High and low temperature alternating experiment box

A kind of experiment box, high and low temperature technology, applied in the direction of laboratory appliances, instruments, measuring devices, etc., to achieve the effect of reducing power consumption, good practicability, and convenient operation

Pending Publication Date: 2022-06-10

无锡浩平科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the existing high and low temperature alternating test chambers have fewer functions and cannot adjust the internal pressure, so that it is impossible to simulate the use of the product in different pressure environments, resulting in testing The result is not accurate, now provide a high and low temperature alternating experiment box

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

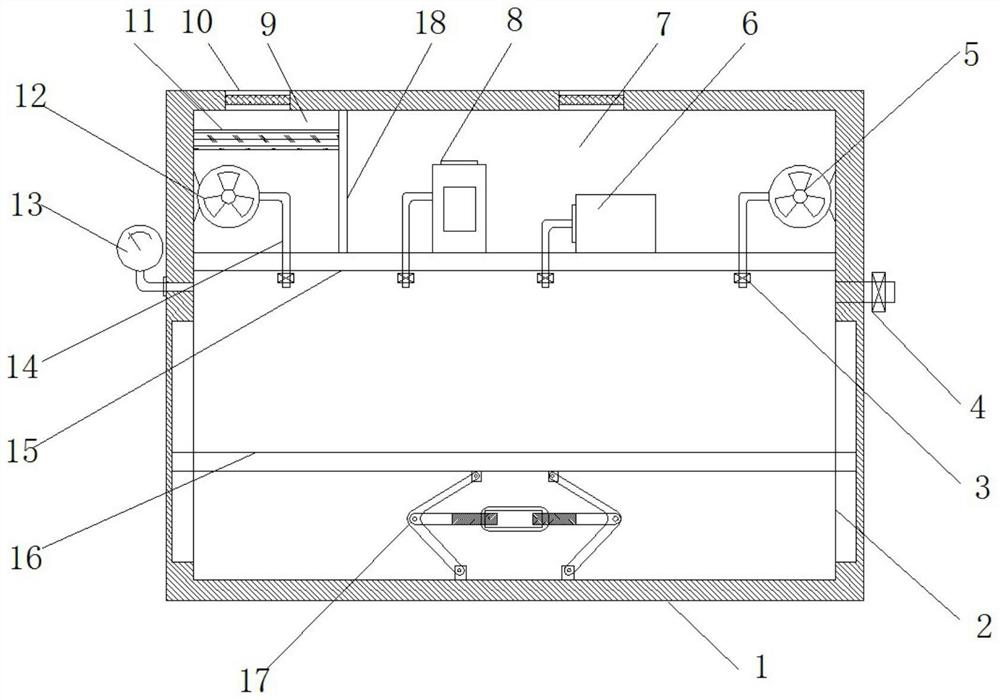

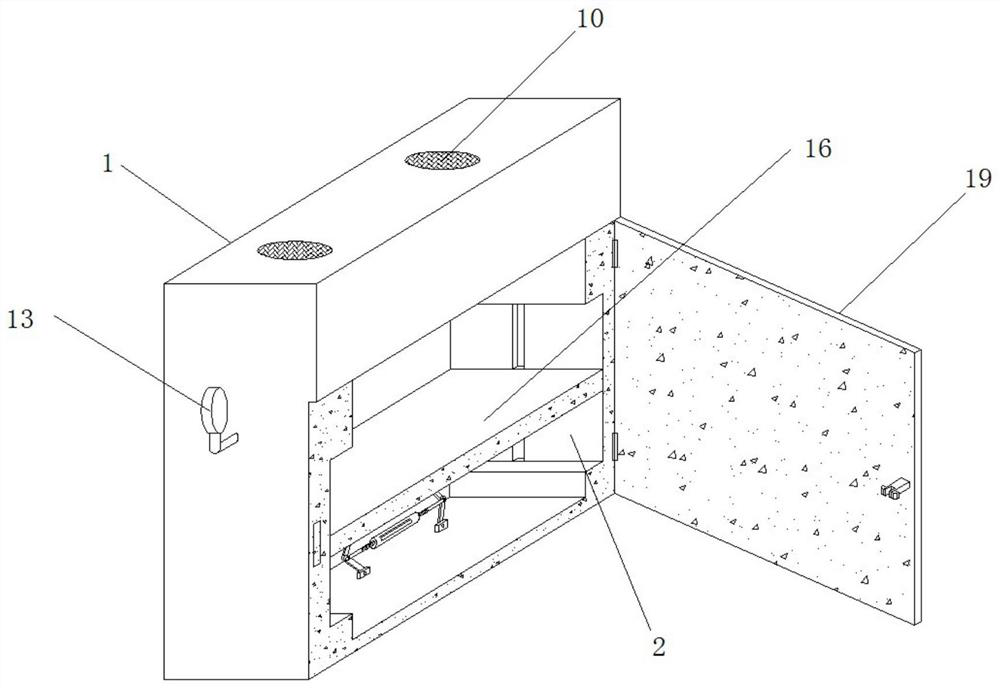

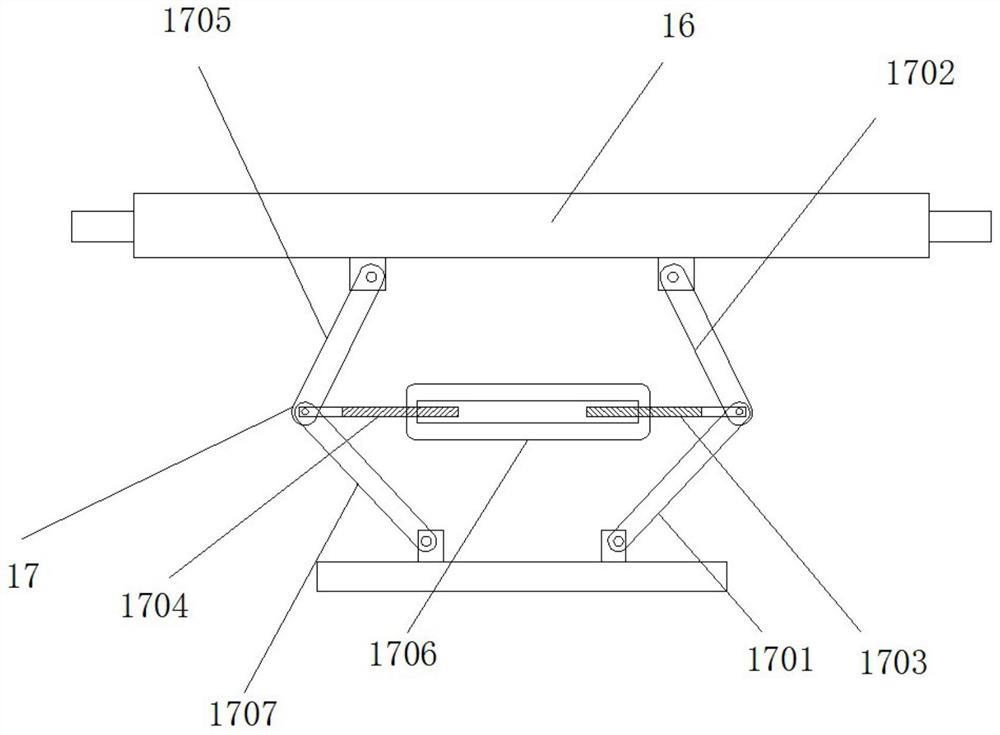

The invention discloses a high and low temperature alternating experiment box which comprises a box body, a first partition plate is installed on the upper portion of the interior of the box body, a second partition plate is installed on one side of the top end of the first partition plate, a heating cavity is formed in one side of the second partition plate, an equipment cavity is formed in the other side of the second partition plate, and an electric heating wire is installed on the upper portion of the interior of the heating cavity. An air blower is installed on the inner side of the heating cavity through a fixing base, one end of an air pipe connected with the air outlet end of the air blower penetrates to the position below the first partition plate and is provided with an electromagnetic valve, and a refrigerator body, a high-pressure air pump and an air extractor are installed in the equipment cavity through fixing bases. According to the device, the space where the product is placed above the bearing plate is heated, cooled, pressurized and decompressed, so that high-temperature testing, low-temperature testing, high-pressure testing and low-pressure testing of the product are achieved, a part of severe natural environment is well simulated, experimental detection of the product is achieved, and the device is simple in structure, convenient to operate and high in practicability. And the practicability is good.

Description

technical field [0001] The invention relates to the technical field of experimental equipment, in particular to a high and low temperature alternating experiment box. Background technique [0002] High and low temperature alternating test chamber is used in electronic and electrical components, automation components, communication components, auto parts, metals, chemical materials, plastics and other industries, defense industry, aerospace, military industry, BGA, PCB base plate, electronic chip IC semiconductor ceramics And the physical changes of polymer materials, testing the material's repeated resistance to high and low temperature and the chemical changes or physical damage of the product's thermal expansion and contraction can confirm the quality of the product. [0003] However, the existing high and low temperature alternating test chambers have fewer functions and cannot adjust the internal pressure, so that it is impossible to simulate the use of the product in di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N17/00B01L7/00B01L1/00

CPCG01N17/002B01L1/00B01L7/00

Inventor 陈中云

Owner 无锡浩平科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com