Ceramic clay raw material pretreatment equipment and pretreatment process thereof

A pretreatment, clay technology, applied in clay processing equipment, clay preparation devices, chemical instruments and methods, etc., can solve the problems of uneven clay quality, unclean removal of iron blocks, insufficient crushing of clay blocks, etc., to reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

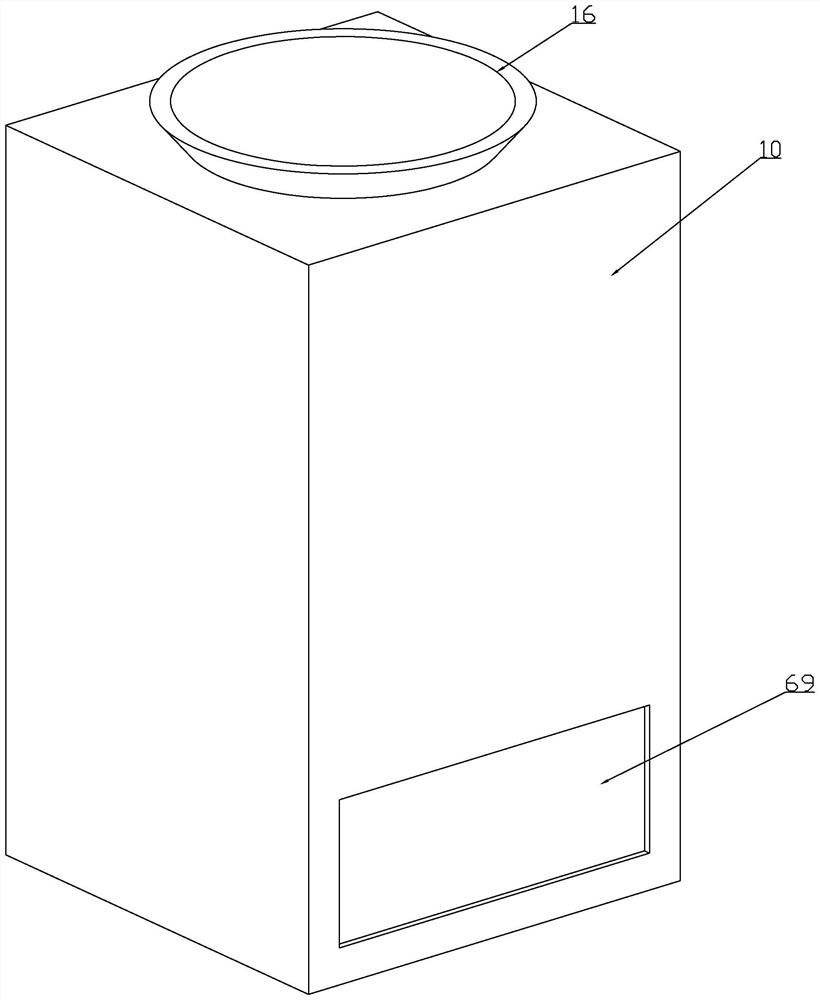

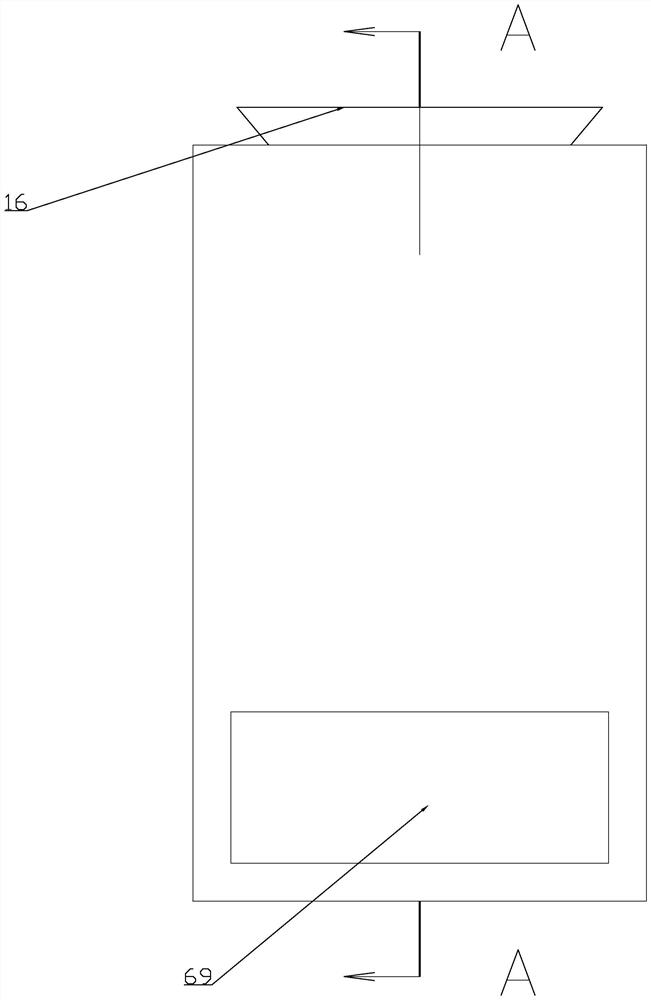

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

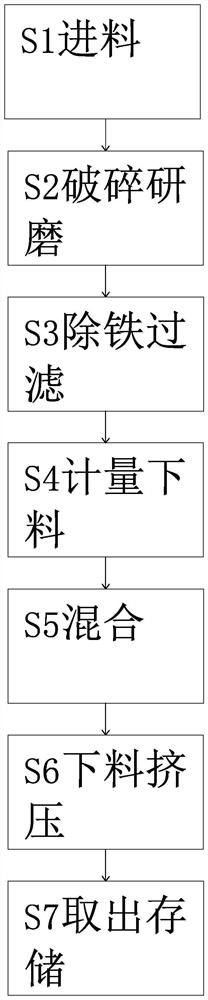

[0040] combine Figure 1-10 , a vitrified clay raw material pretreatment equipment and pretreatment process thereof, comprising the following steps:

[0041] S1: feeding, putting the clay block into the processing box through the feed funnel, controlling the amount of clay block blanking;

[0042] S2: crushing and grinding, crushing the clay block, picking it into the grinding chamber for grinding after crushing;

[0043] S3: remove iron and filter, rotate and absorb the iron in the ground clay, and then filter and discharge the clay;

[0044] S4: Metering and blanking, the clay falls evenly, and then blanks after reaching a certain weight of clay;

[0045]S5: mixing, adding an appropriate amount of water into the clay,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com