Rotary type erosion corrosion test device

A technology for scouring corrosion and testing equipment, which is applied to measuring equipment, testing wear resistance, instruments, etc., can solve the problems of high testing cost, large solution, splashing, etc., and achieve high temperature testing, easy container cleaning, and convenient disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

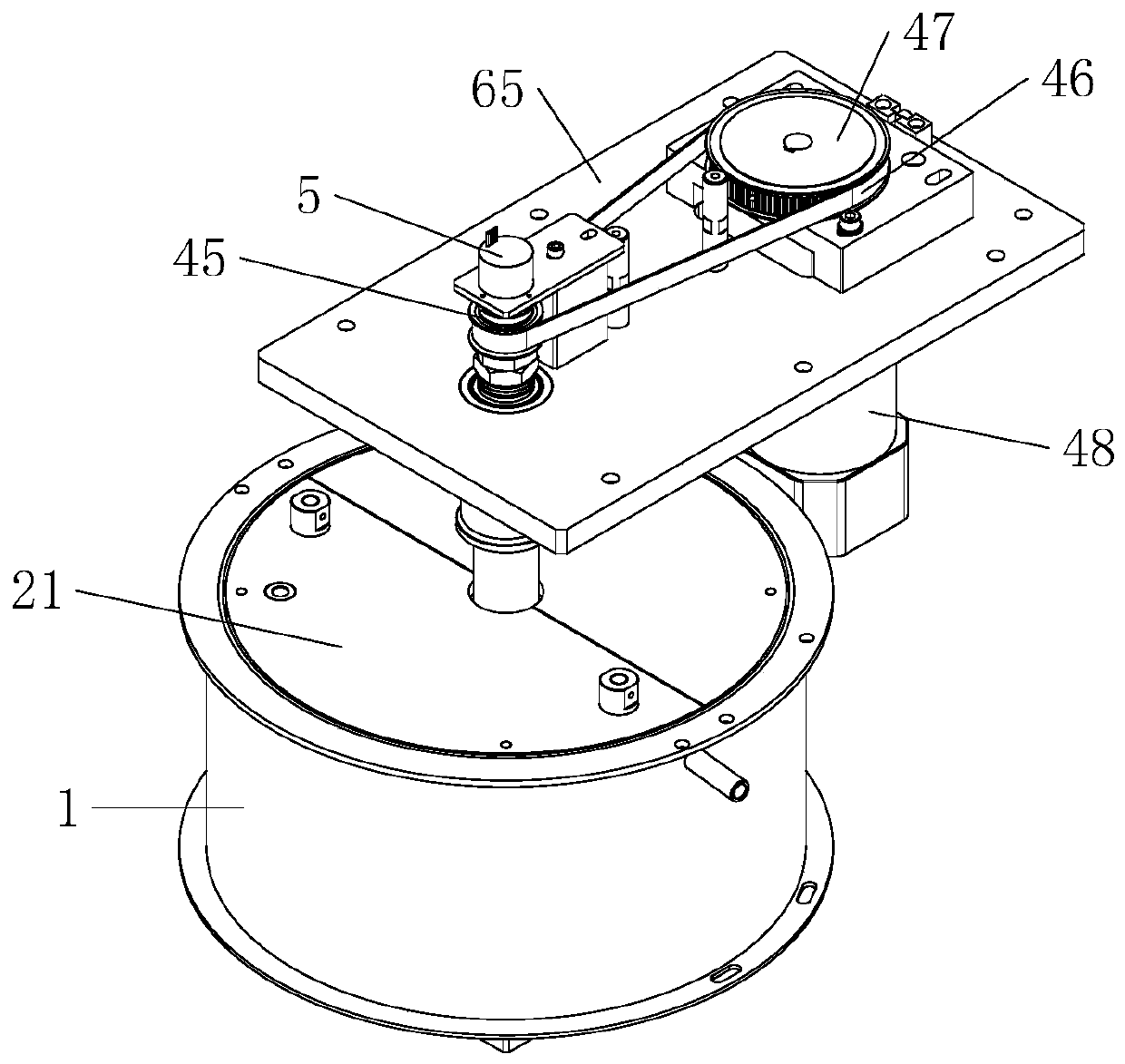

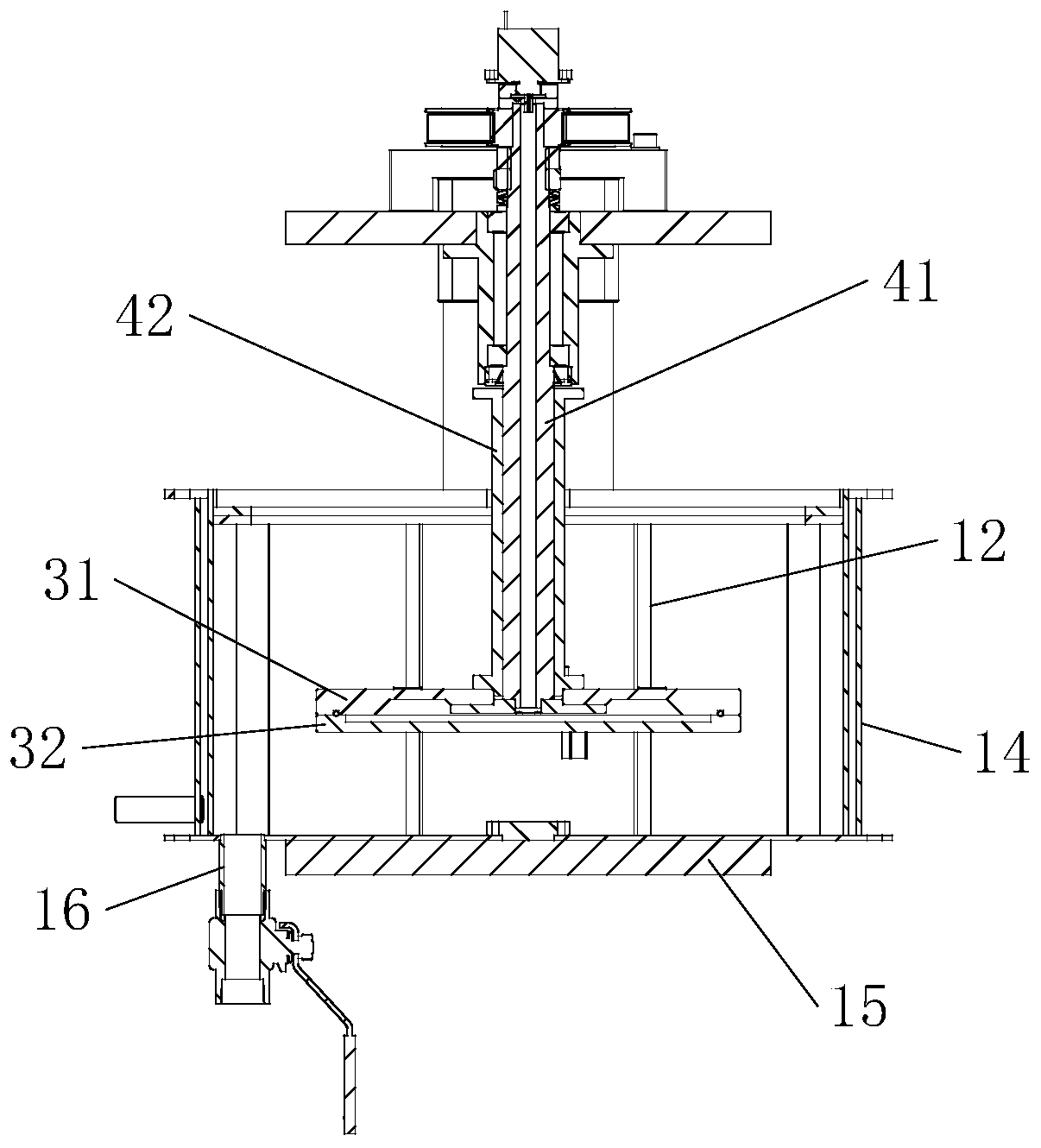

[0047] Such as Figure 1 to Figure 11 As shown, a rotary erosion corrosion test device includes a container 1, a motor 48 and an electrode 24, and the electrode 24 is located in the container 1; it also includes a rotating disk, which is located in the container 1; On the rotating disk, there are multiple sample fixing devices for fixing the sample 30; the transmission shaft, one end of the transmission shaft is connected with the rotating disk, and the other end is connected with the motor 48; and the conductive device, the conductive device is installed on the transmission shaft and On the rotating disk, and located inside the transmission shaft and the transmission disk, the conductive device is used for communication between the sample 30 and the electrochemical testing device.

[0048] Through the high-speed rotation of the sample 30 in the test solution to simulate the situation of pumps, blades and other high-speed propulsion medium flow channels, which is basically clo...

Embodiment 2

[0076] On the basis of the first embodiment above, the bottom of the lower turntable 32 is provided with a stirring plate 39 , and there are multiple stirring plates 39 in an annular array, and the stirring plate 39 is used to stir the gravel at the bottom of the container 1 .

[0077] The stirring plate 39 stirs the gravel at the bottom of the container 1 to prevent the gravel from gathering in the middle of the bottom of the container 1, because the test solution at the center of the container 1 rotates slowly when the test solution in the container 1 rotates, causing the gravel to accumulate and cause the scour area The sand content of the test solution is low, and the stirring plate 39 can stir the gravel at the bottom of the container 1 to improve the sand content in the scoured area.

Embodiment 3

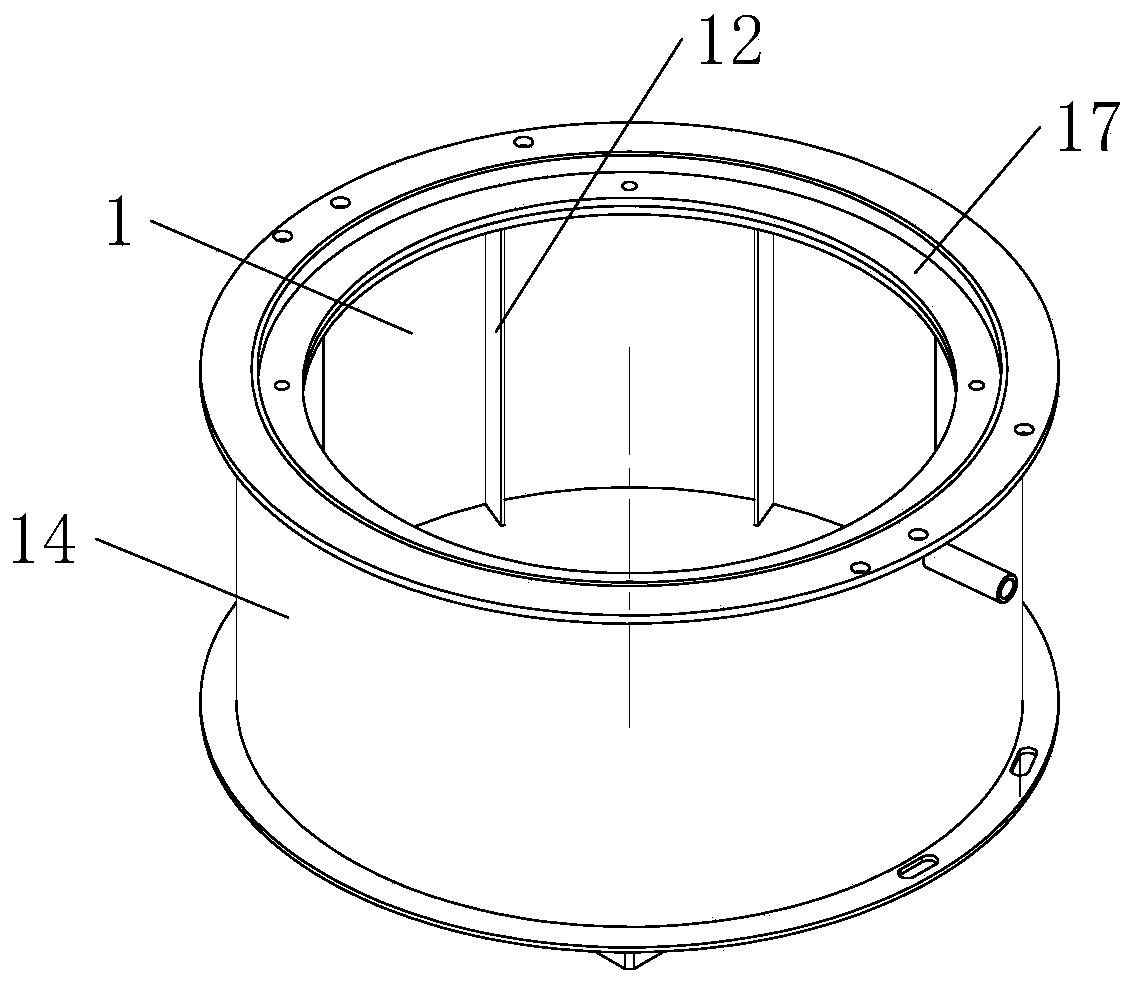

[0079] On the basis of the above-mentioned embodiment one or embodiment two, as image 3 and Figure 4 As shown, the container 1 is cylindrical, with an opening at the top and a closed bottom. The interior of the container 1 is provided with spoilers 12 , and a plurality of spoilers 12 are arranged in a circular array along the axis of the container 1 .

[0080] The spoiler 12 makes the test solution form a vortex, and the direction of rotation of the vortex is opposite to the direction of rotation of the rotating disk. The direction of rotation of the test solution is consistent with that of the rotating disk, but the rotational speed of the test solution is far less than that of the rotating disk, and the disturbing The direction of rotation of the vortex formed by the flow plate 12 is opposite to the direction of rotation of the test solution, so it forms a larger speed difference with the sample 30, and the sample 30 on the rotating disk passes through the vortex, thus great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com