Device and method for testing fluid-structure interaction effect of flexible riser under internal and external flow clamping

A technology of fluid-solid coupling and flexible risers, which is applied in the field of test devices for fluid-solid coupling effects of flexible risers, to achieve the effect of improving experimental efficiency and enriching experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

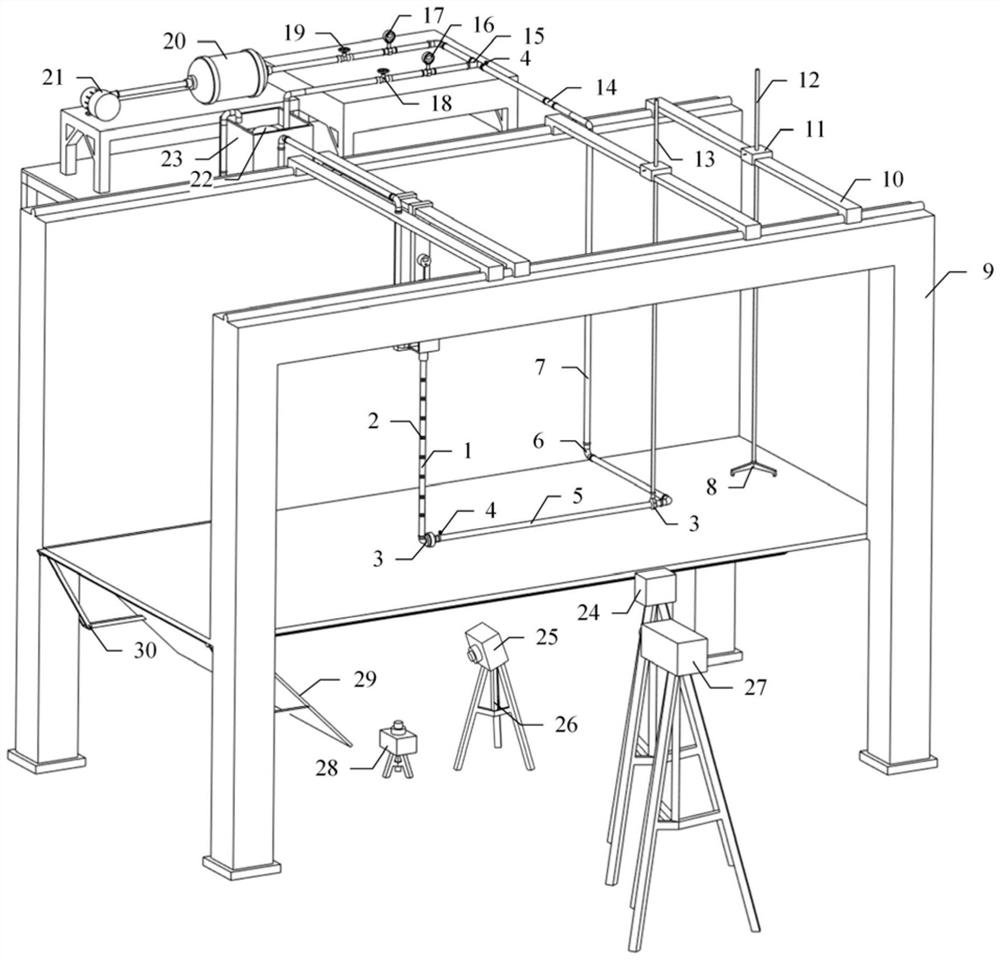

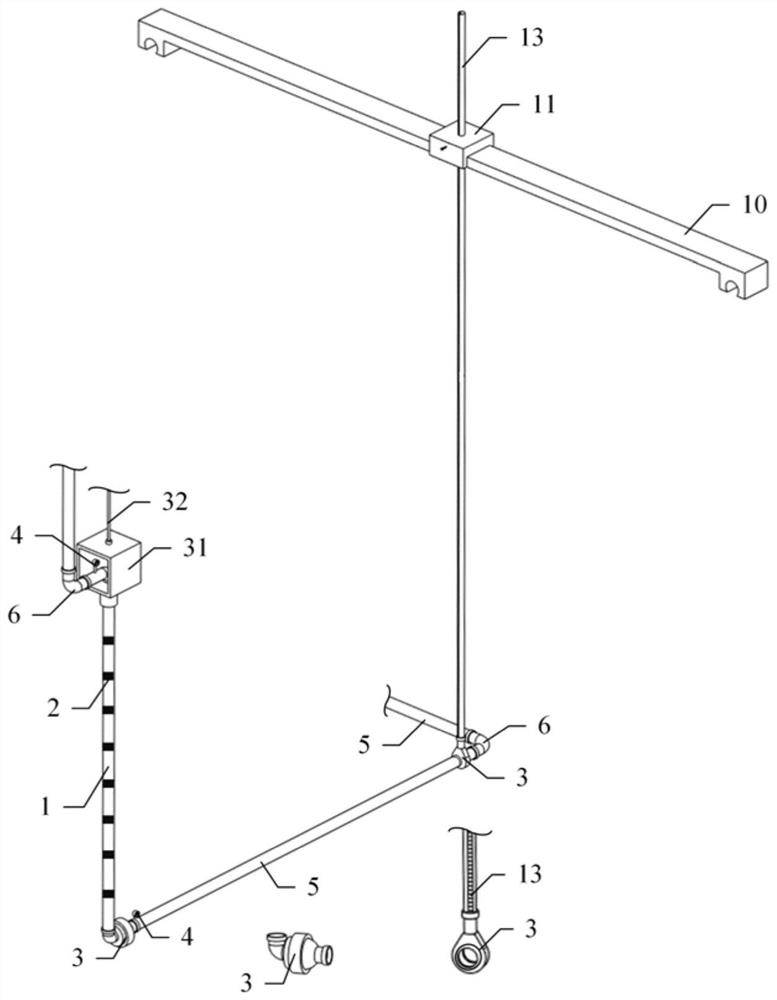

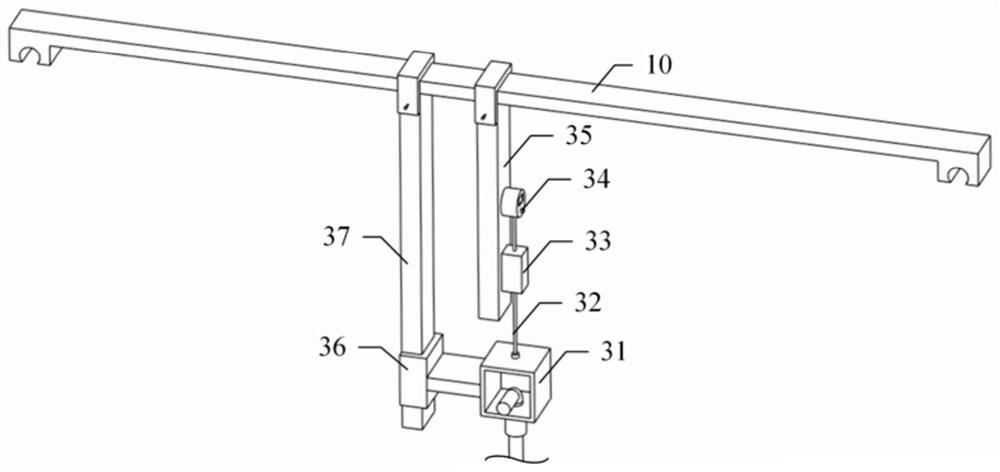

[0026] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, a flexible standpipe fluid-solid coupling effect test device for internal and external flow pinching is composed of a standpipe model 1, an upstream pipe section inclination adjustment system, a tension test module, an internal flow circulation system, a flow field monitoring system, a vibration monitoring system and The data acquisition terminal is composed, and the main body of the device is arranged in the circulating water tank 9 . The riser model 1 is a transparent hose with black marks 2 uniformly marked on the outer wall along the axial direction, and is used to simulate a flexible riser. The riser model 1 is arranged perpendicular to the central axis of the bottom wall of the circulating water tank 9, the top of the riser model 1 is fixedly connected to the bottom of the top tension fixture 31, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com