Welding power supply system

A welding power source and welding system technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of shape stability and arc depletion suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

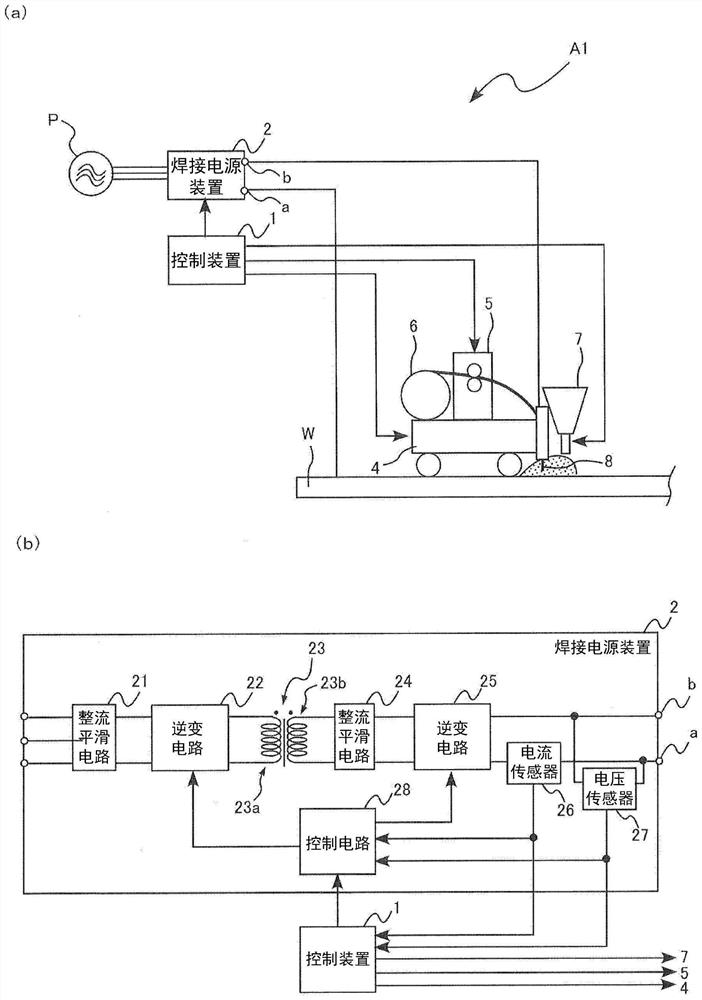

[0024] figure 1 It is a figure for demonstrating the welding system concerning 1st Embodiment. (a) of the figure is a block diagram showing the overall configuration of the welding system. (b) of this figure is a block diagram which shows the internal structure of a welding power supply apparatus.

[0025] Welding system A1 is a welding system for performing submerged arc welding. like figure 1 As shown in (a), the welding system A1 includes a control device 1 , a welding power supply device 2 , a carriage 4 , a wire feeding device 5 , a welding pad 6 , a spreading device 7 , and an electrode 8 . The welding system A1 spreads the granular flux stored in the stocker of the spreading device 7 while moving the trolley 4 along the welding line of the workpiece W, and feeds the welding wire into the welding wire feeding device 5 . in flux. The welding wire is supplied from the bonding pad 6 . The welding power supply device 2 converts AC power supplied from a commercial power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com