An automatic control device for cold water pressure in copper processing

An automatic control device and cold water technology, applied in the field of copper processing equipment, can solve problems such as adjustment errors and fluctuations, linear correlation of water pumps, unfavorable metallographic structure uniformity of copper rods, etc., to achieve accurate adjustment, simplified structure, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

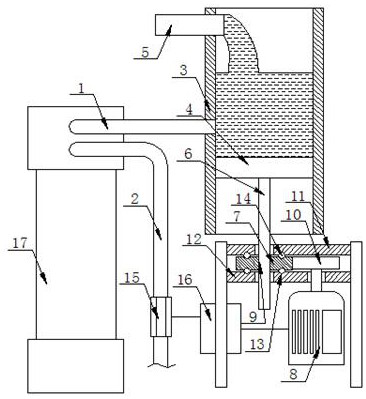

[0015] refer to figure 1 , figure 1 It is a schematic structural diagram of a specific embodiment of the present invention.

[0016] like figure 1 As shown, an automatic control device for cold water water pressure for copper processing includes a cooling water inlet pipe 1, a cooling water outlet pipe 2 and a cooling water storage tank 3, the cooling water inlet pipe 1 is connected to the cooling water storage tank 3; the cooling water The water storage tank 3 is provided with a liquid level adjustment piston 4 and a water storage input pipe 5, and the water storage input pipe 5 is located above the connection between the cooling water inlet pipe 1 and the cooling water storage tank 3. The surface adjustment piston 4 is located below the connection between the cooling water inlet pipe 1 and the cooling water storage tank 3, the bottom of the liquid level adjustment piston 4 is connected to the piston drive connecting rod 6, and the bottom of the piston drive connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com