Multi-joint self-adaptive plugging mechanism

A self-adaptive, multi-joint technology, used in the testing of machine/structural components, fluid tightness testing, measuring devices, etc., can solve the problem of uneven radial expansion of the sealing ring, abnormal wear of the sealing ring, leakage of the sealing part, etc. problem, to achieve uniform radial force, avoid bending deformation, and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

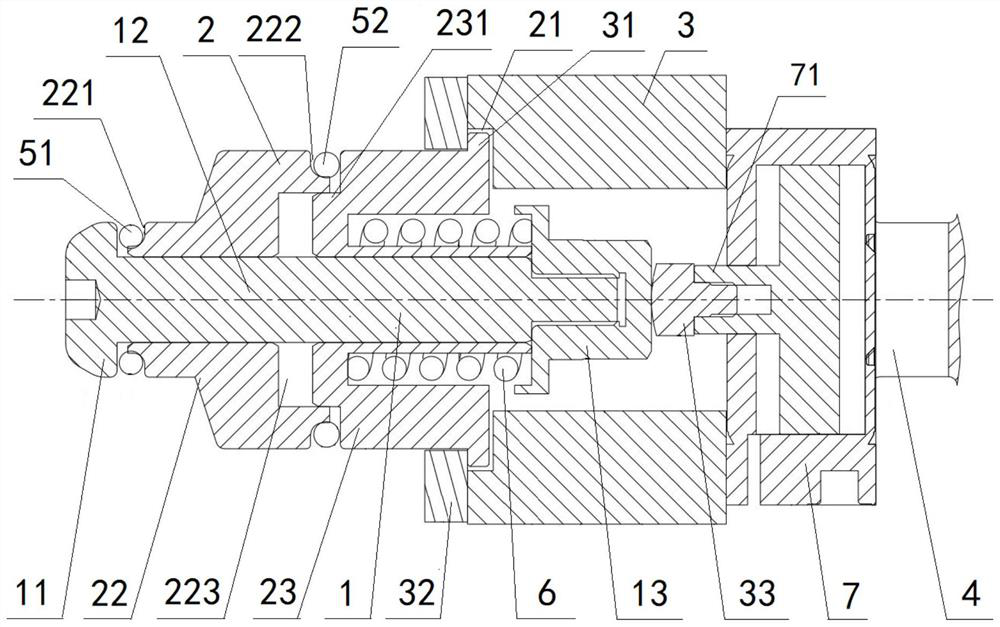

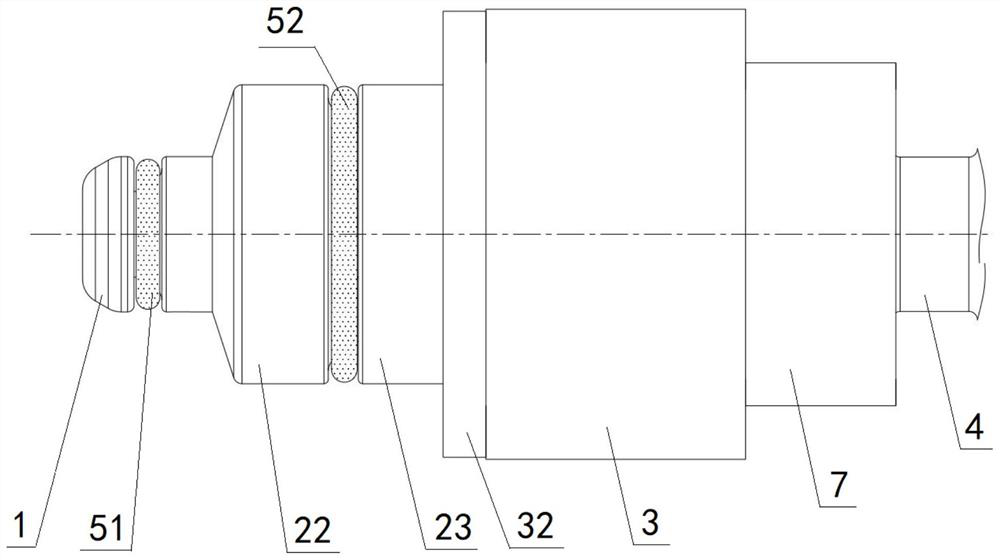

[0093] A multi-joint self-adaptive block, the self-adaptive block includes: a pushing shaft 1, a block body 2, and a casing 3; the front end of the casing 3 is provided with an annular groove 31, and the block body 2 The rear end of the housing 3 is fixedly connected with an annular baffle 21, and the annular baffle 21 is arranged in the annular groove 31. The front end of the housing 3 is fixedly provided with an annular end cover 32, and the rear end surface of the annular end cover 32 is in contact with the annular The front end face of the baffle plate 21 is limit-fitted, and a gap is provided between the outer wall of the annular baffle plate 21 and the inner wall of the annular groove 31, and a gap is provided between the inner wall of the central hole of the annular end cover 32 and the outer wall of the blocking body 2. The push-and-release shaft 1 includes a pressure block 11 and a shaft rod 12 of an integral structure, the front end of the shaft rod 12 is connected wi...

Embodiment 2

[0095] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0096] The rear end of the housing 3 is fixedly connected to the front end of the drive cylinder 7, the cylinder body of the drive cylinder 7 is fixedly connected to the support 4, and the piston rod of the drive cylinder 7 is connected to the push rod 33; The push rod 33 includes a push head 331 and a second threaded rod 332 of an integral structure, the rear end of the push head 331 is fixedly connected to the front end of the second threaded rod 332, and the front end surface of the push head 331 is a spherical surface; The piston rod of the driving cylinder 7 is provided with a second threaded hole 71 , and the second threaded hole 71 is threadedly engaged with the second threaded rod 332 .

Embodiment 3

[0098] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

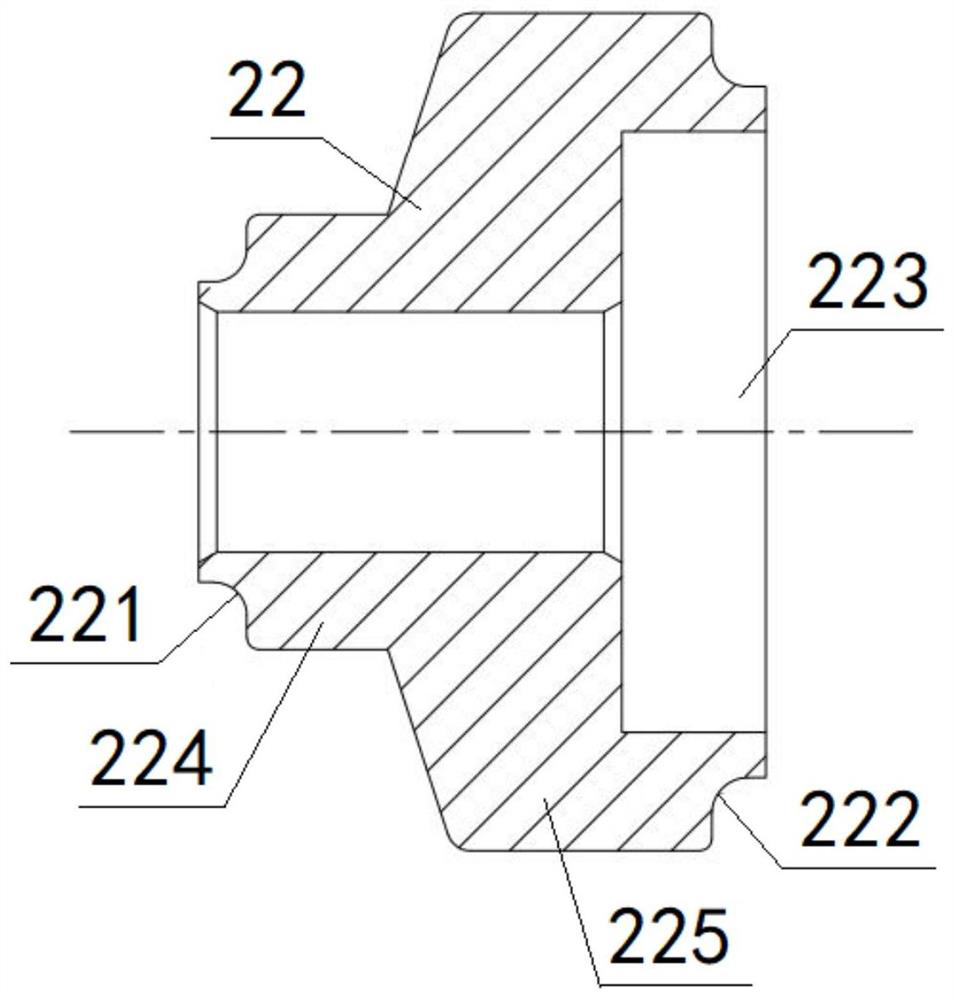

[0099] The plug 22 includes a first cylinder 224 and a second cylinder 225 of an integral structure, the rear end of the first cylinder 224 is fixedly connected to the front end of the second cylinder 225, and the first cylinder 224 is connected to the second cylinder 225. The cylinders 225 are coaxially arranged, the diameter of the first cylinder 224 is smaller than the diameter of the second cylinder 225; the first cylinder 224 and the second cylinder 225 are both sleeved on the outside of the shaft 12, and the first cylinder 224 and the second cylinder 225 are both slidingly fitted with the shaft rod 12, the front end of the first cylinder 224 is limitedly matched with the rear end of the pressure block 11, and the rear end of the second cylinder 225 is provided with a counterbore 223 ; The first sealing ring installation groove 221 is opened at the front end of the first cylinder 224, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com