Calibration piece preparation method and calibration piece

A technology for calibrating parts and cross-sectional dimensions, applied in measuring devices, instruments, measuring electrical variables, etc., can solve problems such as calibration parts deviation, and achieve the effect of overcoming deviation, improving design success rate and efficiency, and increasing attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In the following description, specific details such as specific system structures and technologies are presented for illustration rather than limitation, so as to thoroughly understand the embodiments of the present invention. It will be apparent, however, to one skilled in the art that the invention may be practiced in other embodiments without these specific details. In other instances, detailed descriptions of well-known systems, devices, circuits, and methods are omitted so as not to obscure the description of the present invention with unnecessary detail.

[0057] In order to make the purpose, technical solution and advantages of the present invention clearer, specific embodiments will be described below in conjunction with the accompanying drawings.

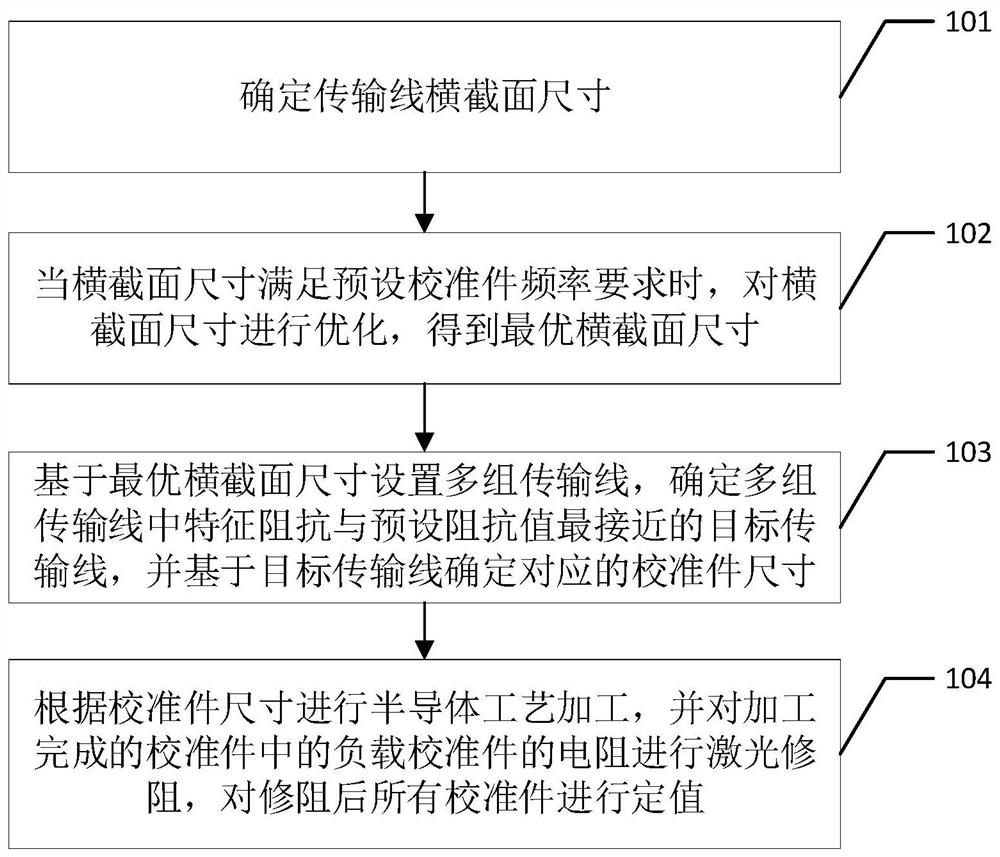

[0058] figure 1It is an implementation flow chart of a method for preparing a calibrator provided in an embodiment of the present invention. The calibrator generally includes five types of calibrator: SOLT, LRRM, LR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com