baffle rotates to change the flow area of the orifice of the first-stage throttle orifice to adjust the flow, and the rotation angle range is 45 degrees.

[0033] When in use, the device is initially fully open, such as Figure 4 As shown, and when the electric cylinder is not working, the transmission rack is in a contracted state and is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap