Tool holder for chip suction device and machine tool including same

一种吸引装置、工具保持的技术,应用在定位装置、机床零件、制造工具等方向,能够解决装置成本增加、难安装工具保持件、不能很好地保证尺寸精度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

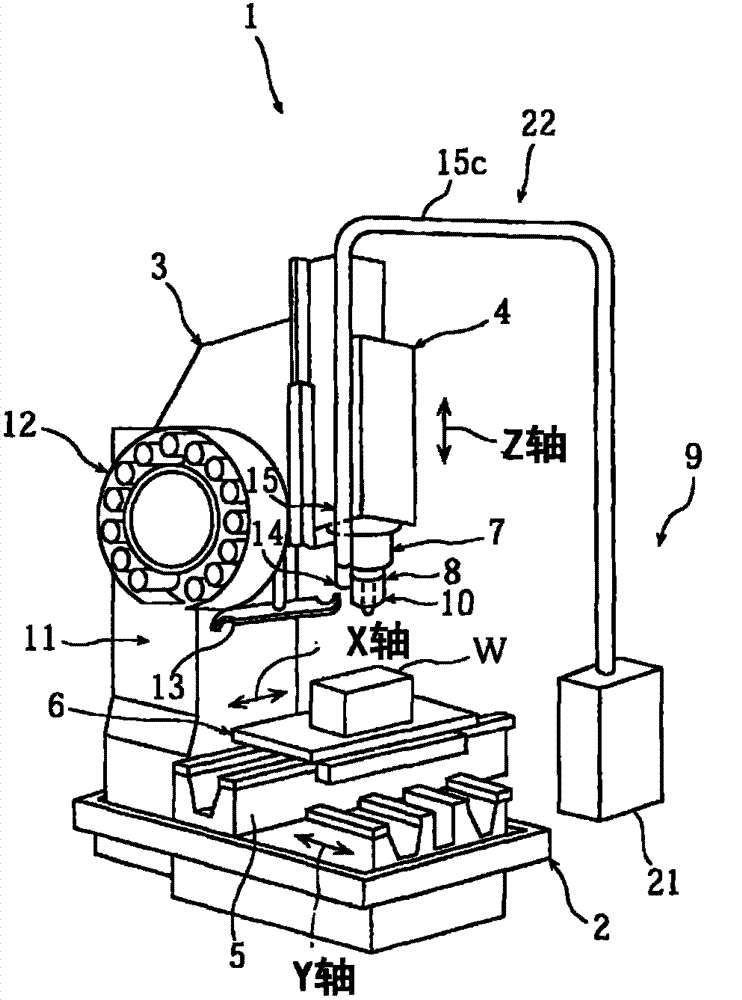

[0042] In the drawings, reference numeral 1 denotes a machine tool provided with the chip suction device tool holder according to the first embodiment of the present invention. This machine tool 1 is provided with a bed 2, a column 3 erected on the rear side when viewed from the front of the bed 2, and a spindle head 4 supported so as to be movable in the vertical direction (Z-axis direction) on the front surface of the column 3. , a base (saddle) 5 supported on the front part of the base 2 so as to be movable in the front-rear direction (Y-axis direction), and a worktable supported on the base 5 so as to be movable in the left-right direction (X-axis direction) (table)6. Furthermore, a tool changing device 11 having a tool magazine 12 , a tool changing arm 13 and the like is provided on a side surface of the column 3 .

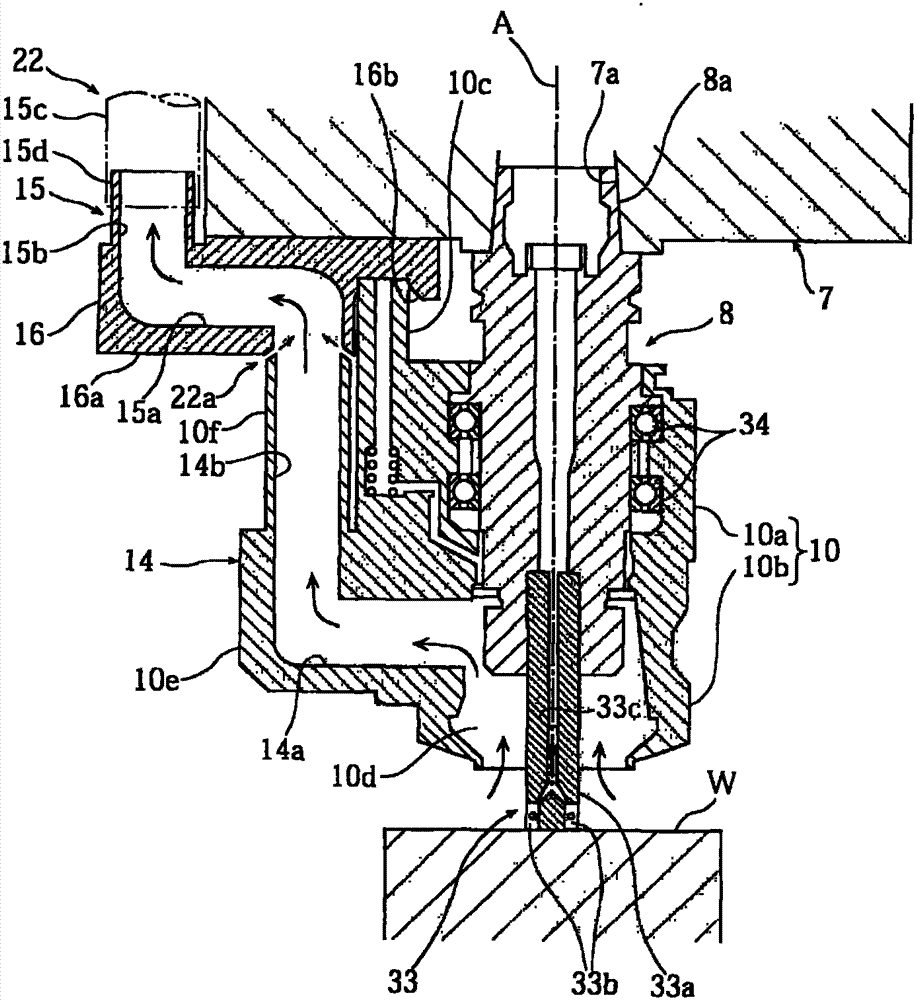

[0043] The spindle 7 is inserted into the spindle head 4 and is rotatably supported. Furthermore, a tool holder 8 is detachably attached to the lower end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com