Pressure reduction linkage low-pressure release gas pressure reducer

A low-pressure release and pressure reducer technology, applied in engine components, multi-port valves, control valves, etc., can solve problems such as damage to sensitive components, shortened service life, and inability to automatically release downstream gas, achieving high reliability and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

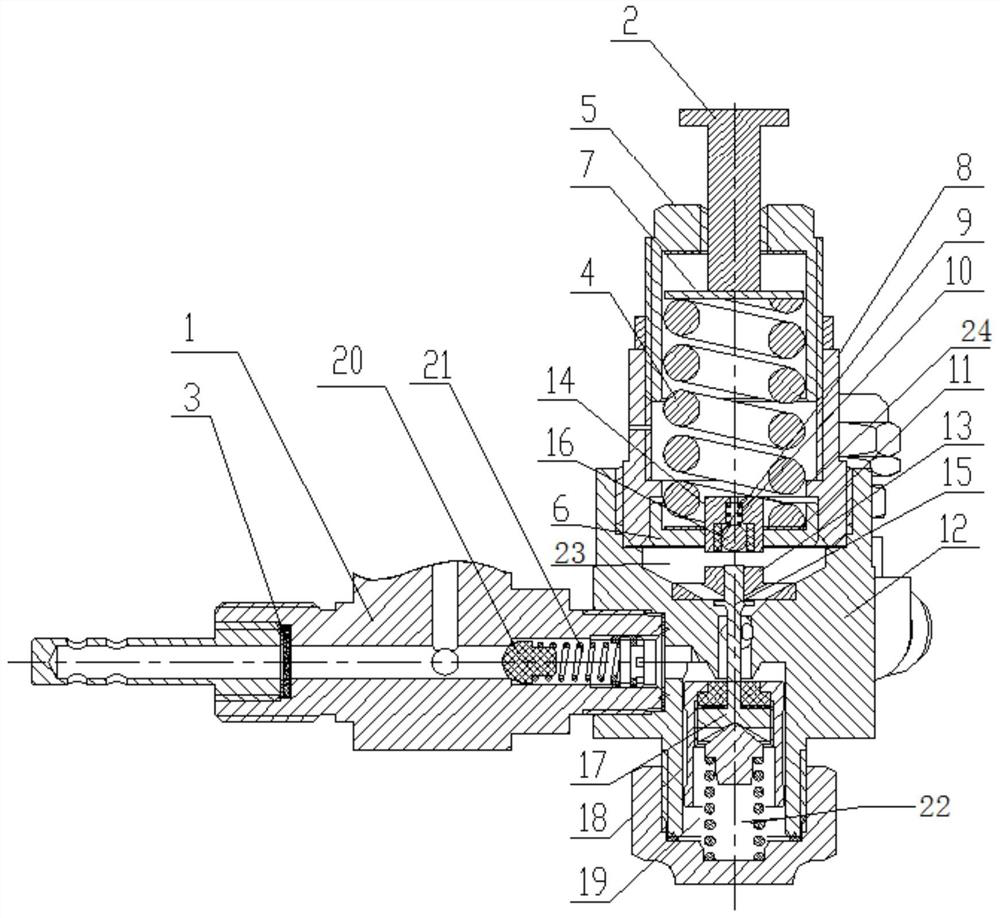

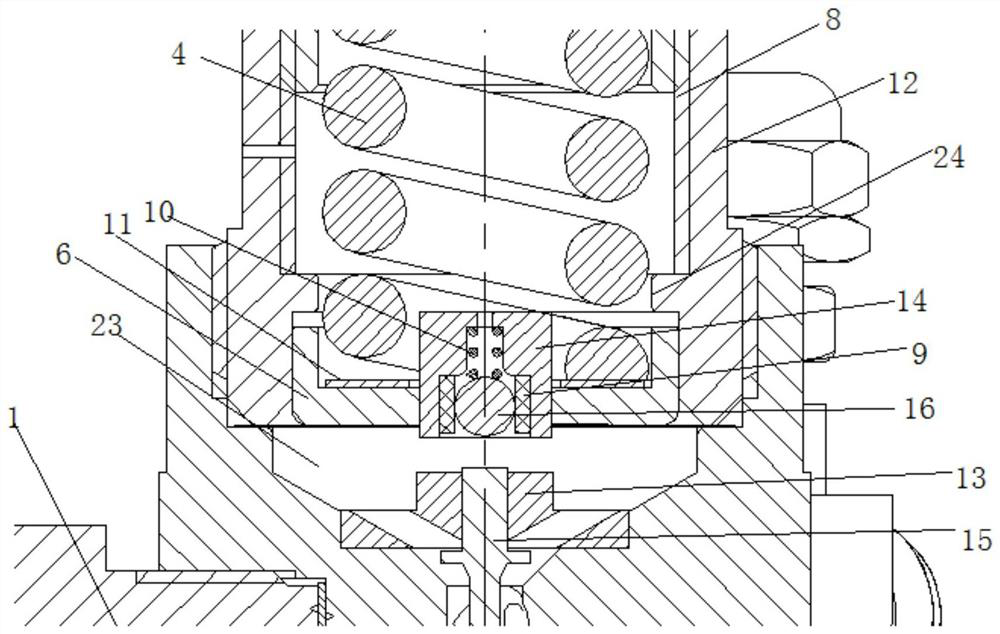

[0024] like figure 1 , 2 As shown, a decompression linkage low-pressure release gas pressure reducer includes an intake nozzle 1, a housing 12, a pressure regulating assembly and a decompression assembly;

[0025] The air intake mouthpiece 1 is installed on the air intake end of the housing 12, and the air intake mouthpiece 1 is sealed with an oxygenation valve assembly; the housing 12 is provided with a cavity 22 and a cavity Two 23; the cavity one 22 communicates with the intake nozzle 1;

[0026] The pressure regulating assembly includes an outer casing 8, a screw sleeve 5, a screw rod 2, a pressure regulating spring 4, a rubber diaphragm 6, a linkage valve assembly and a push rod 15; the upper and lower ends of the outer casing 8 are open, and the outer casing The lower end of the body 8 is threadedly connected to the inner wall of the upper end of the cavity two 23 of the housing 12, and the screw sleeve 5 is screwed to the upper end inner wall of the outer shell 8; co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com