High-precision quantitative feeding belt weigher

A technology of quantitative feeding and belt scales, which is applied in the direction of weighing, measuring devices, and weighing equipment for continuous material flow. The effect of preventing accumulation and avoiding material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

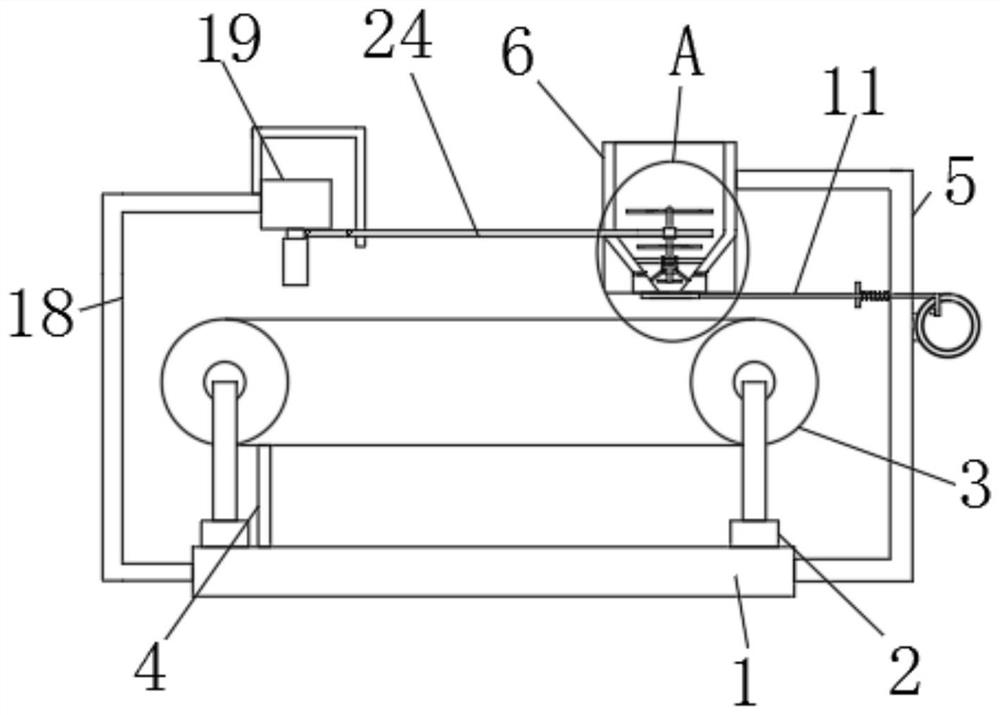

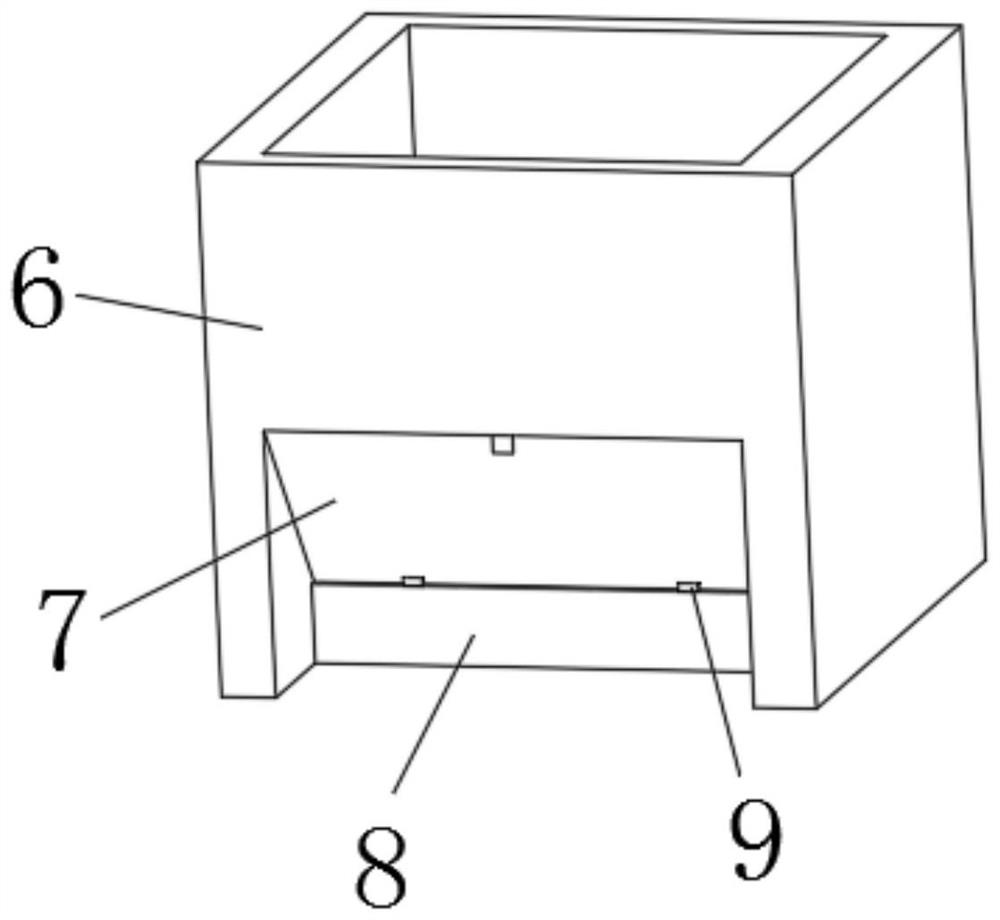

[0039] refer to Figure 1-6 A quantitative feeding belt scale with high precision is shown, including a base 1, four load cells 2 are installed on the top of the base 1, a weighing belt 3 is installed on the top of the four load cells 2, and a weighing belt 3 is installed on the top of the base 1 A scraper 4 is installed, and the scraper 4 is installed in cooperation with the weighing belt 3. A U-shaped mounting rod 5 is installed on the side of the base 1, and a feeding frame 6 is installed on the top of the U-shaped mounting rod 5. The side of the feeding frame 6 There are two through-holes on the upper part, the inner walls of the two through-holes are equipped with a material guide slant plate 7, and the bottoms of the two material guide slant plates 7 are slidingly installed with a material guide trapezoidal plate 8, and the side of the U-shaped installation rod 5 An intermittent feeding mechanism is installed at the top, which corresponds to the position of the guide tra...

Embodiment 2

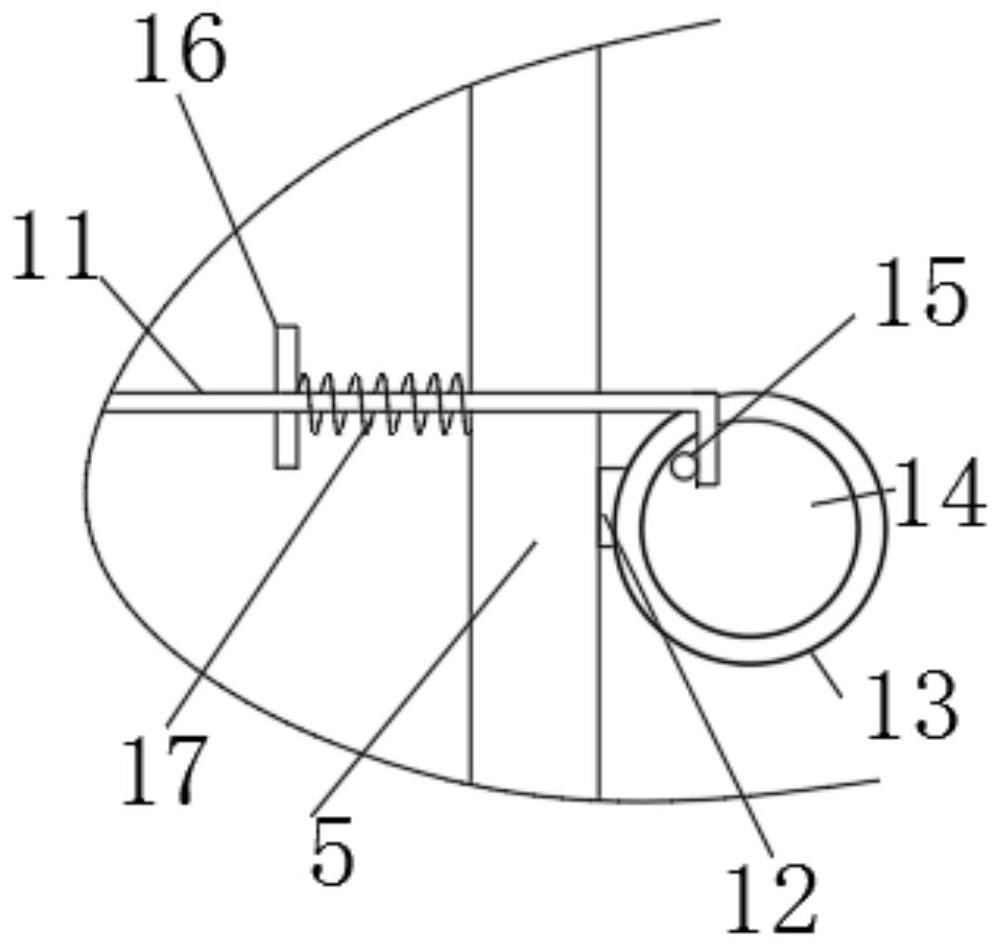

[0042] Based on above-mentioned embodiment 1, intermittent feeding mechanism comprises the connecting column 12 that is installed in U-shaped mounting bar 5 side parts, and the end of connecting column 12 is equipped with driving motor 13, and the output end of driving motor 13 is equipped with driving plate 14, drives An extruding head 15 is installed eccentrically on the side of the disk 14, and a sliding hole is opened on the side of the U-shaped mounting rod 5, and an L-shaped extruding rod 11 is slidably installed in the sliding hole, and the L-shaped extruding rod 11 and the extruding head 15 The sides of the L-shaped extruding rod 11 are connected with an elastic unit, and the end of the L-shaped extruding rod 11 away from the drive motor 13 is equipped with a blocking plate 10, which is connected to the two guide trapezoidal plates 8. corresponding to the location. Start the drive motor 13, the output end of the drive motor 13 rotates to drive the drive plate 14 to rot...

Embodiment 3

[0044] Based on the above-mentioned embodiment 1 or 2, the elastic unit includes a limit plate 16 fixedly sleeved on the L-shaped extruding rod 11, and a limit spring 17 is sleeved on the L-shaped extruding rod 11, and one end of the limit spring 17 is connected to the limit plate. The side of the position plate 16 is connected, and the other end of the limit plate 16 is connected with the side of the U-shaped mounting rod 5 . The movement of the L-shaped extruding rod 11 drives the limit plate 16 to move, and the movement of the limit plate 16 causes the limit spring 17 to deform, and the force of the limit spring 17 facilitates the recovery of the limit plate 16 to its original shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com