Pickup truck hand brake mounting structure

An installation structure and handbrake technology, which is applied in the field of auto parts, can solve the problems of occupying the modeling space of the sub-dashboard, the low versatility of the handbrake mounting bracket, and the difficulty in molding the sub-dashboard, so as to save installation space and facilitate platformization , The effect of improving the stability of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

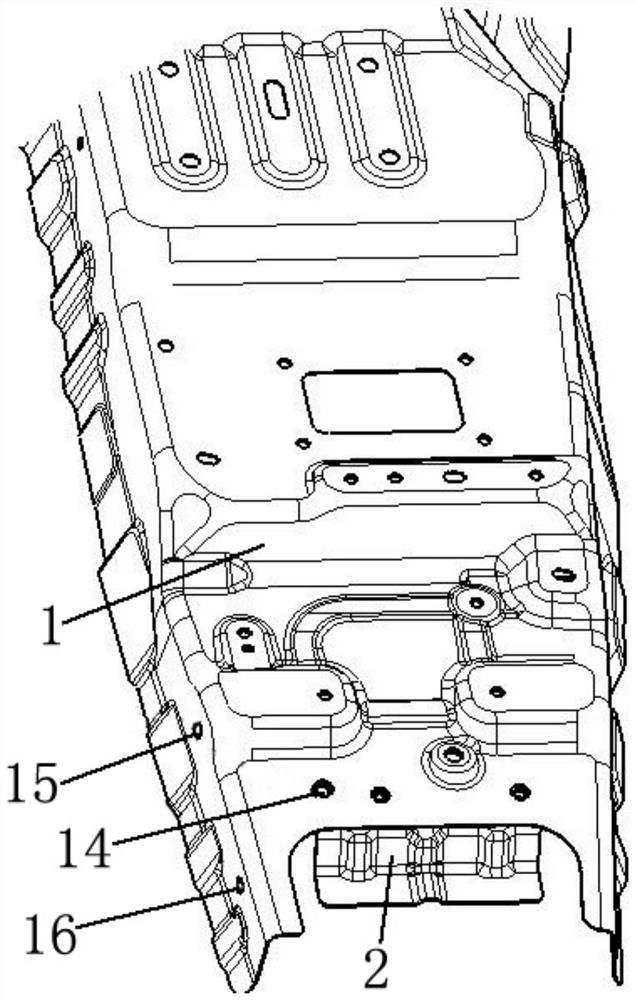

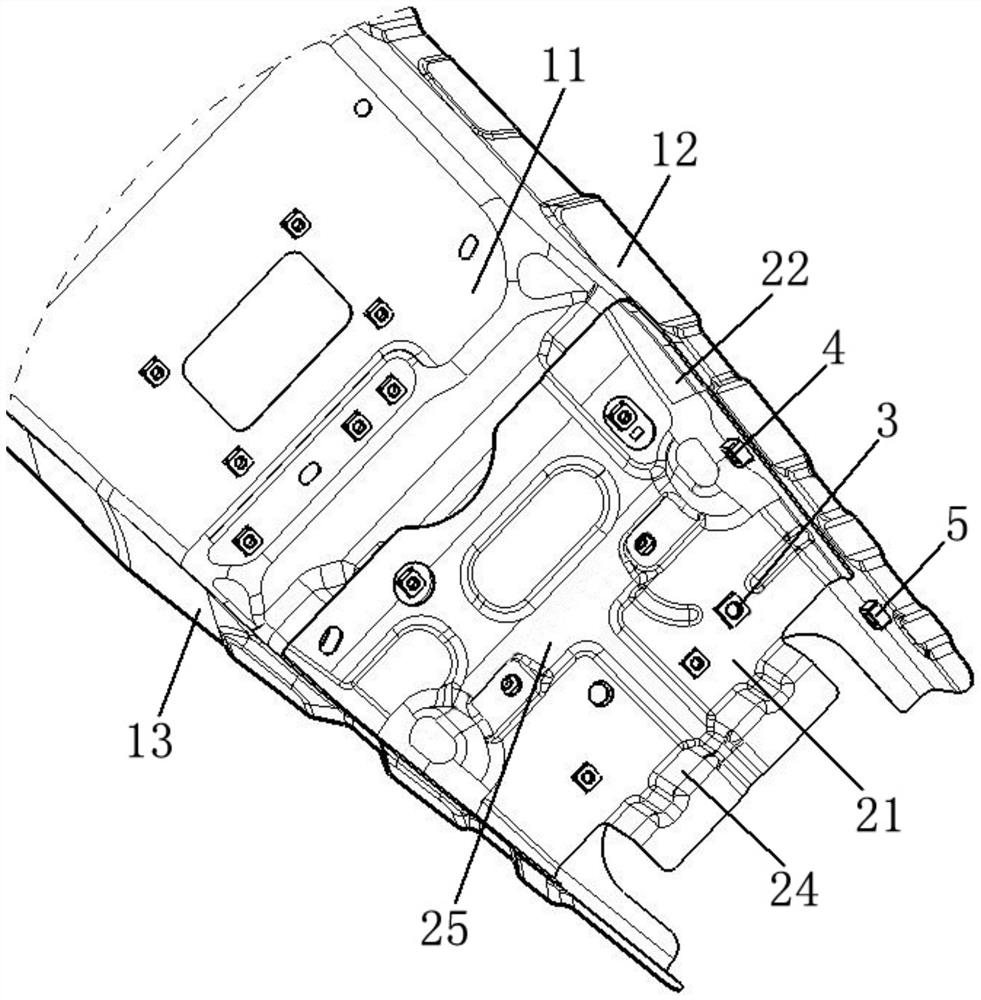

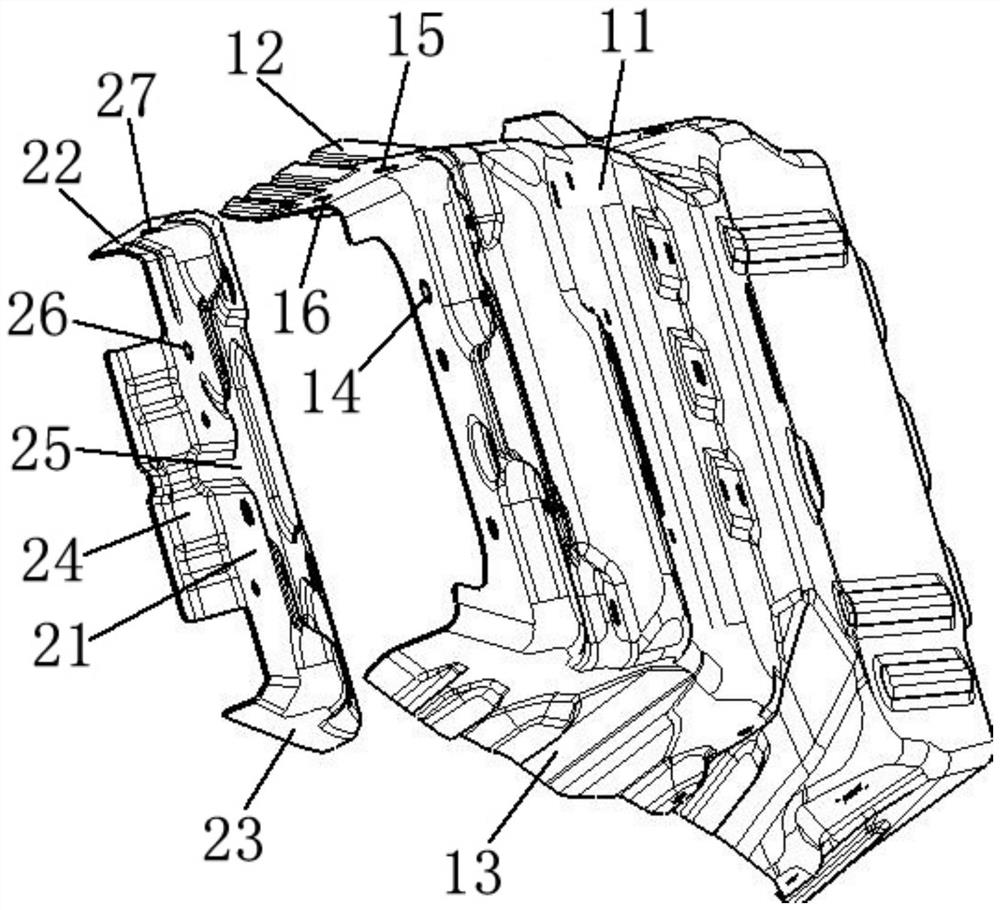

[0021] Such as Figure 1 to Figure 4 A pick-up handbrake installation structure shown includes a front section 1 of a middle channel with an n-shaped cross section. A left side wall 12 and a first right side wall 13 bent downward from the right side edge of the first upper side wall 11, a plurality of handbrake installation holes are arranged on the front section 1 of the middle channel, and a plurality of handbrake installation holes form a plurality of The handbrake installation points and a plurality of handbrake installation holes are respectively arranged at the rear of the first left side wall 12 and the rear of the first upper side wall 11 .

[0022] Adopt above-mentioned pick-up handbrake installation structure, on the first aspect, the handbrake installation hole that is arranged on the rear portion of the first left side wall 12 is fastened and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com