Preparation machine for water-fertilizer applied to agricultural crop maintenance, and use method thereof

A water fertilizer and compounding machine technology, applied in chemical instruments and methods, mixers, chemical/physical processes, etc., can solve problems such as difficult to drive, high density, high viscosity, and the interaction between fertilizers and horizontal plates cannot be guaranteed, and achieve Optimize the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

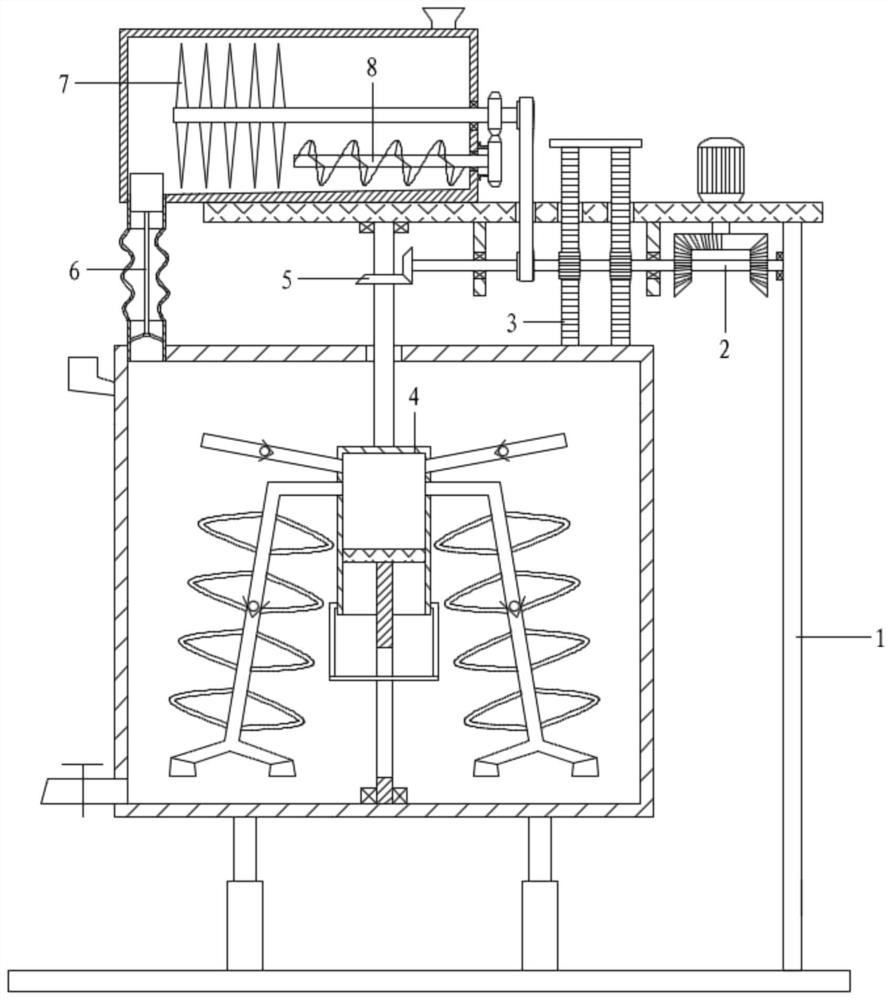

[0065] With reference to the accompanying drawings, a water and fertilizer preparation machine for agricultural crop maintenance includes a frame assembly 1, a drive assembly 2, a lifting assembly 3 and a piston assembly 4;

[0066] The frame assembly 1 includes a base 101, a side plate 102, a top plate 103, a preparation tank 104, a spring telescopic rod 105, a feeding port 106 and a drain pipe 107; A preparation tank 104 is arranged below the top plate 103, and the bottom of the preparation tank 104 is connected to the base 101 through a spring telescopic rod 105; the top left end of the preparation tank 104 has a feeding port 106, and the left bottom is connected with a drain pipe 107, and the drain pipe 107 is equipped with a valve The right part of the top plate 103 is provided with a drive assembly 2, and the right end of the top of the preparation tank 104 is provided with a lifting assembly 3, and the lifting assembly 3 is connected with the drive assembly 2;

Embodiment 2

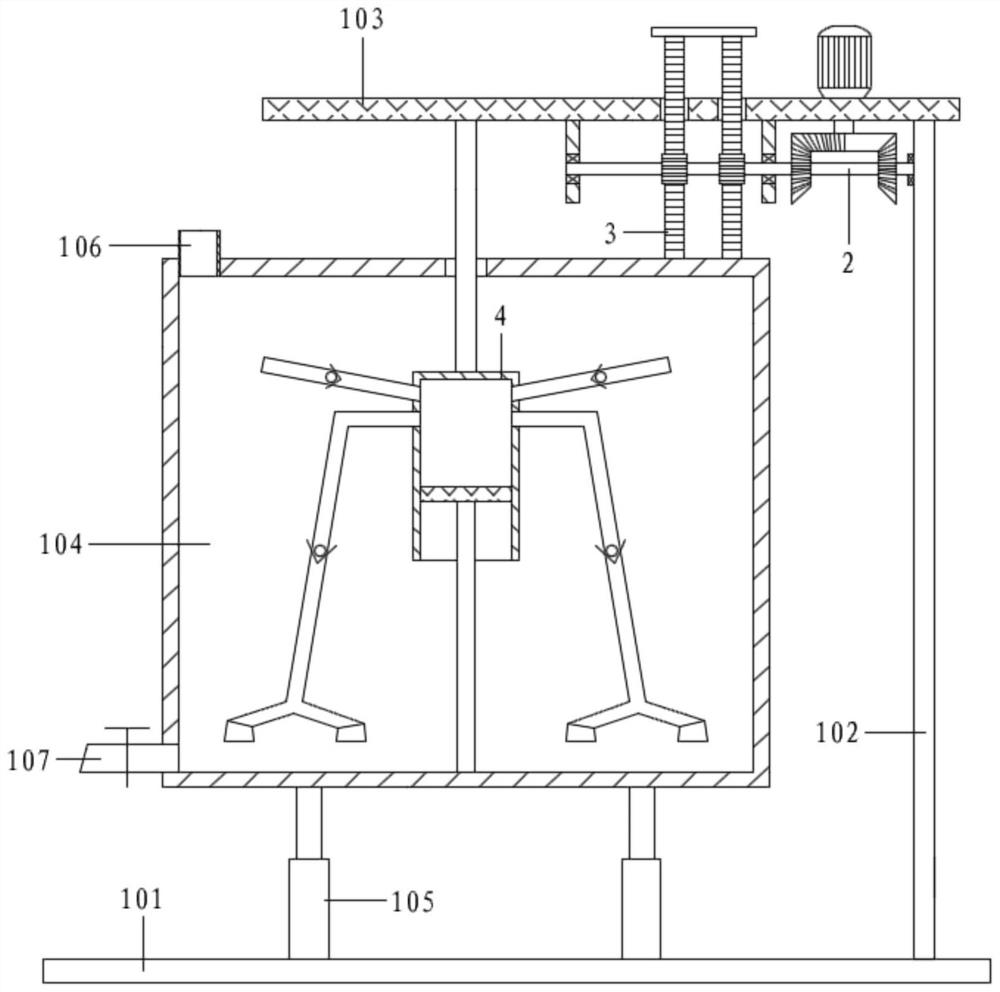

[0068] With reference to the accompanying drawings, a water and fertilizer preparation machine for agricultural crop maintenance includes a frame assembly 1, a drive assembly 2, a lifting assembly 3 and a piston assembly 4;

[0069] The frame assembly 1 includes a base 101, a side plate 102, a top plate 103, a preparation tank 104, a spring telescopic rod 105, a feeding port 106 and a drain pipe 107; A preparation tank 104 is arranged below the top plate 103, and the bottom of the preparation tank 104 is connected to the base 101 through a spring telescopic rod 105; the top left end of the preparation tank 104 has a feeding port 106, and the left bottom is connected with a drain pipe 107, and the drain pipe 107 is equipped with a valve The right part of the top plate 103 is provided with a drive assembly 2, and the right end of the top of the preparation tank 104 is provided with a lifting assembly 3, and the lifting assembly 3 is connected with the drive assembly 2;

[0070] ...

Embodiment 3

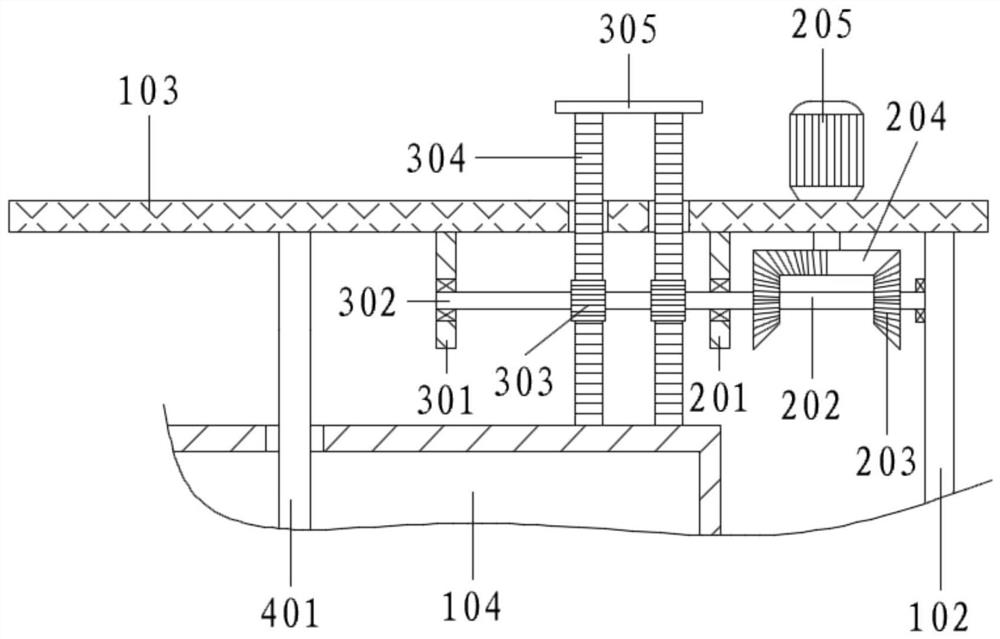

[0085] Embodiment 2 uses the piston assembly 4 to form a circulating flow for material mixing, and there is still room for improvement in efficiency. Therefore, this embodiment 3 is provided with a rotating assembly, so that the piston assembly 4 also has a stirring function.

[0086] This embodiment differs from Embodiment 2 in that the top end of the fixed shaft 401 is rotatably connected to the top plate 103 through a bearing, and the bottom end of the piston rod 404 is rotatably connected to the inner bottom of the preparation tank 104 through a bearing;

[0087] The rotating assembly 5 includes a No. 1 bevel gear 501, a No. 2 bevel gear 502, a fixed rod 503 and a sliding rod 504;

[0088] The left end of the second rotating shaft 302 passes through the second support plate 301 and is fixedly connected with the first bevel gear 501. The fixed shaft 401 is correspondingly fixed with the second bevel gear 502, and the second bevel gear 502 and the first bevel gear 501 are ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com