Method and system for generating wine bottle defect samples based on deep neural network

A deep neural network and wine bottle technology, which is applied in the field of defect sample generation, can solve problems such as inability to generate high-efficiency and large-scale wine bottle defect samples, inapplicability to large-scale production of wine bottle surface defect detection, and inability to collect a large number of problems. Generate problems on a large scale, save manpower, and improve generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

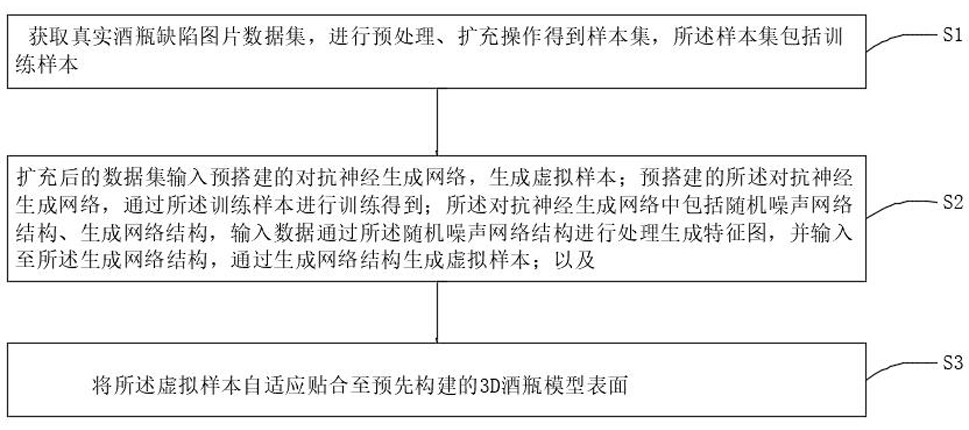

[0077] Before describing the wine bottle defect sample generation method based on deep neural network, the following needs to be explained:

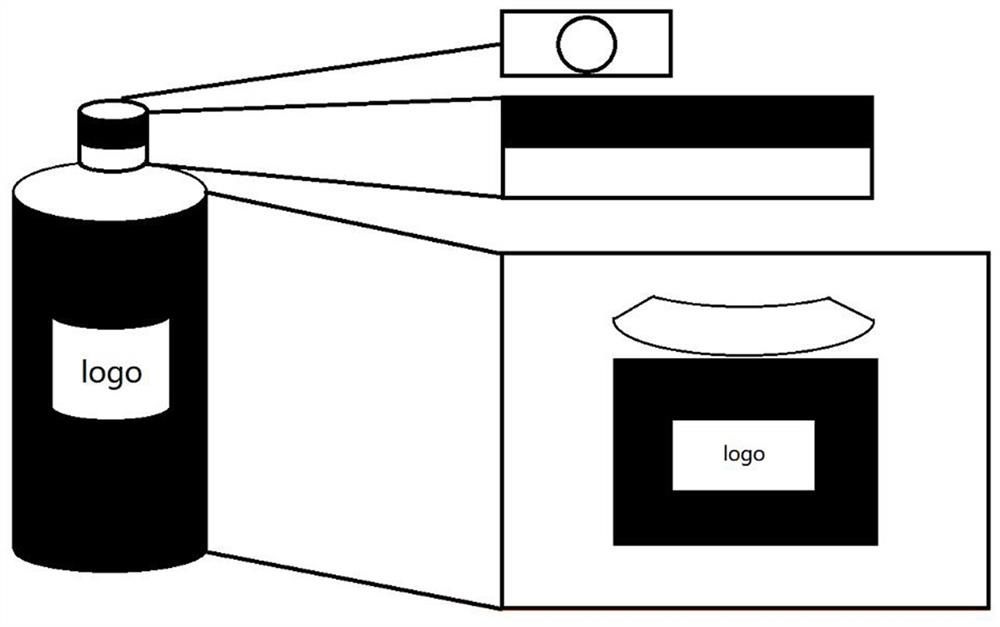

[0078] The wine bottle defects referred to in this application usually include but are not limited to bottle cap defects, label defects, coding defects, bottle body defects, etc.

[0079] In addition, it is also necessary to establish a 3D model of the wine bottle. The establishment of the 3D model of the wine bottle may include the following steps:

[0080] 1) Use Solidworks and other software to create a 1:1 wine bottle 3D model according to the actual size of the wine bottle, and set the model surface to be blank, so as to prepare for the later pasting of surface defect pictures;

[0081] 2) According to the surface size of the bottle cap and body of the wine bottle, design the unfolded dimension drawing of the wine bottle sample; this dimension drawing can be used as the dimension drawing required in step S12 to facilitate the prepro...

Embodiment approach 2

[0152] The applicant found that when the similarity between the second sample representing the 2D wine bottle defect image and the real sample is determined, the second sample can be better evaluated to determine whether it is necessary to optimize the adversarial neural network.

[0153] For this reason, the embodiment of the present application is improved on the basis of the first embodiment, see Figure 4 as shown, Figure 4 The structural diagram of the anti-neural generation network in a deep neural network-based wine bottle defect sample generation method provided for the implementation of the present application, the improvements are as follows:

[0154] The anti-neural generation network also includes a discriminant network structure, which includes a fifth deconvolution kernel, a sixth deconvolution kernel, a seventh deconvolution kernel, and an eighth deconvolution kernel;

[0155] The second feature map and the pre-collected real defect samples used as labels are ...

Embodiment approach 3

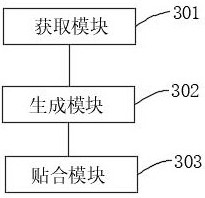

[0167] The embodiment of the present application provides a wine bottle defect sample generation system based on a deep neural network, including:

[0168] The obtaining module 301 is used to obtain a data set of real wine bottle defect pictures, perform preprocessing and expansion operations to obtain a sample set, and the sample set includes training samples; it is also used for:

[0169] Processing includes:

[0170] S11. Using the camera to collect images of several defective wine bottles from different angles or directions, and obtain ,in, is the k-th image data of the i-th wine bottle, and both i and k are positive integers.

[0171] S12. Will The data in the group are registered and cut according to the sample size map of the wine bottle, and the obtained ,in Cut out the top of the wine bottle cap, Cut out the circle around the waist of the wine bottle cap, It is the cutout picture of the front of the wine bottle, It is the cutout diagram of the back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com