Flexible manufacturing workshop demand response scheduling method based on hierarchical game

A technology of demand response and scheduling method, which is applied in the direction of sustainable manufacturing/processing, artificial life, climate sustainability, etc. It can solve the problems of lack of general demand response model for discrete manufacturing and the difficulty of establishing a discrete model mathematical model, etc., to improve Convergence and diversity, the effect of reducing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

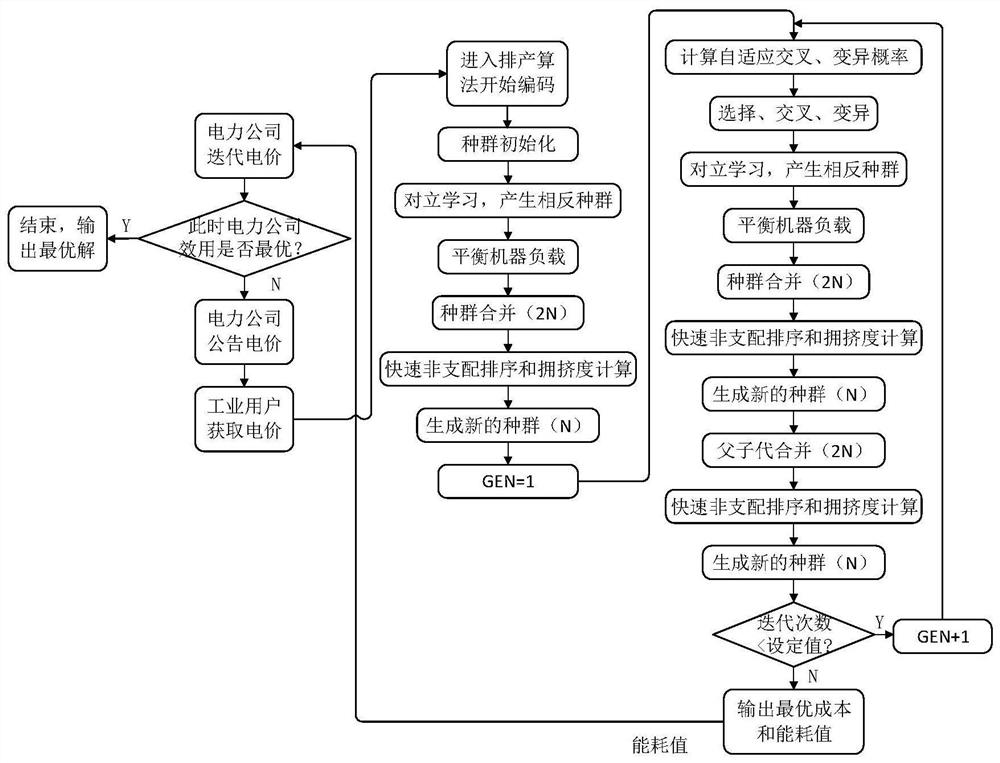

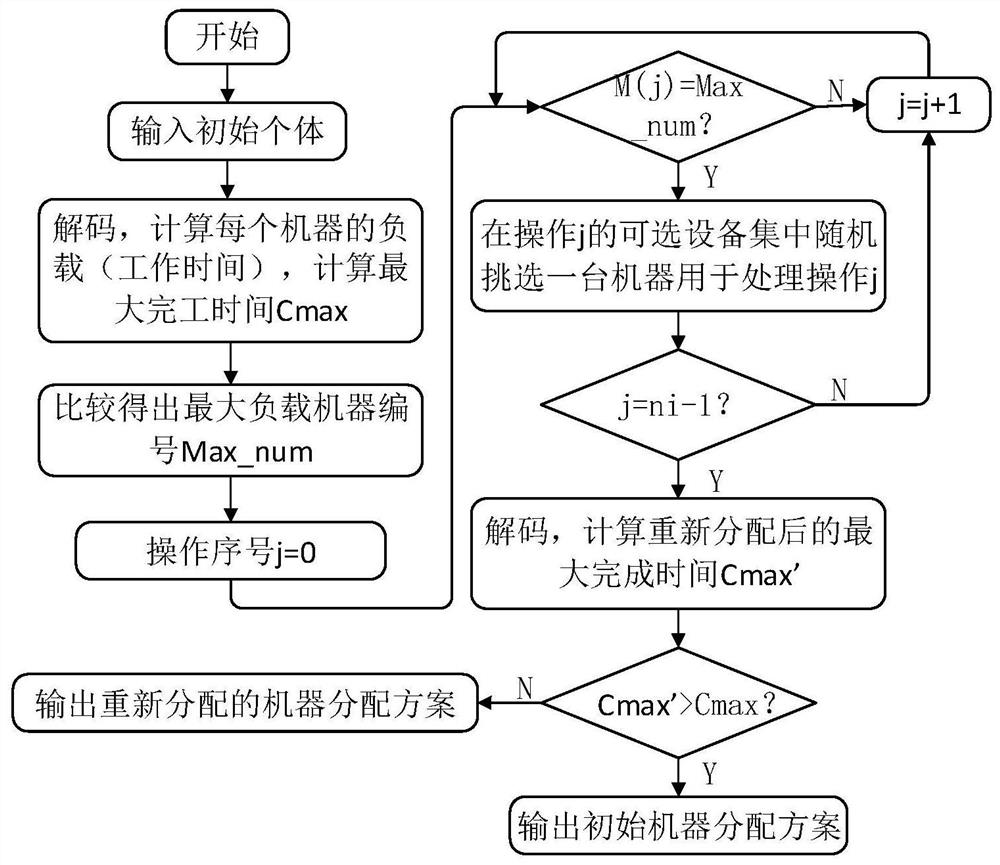

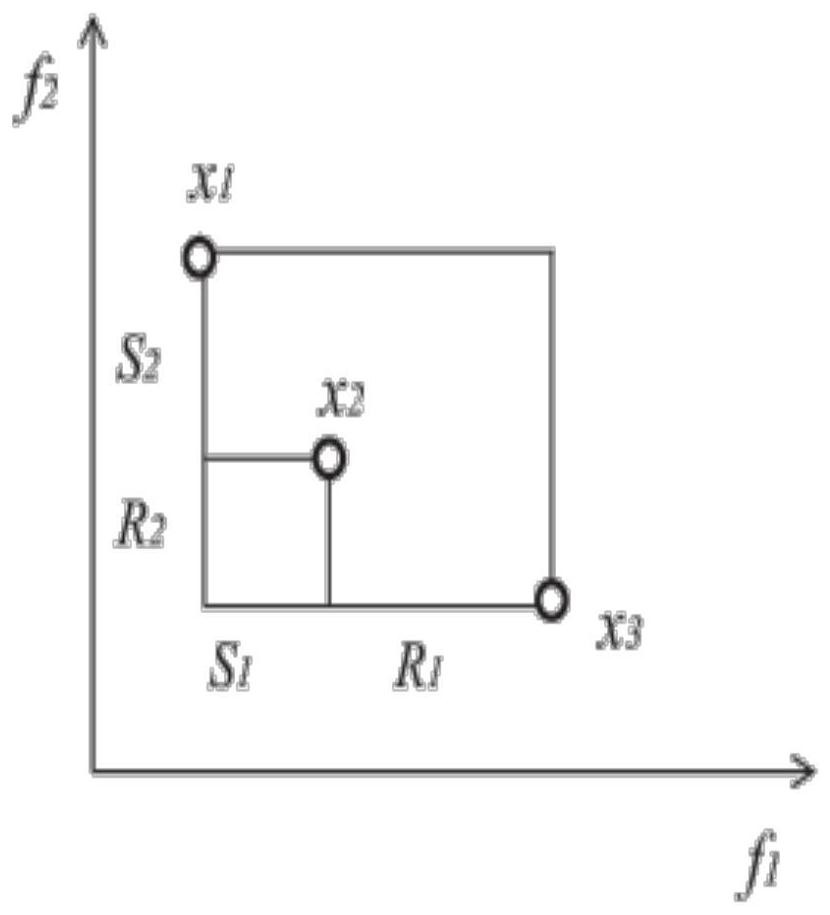

[0059] The present invention provides a flexible manufacturing workshop demand response scheduling method based on layered game, constructing a flexible manufacturing workshop production scheduling management and control model based on time-of-use electricity price on the traditional job workshop scheduling model; on the basis of NSGA-II algorithm Aiming at the convergence and diversity of the algorithm, the opposite learning strategy and the adaptive crossover and mutation probability strategy are introduced, and the machine load balancing strategy is adopted for the machine load balancing problem. The specific process is as figure 1 shown, including the following steps:

[0060] S1. Establish a flexible job shop production scheduling control model (FJSP model) based on time-of-use electricity price, and take the maximum profit of the power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com