Undercarriage mounting vehicle

A landing gear and installation vehicle technology, applied in lifting gear, hoisting device, aircraft assembly, etc., can solve problems such as unsatisfactory use requirements, hidden safety hazards, and high physical energy consumption, so as to reduce operational safety risks, improve safety, and alleviate The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

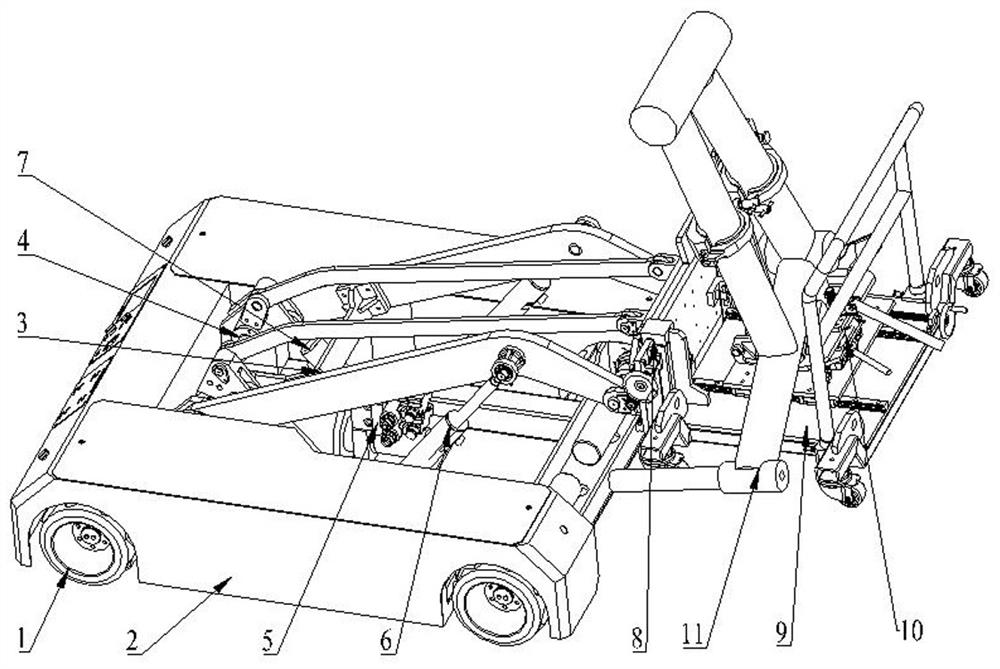

[0015] see figure 1 A landing gear installation vehicle, comprising a mecanum wheel traveling mechanism 1, a vehicle frame 2, a parallel four-bar linkage lifting mechanism 3, a connecting pin 4, a hydraulic pump 5, a lifting adjustment cylinder 6, a pitch adjustment cylinder 7, Tooling trolley hanging plate 8, tooling trolley 9, fine-tuning mechanism 10 and landing gear 11, wherein, the bottom of the vehicle frame 2 is provided with four sets of mecanum wheel running mechanism 1, and the use of mecanum wheels makes the vehicle have Omnidirectional movement function, that is: forward and backward movement, left and right movement and in-situ steering movement, the front end of the frame 2 is provided with a parallel four-bar linkage lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com