Cable recovery device with anti-winding mechanism for electromechanical installation engineering

A technology of electromechanical installation engineering and recycling device, applied in the field of electromechanical installation engineering, can solve the problems of recycling efficiency, low cable detection efficiency, winding and other problems, and achieve the effects of improving quality, good recycling effect and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

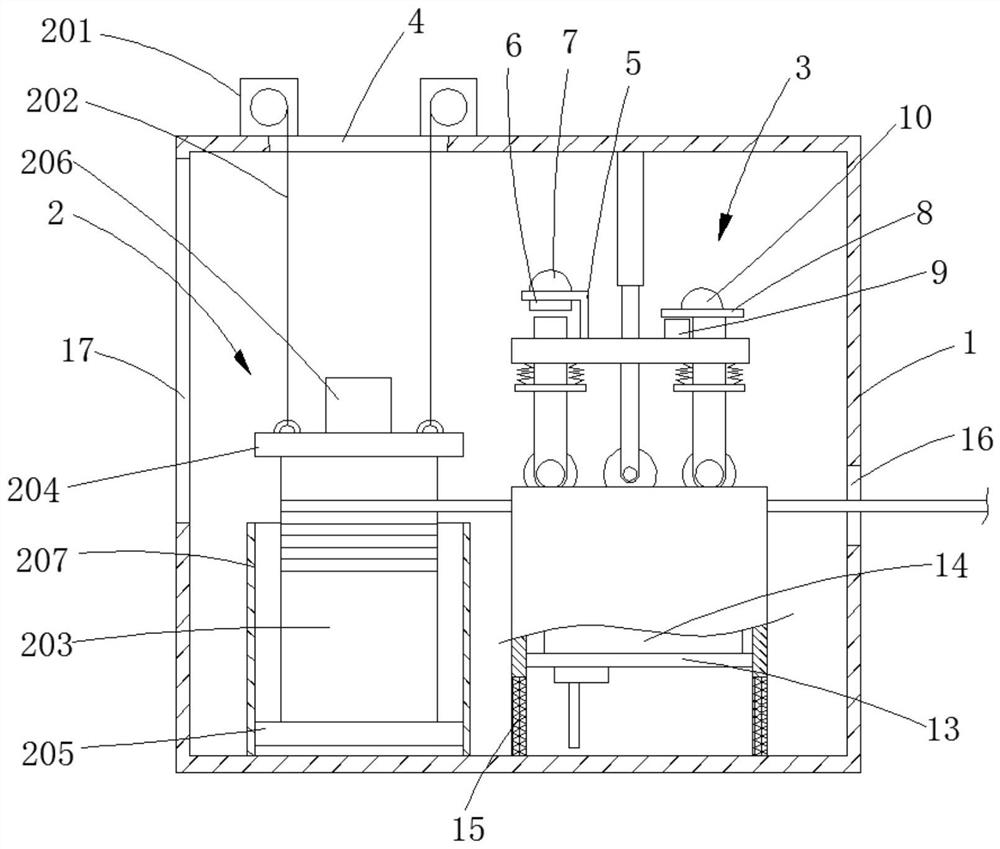

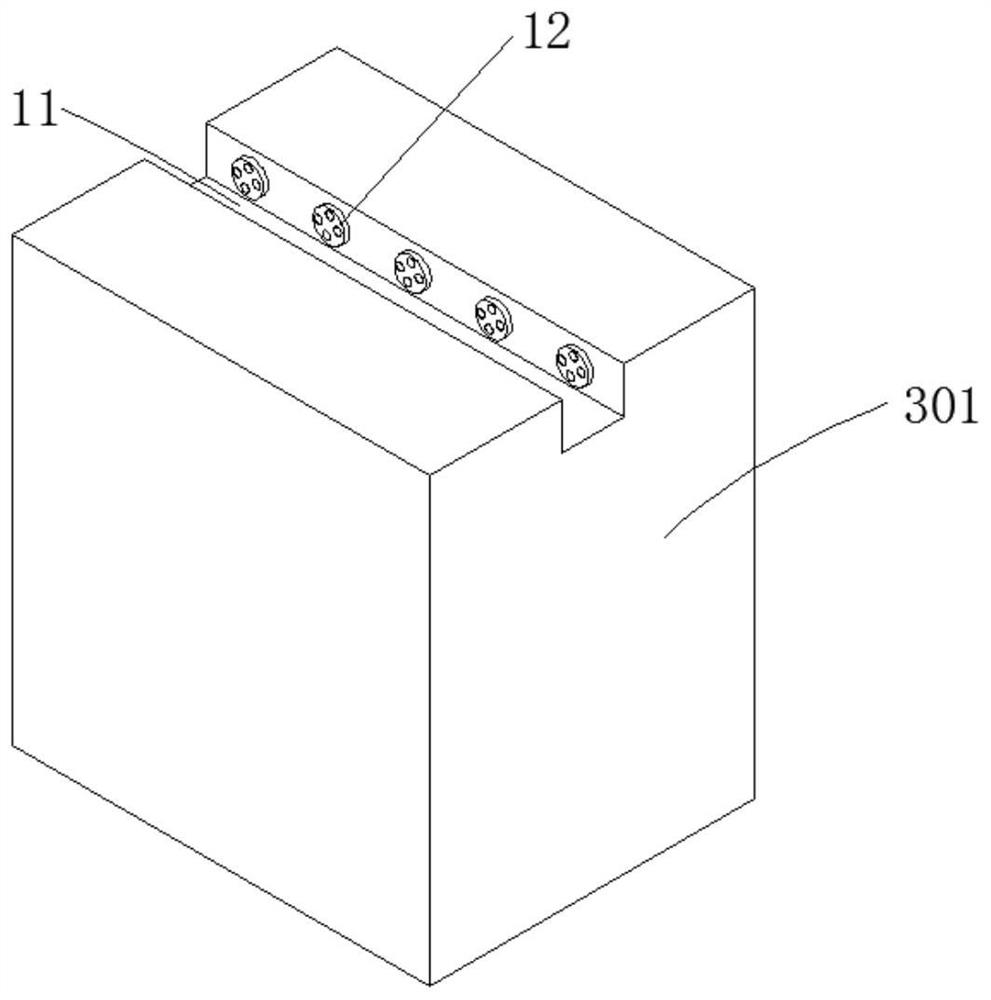

[0028] see Figure 1-5 The present invention provides a technical solution: a cable recovery device with an anti-winding mechanism for electromechanical installation engineering, including a main body box 1, an anti-winding mechanism 2 and a recovery detection mechanism 3, and the anti-winding mechanism 2 includes a retractor 201, Connecting rope 202, winding roller 203, top plate 204, bottom plate 205, motor 206 and limit cylinder 207, the top of main body box 1 is provided with through hole 4, retractor 201 is provided with two groups, and symmetrically arranged in main body box 1 The top is close to the position on both sides of the through hole 4, one end of the connecting rope 202 is fixedly connected to the output end of the retractor 201, the top plate 204 is fixedly connected to the other end of the connecting rope 202, the motor 206 is installed on the top of the top plate 204, and the winding roller 203 is fixedly connected to the output end of the motor 206, the bot...

Embodiment 2

[0035] Compared with embodiment 1, its difference is:

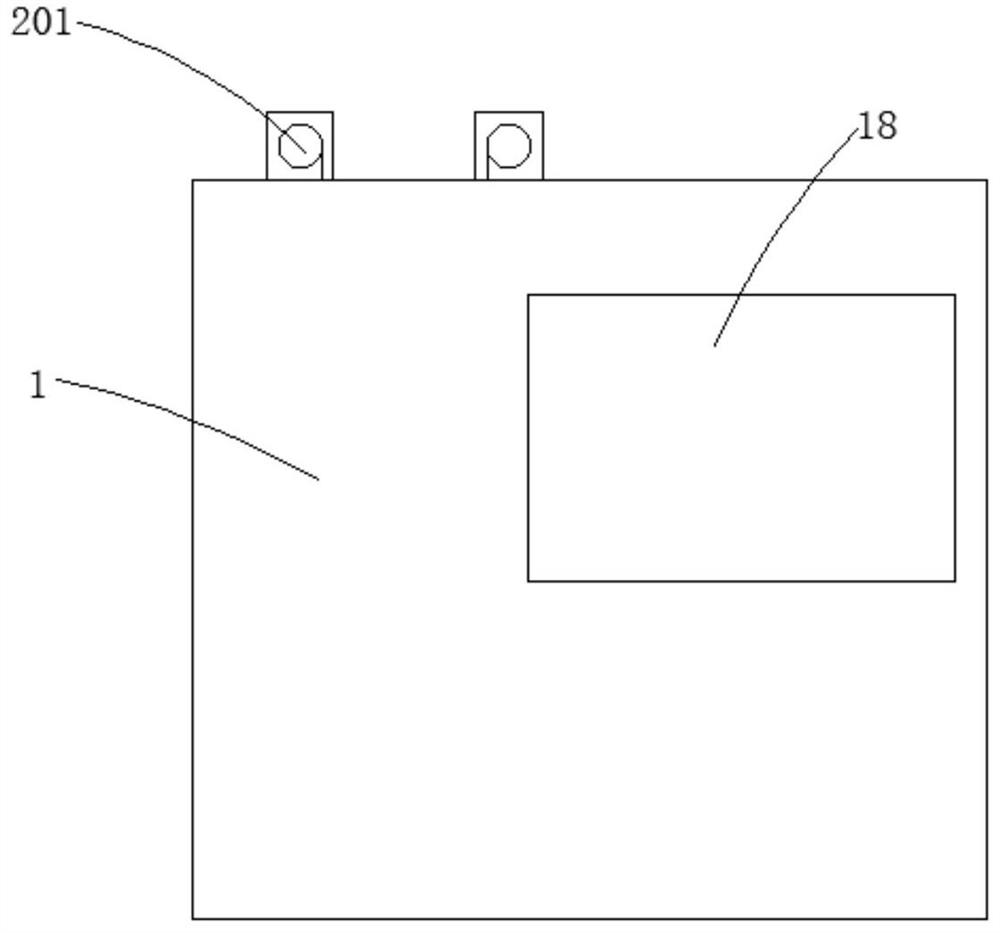

[0036] Wherein, the four corners of the main body box 1 bottom are also provided with moving wheels 19, and the moving wheels 19 are universal wheels with a locking function for use, and the moving wheels 19 provided are more convenient for the movement of the whole device, thereby making the whole device more practical.

Embodiment 3

[0038] Compared with embodiment 1, its difference is:

[0039] Wherein, the front side of the support box 301 is provided with a second telescopic rod 20 fixedly connected to the output end of the second telescopic rod 20 with a lifting frame 21 fixedly connected to the two ends of the lifting frame 21 with a marker pen 22, and the marker pen 22 Located in the same plane as the groove 11, the marker pen 22 provided can accurately trace the position of the defect of the cable, thereby facilitating subsequent processing.

[0040]A specific application of this embodiment is: the device provides electric energy to the electrical components in the device through an external power supply, and controls their opening and closing through a control switch;

[0041] When in use, first extend one end of the cable from the feed port 10, pass through the groove 11, and wind it around the winding roller 203, then adjust the telescopic rod 302 so that the limit wheel 305 descends and just tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com