Constraint parallel type three-dimensional force/torque sensor

A torque sensor, three-dimensional force technology, applied in the direction of measuring force components, etc., can solve problems such as weak overall stiffness, sensor damage, and reduced operating accuracy at the end of the actuator, achieving convenient solution, elimination of signal crosstalk, high linearity and The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

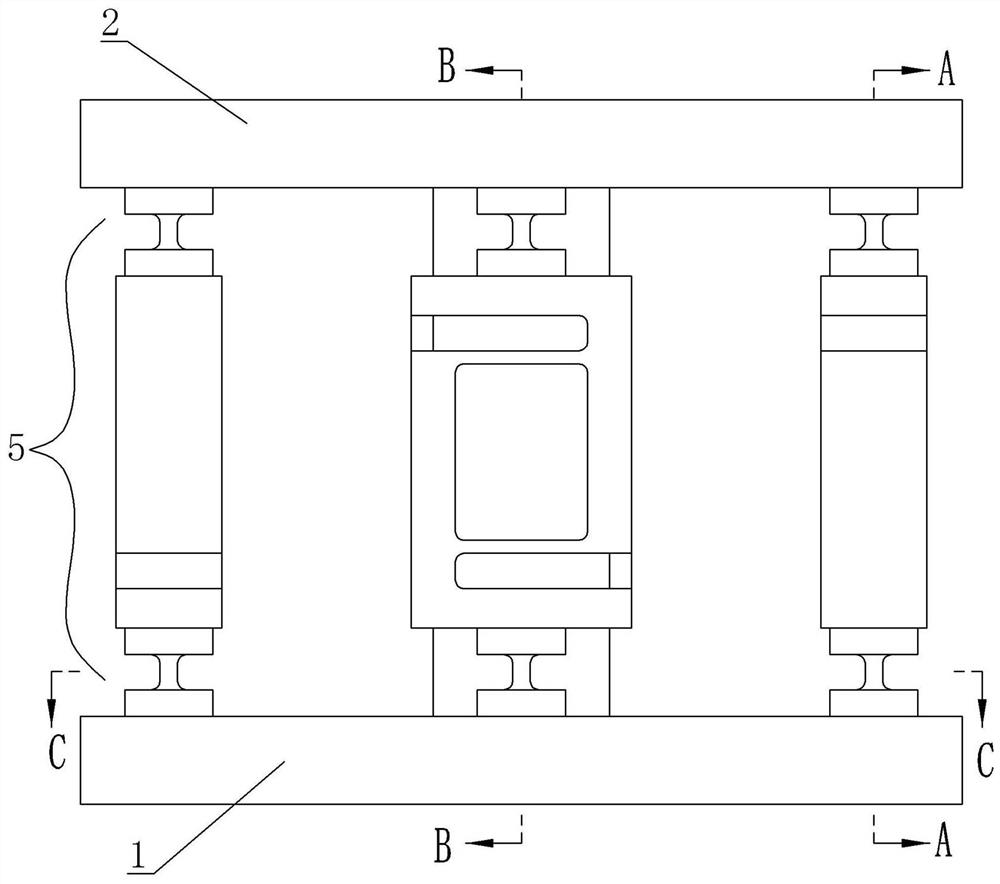

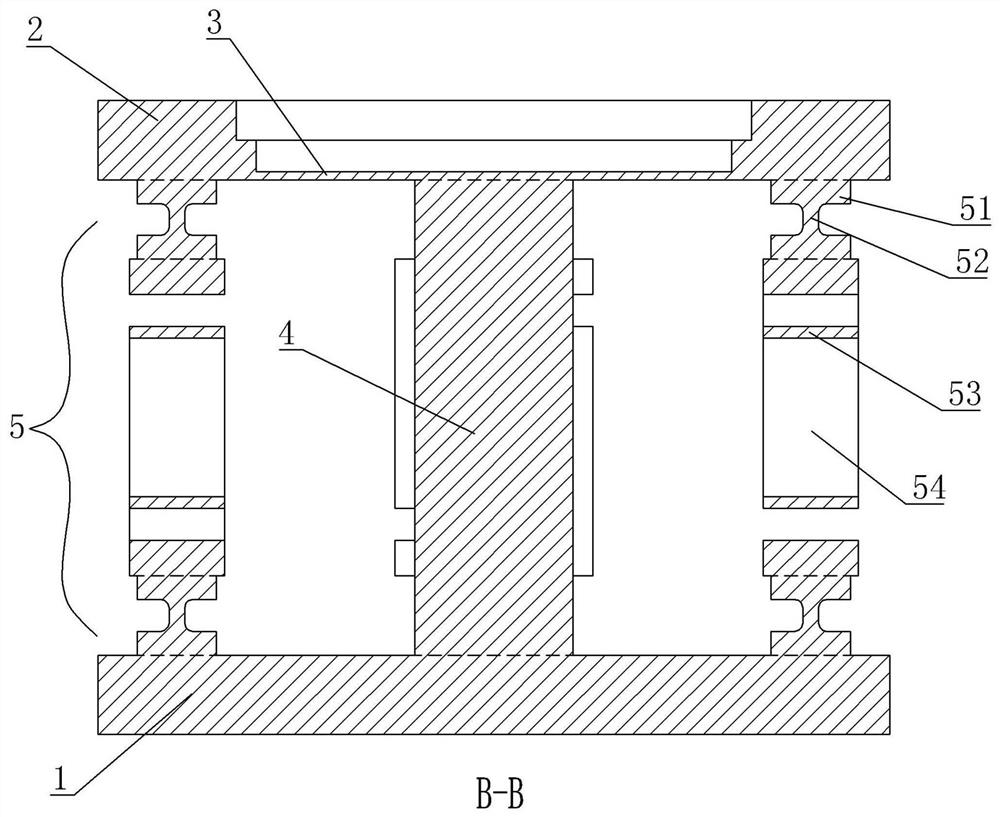

[0030] Embodiment one: see Figure 1-5 , a constrained parallel three-dimensional force / torque sensor in the figure, including a lower disk-shaped fixed platform corresponding to the center and an upper circular force loading platform, which is characterized by:

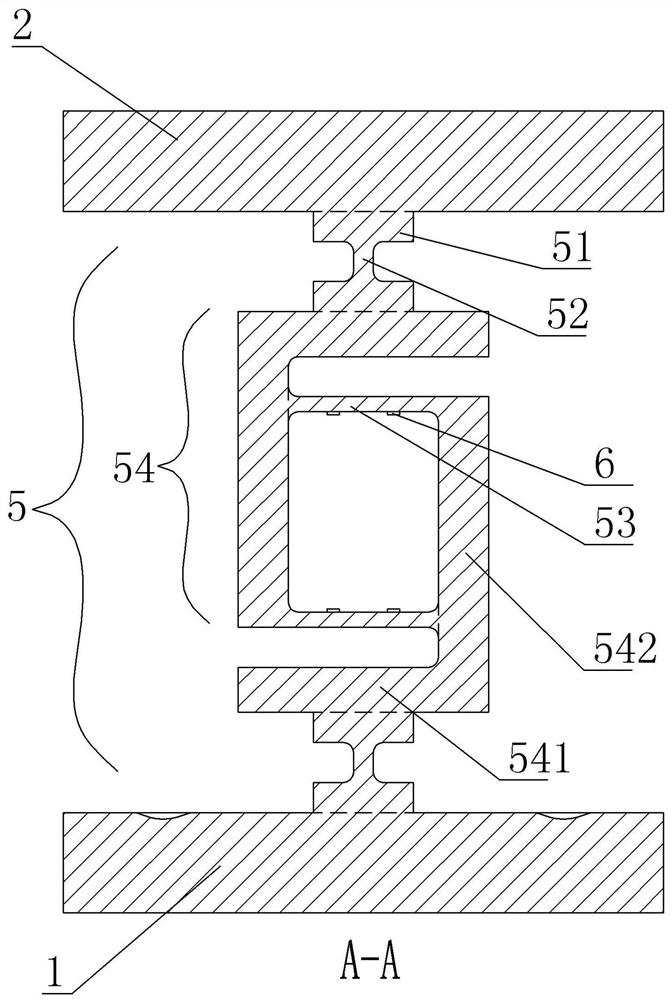

[0031] The middle part of the force loading platform is connected with a disk-shaped web, and a coaxial middle column is connected between the center of the web and the center of the fixed platform. The web can make the sensor have strong resistance to lateral force and The ability to resist torque load; through processing and adjusting the thickness of the web, the sensor's range and measurement sensitivity can be changed under the premise that the sensor configuration and branch measurement range remain unchanged

[0032] Between the upper surface of the fixed platform and the lower surface of the force loading platform, there are at least N force measurement branch chains connected, N=4, and the N force measuremen...

Embodiment 2

[0042] Embodiment two: see Figure 6-8 , the second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that in the second embodiment, at least N force measuring devices are connected between the upper surface of the fixed platform and the lower surface of the force loading platform. Branches, N=3, N force measurement branches are evenly distributed along the circumference.

[0043] In the first and second embodiments above, the sensor patch can be pasted on the opposite surfaces of the inner sides of the two rectangular thin beams, such as figure 2 shown in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com