Steel plate moving device and moving method

A mobile device, steel plate technology, applied in the field of machinery, can solve problems such as low transfer efficiency and worker injury, and achieve the effects of improving transfer efficiency, ensuring stability and safety, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

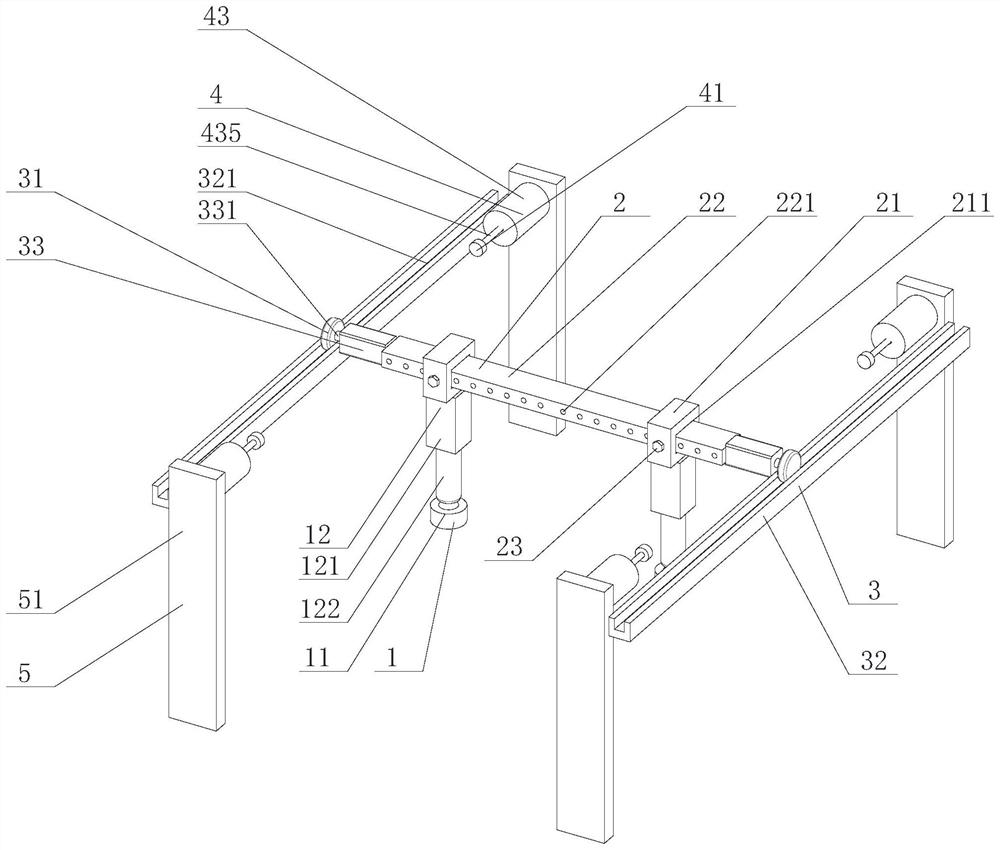

[0062] see Figure 1-Figure 2 , a steel plate moving device of this embodiment is applied to a steel plate truss production line, including:

[0063] Handle mechanism 1, is used for grasping steel plate (not shown in the figure) in vertical direction;

[0064] An adjustment mechanism 2, connected to at least one of the gripper mechanisms 1, for adjusting the position of the at least one gripper mechanism 1;

[0065] a moving mechanism 3, connected to the adjusting mechanism 2, and used to move the handle mechanism 1 in the horizontal direction;

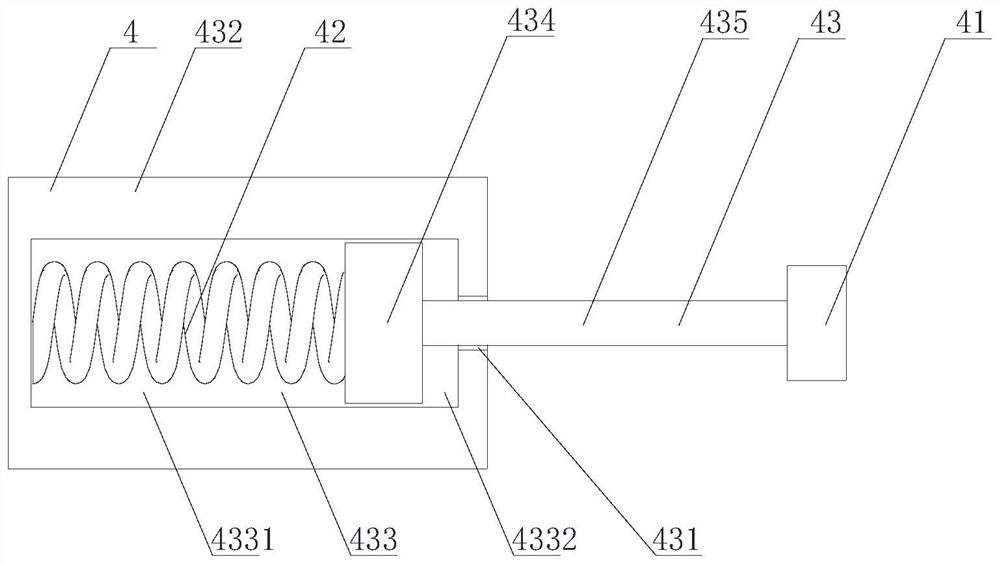

[0066] The buffer mechanism 4 is connected with the moving mechanism 3 and used for buffering the moving mechanism 3 .

[0067] The supporting frame 5 is connected with the buffer mechanism 4 and the moving mechanism 3 and is used for fixing the buffer mechanism 4 and the moving mechanism 3 .

[0068] The working principle of the above-mentioned technical scheme is: arranging the support frame 5 and the moving mechanism 3, so that th...

Embodiment 2

[0102] see Figure 1-Figure 3 , a steel plate moving method of the present embodiment, comprising:

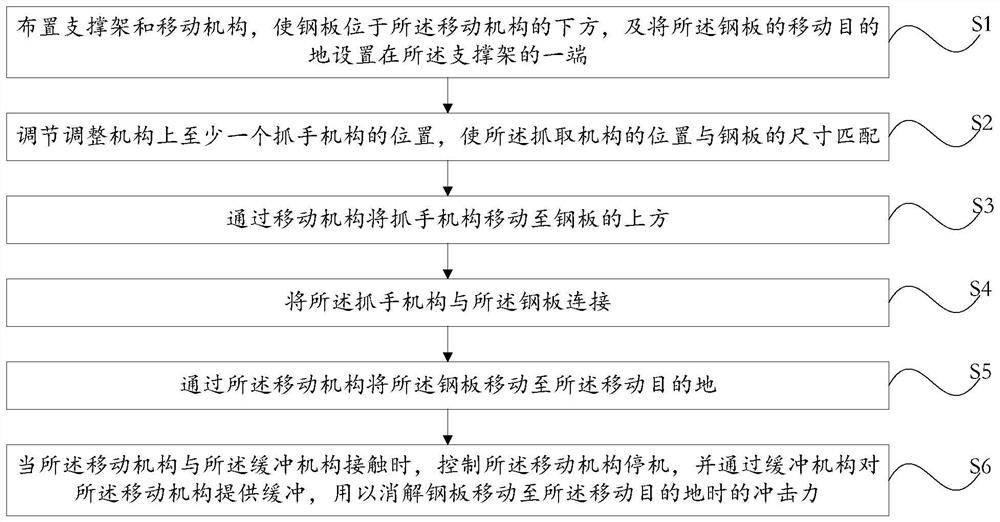

[0103] S1: arranging the support frame 5 and the moving mechanism 3 so that the steel plate is located below the moving mechanism 3, and setting the moving destination of the steel plate at one end of the support frame 5;

[0104] S2: adjusting the position of at least one handle mechanism 1 on the adjustment mechanism 2, so that the position of the handle mechanism 1 matches the size of the steel plate;

[0105] S3: Move the handle mechanism 1 to the top of the steel plate through the moving mechanism 3;

[0106] S4: connecting the gripper mechanism 1 with the steel plate;

[0107] S5: moving the steel plate to the moving destination through the moving mechanism 3;

[0108] S6: When the moving mechanism 3 is in contact with the buffer mechanism 4, control the moving mechanism 3 to stop, and provide buffering for the moving mechanism 3 through the buffer mechanism 4, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com