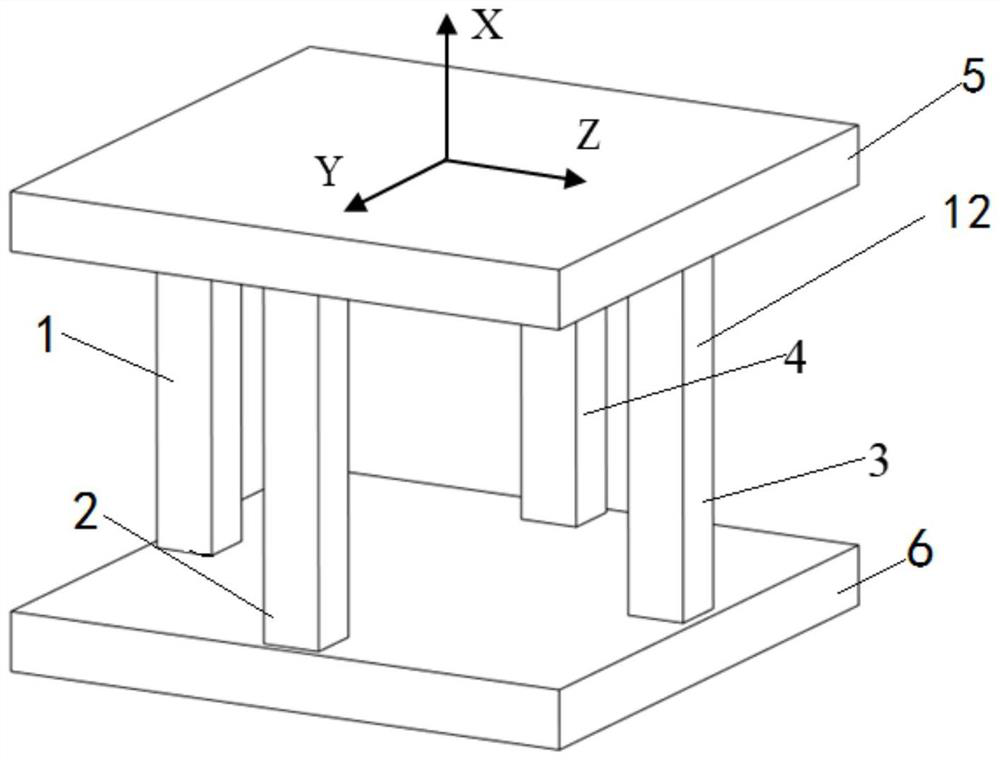

Six-dimensional force measuring platform and decoupling method thereof

A measurement platform and six-dimensional force technology, applied in the field of six-dimensional force measurement platform and its decoupling, can solve the problem of low measurement accuracy, achieve high measurement accuracy, good followability and consistency, no assembly stress and connection gap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

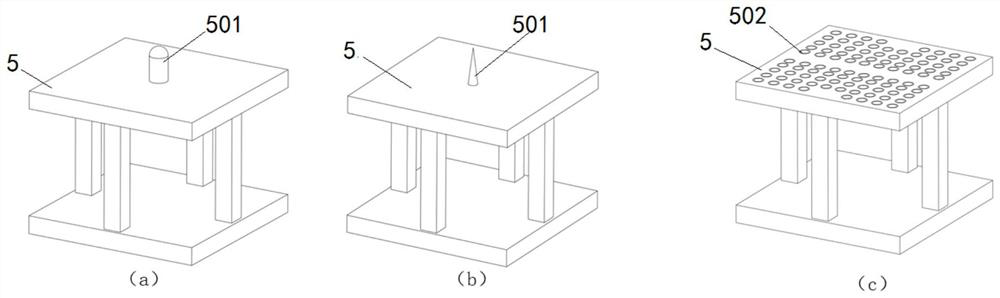

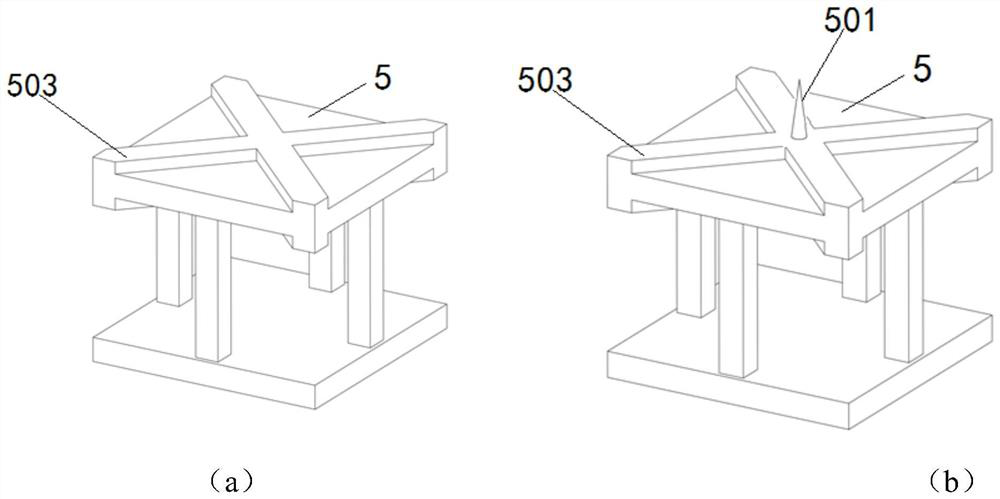

Embodiment 1

[0084] As one of the preferred solutions, one of the three-dimensional force sensors is a polygonal structure, because the polygonal structure has the characteristics of good stability and symmetrical force, which is beneficial to realize the physical decoupling of the multi-dimensional force sensor. In this embodiment, two regular octagonal ring structures 1221 perpendicular to each other are used as the elastic structure of the three-dimensional force sensor, which is defined as a double octagonal elastic structure 122, and are arranged symmetrically at multiple positions of the double octagonal elastic structure 122. A semiconductor resistance strain gauge 13 is combined into three Wheatstone full-bridge circuits to realize the decoupling measurement of three-dimensional force, and the specific introduction is as follows. see Figure 5 (a) and Figure 6 (a), the XY plane and the XZ plane are two central planes of the double octagon elastic structure 122 respectively.

[0...

Embodiment 2

[0098] As one of the preferred solutions, one of the three-dimensional force sensors is a beam structure, which can be a straight beam structure or a variable cross-section beam 121, but its core is to arrange semiconductor resistance strain gauges 13 on the beam structure and combine them into a Decoupling 3 Wheatstone bridges measuring three-dimensional force components.

[0099] Specifically, such as Figure 9 As shown in (a), the middle part of the six-dimensional force measurement platform based on the variable cross-section beam 121 is four variable cross-section, straight beam-type three-dimensional force sensors, and the structure of each three-dimensional force sensor is as follows Figure 9 (b) shown. The variable cross-section beam 121 is divided into upper and lower two short and thick outer quadrangular prisms 1211 and a middle long and thin middle quadrangular prism 1212, the middle quadrangular prism 1212 is arranged between the two outer end quadrangular prism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com