Plug valve and gas stove

A plug valve and spool technology, applied in the field of stoves, can solve problems such as difficult adjustment, small adjustment range of intermediate firepower, poor user experience, etc., to achieve linear adjustment, increase adjustment range and adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] During the use of the plug valve in the related art, the gas valve stem is in the maximum fire state when it is turned to 90°, and it is in the minimum fire state when it is 210°. The low-fire state occupies a wide adjustment range, and the transition range is small, so accurate adjustment cannot be achieved, thereby affecting the cooking effect.

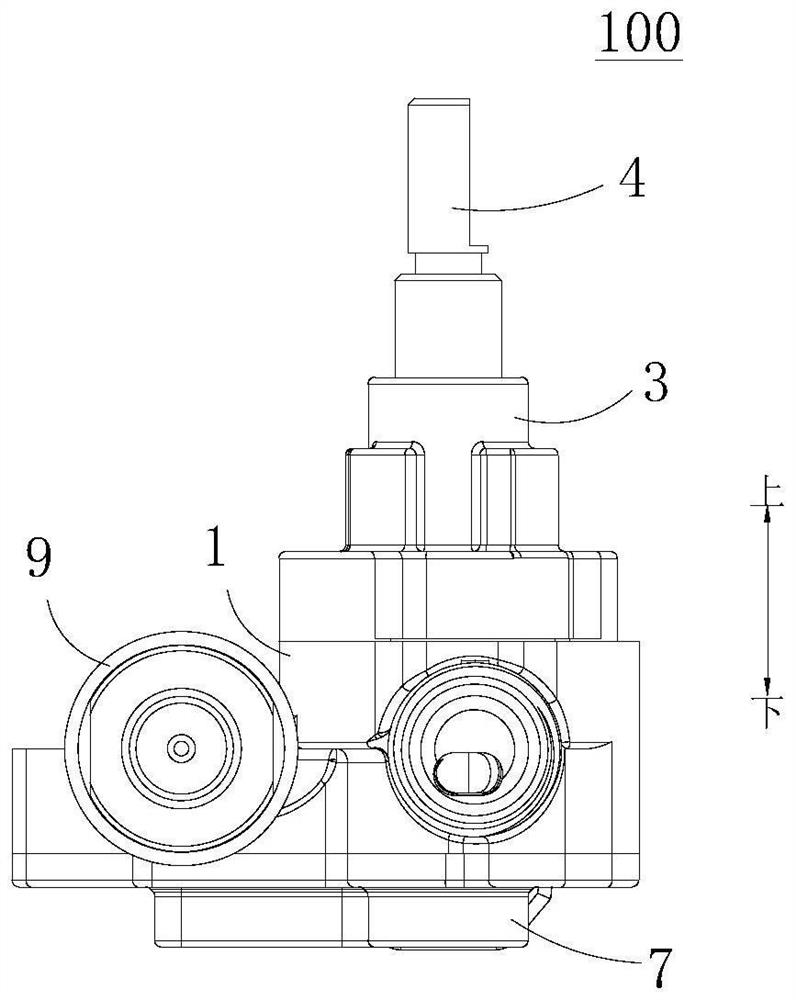

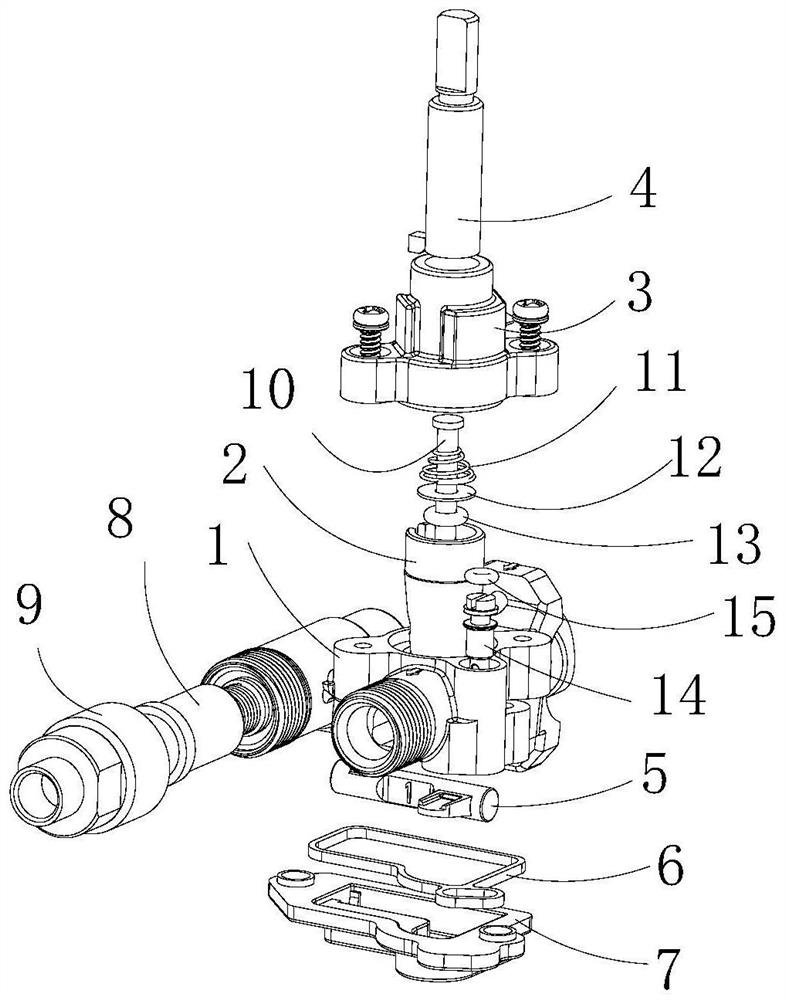

[0042] For this reason, the present invention proposes a cock valve 100, which can improve the flow regulation performance of the gas valve, make the flow change linearly, facilitate the adjustment of firepower, and meet various firepower requirements in the cooking process.

[0043] Embodiments of the present invention are described in detail below, wherein the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions.

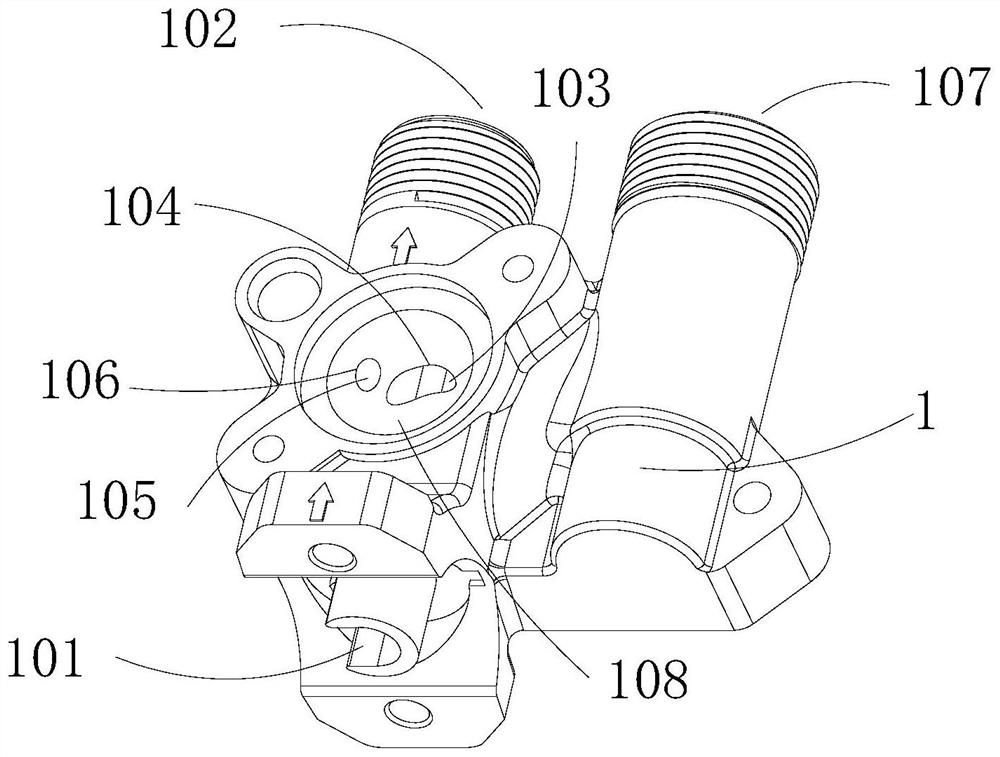

[0044] to combine Figure 1 to Figure 6 and Figure 7 to Figure 18 According to the embodiment of the present invention, the plug valve 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com