Rolling bearing fault diagnosis method and system

A rolling bearing and fault diagnosis technology, which is applied in the direction of instruments, character and pattern recognition, computer components, etc., can solve the problems of secondary feature extraction to remove redundant information, difficulty in rolling bearing fault feature extraction, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

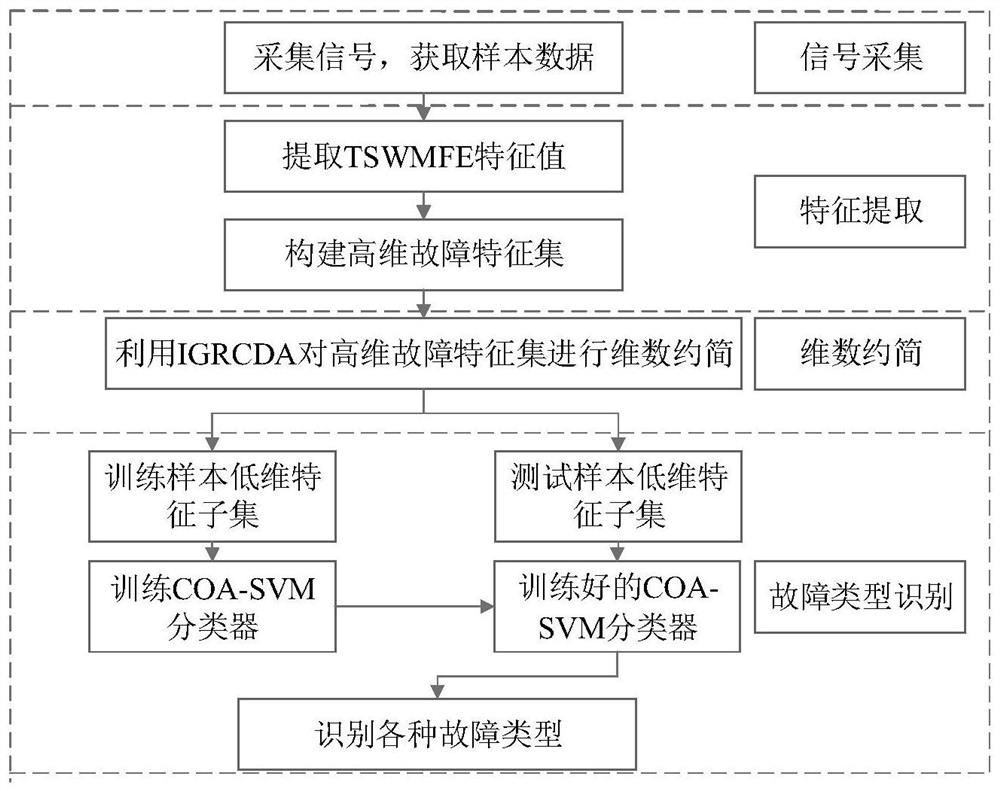

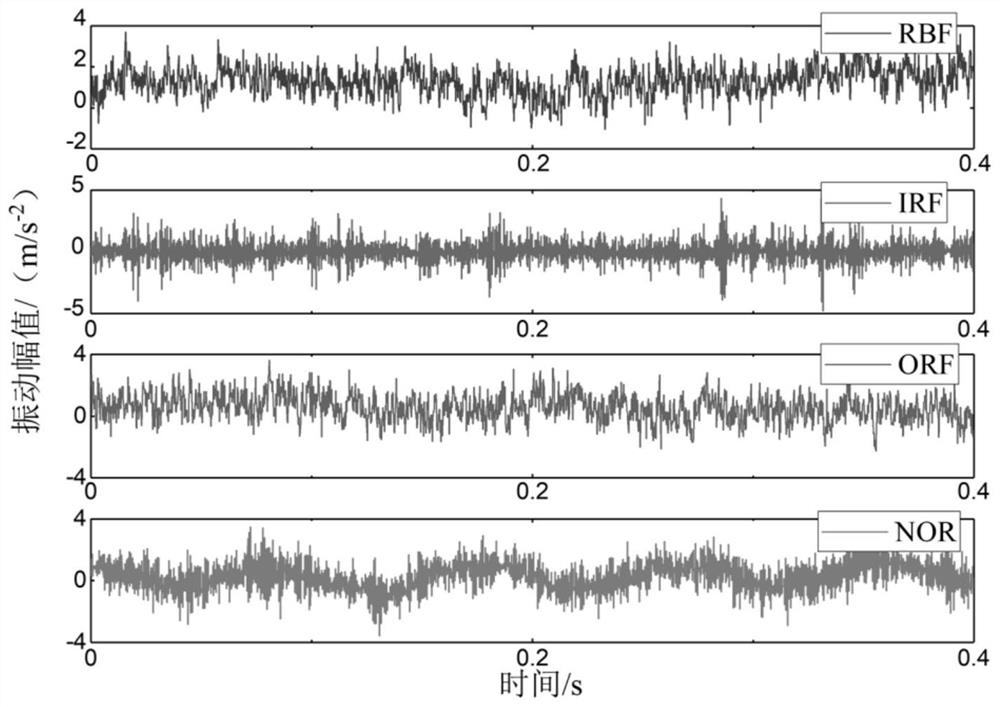

[0065] Such as figure 1 As shown, this embodiment provides a technical solution: a rolling bearing fault diagnosis method, using the rolling bearing signal data collected by the BVT-5 bearing fault measuring instrument (fault experiment platform) as an example to verify the method. Among them, the motor speed is 1800r / min, the sampling frequency is 5120HZ, and the sampling points are set to 2048 sampling points, including the following steps:

[0066] S1: collect different fault state signals of rolling bearings;

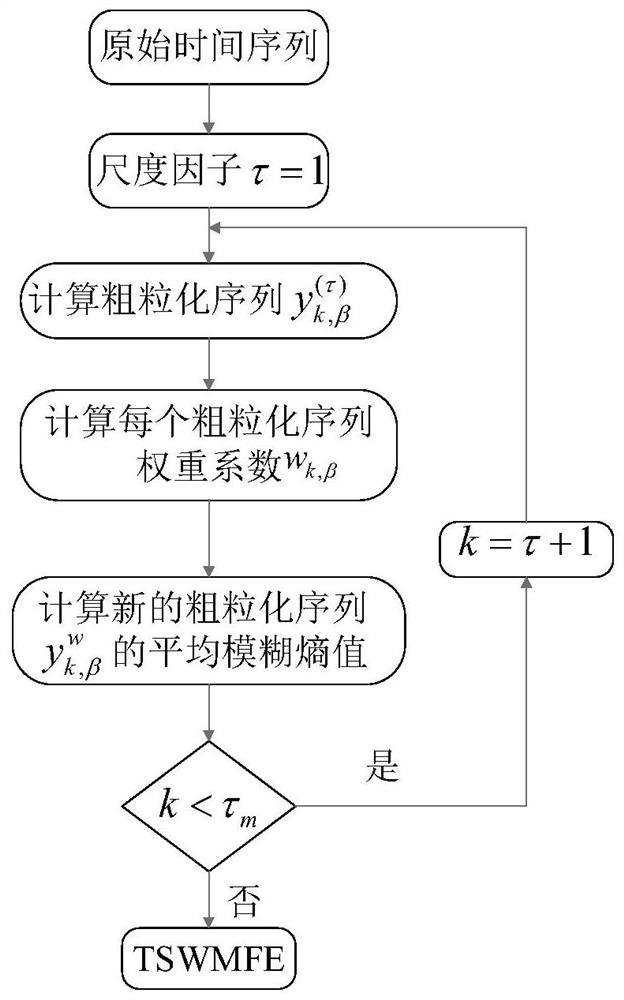

[0067] S2: Use the time-shift weighted multi-scale fuzzy entropy algorithm TSWMFE to extract fault ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com