Design method of bionic spherical lattice structure for manually setting mechanical property distribution

A technology of lattice structure and design method, which is applied in the fields of informatics, computer material science, instruments, etc., can solve the problems of low flexibility in combination of mechanical properties, lack of cell connection design method, and difficult connection of cell structure, etc., to achieve Improve the overall mechanical properties of the structure, enhance the application value, and enhance the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

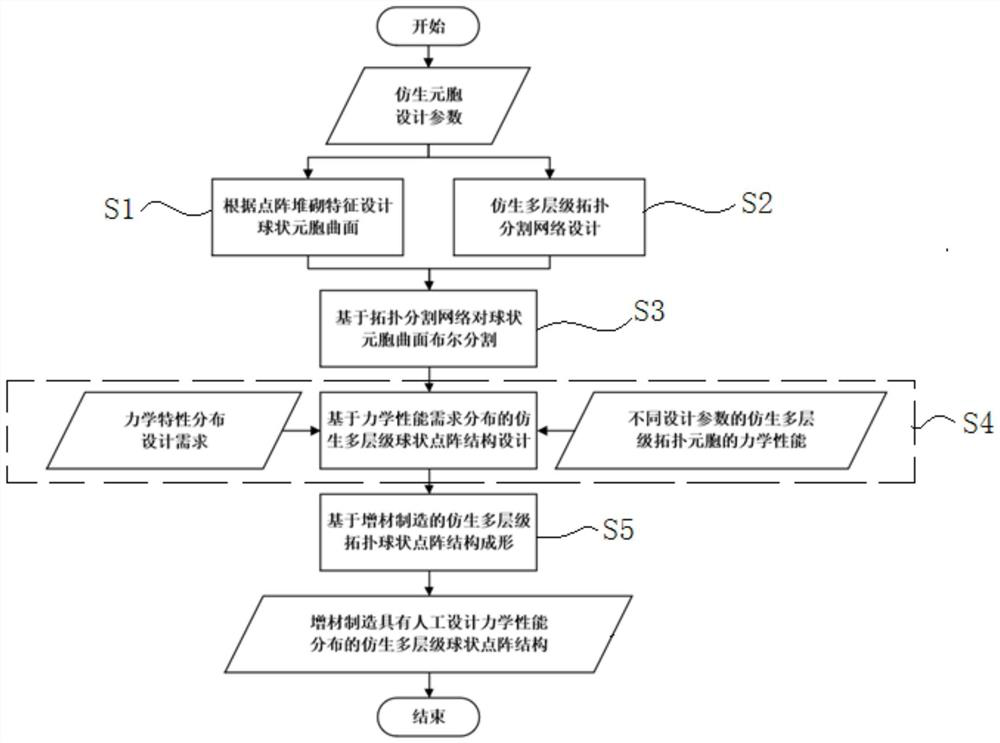

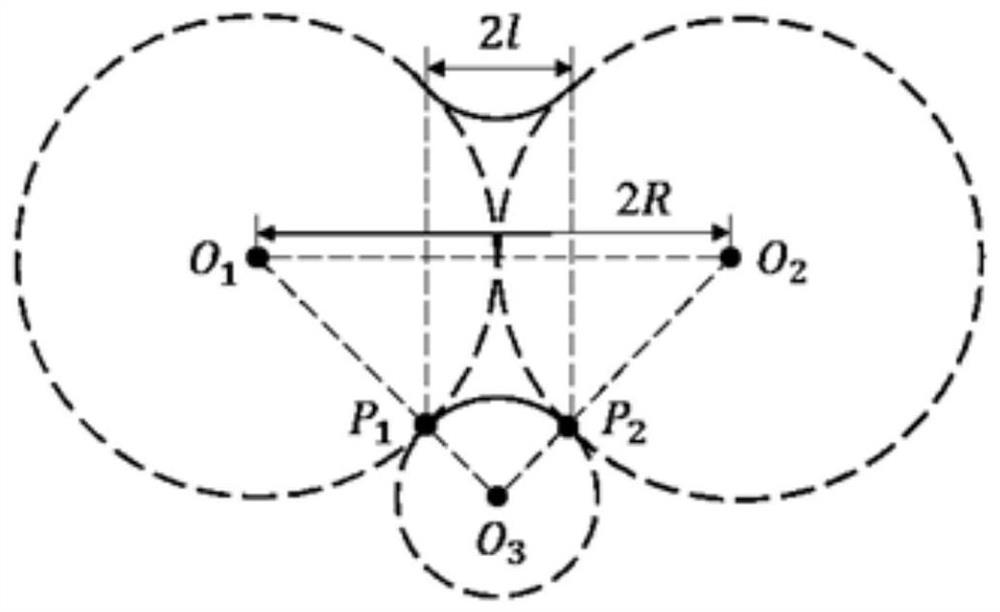

[0040] see figure 1 As shown, the present invention provides a method for designing a bionic spherical lattice structure that manually sets the distribution of mechanical properties, including the following steps: S1, designing a spherical cell surface according to the lattice stacking properties; S2, designing a bionic multi-level topology segmentation network; S3 , Boolean segmentation of spherical cells through topological segmentation network; S4, comparison of bionic multi-level spherical cells based on mechanical property distribution requirements and different design parameters, and realize artificially designed lattice distribution of mechanical properties through performance matching; S5, using additive materials Manufacturing technology shapes and manufactures materials.

[0041] The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap