Novel glass lining firing furnace

A glass-lined and firing furnace technology, applied in the field of new glass-lined firing furnaces, can solve the problems of waste of heat resources, time-consuming and laborious, environmental pollution, etc., and achieve the effects of ensuring safety, reducing pollution and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

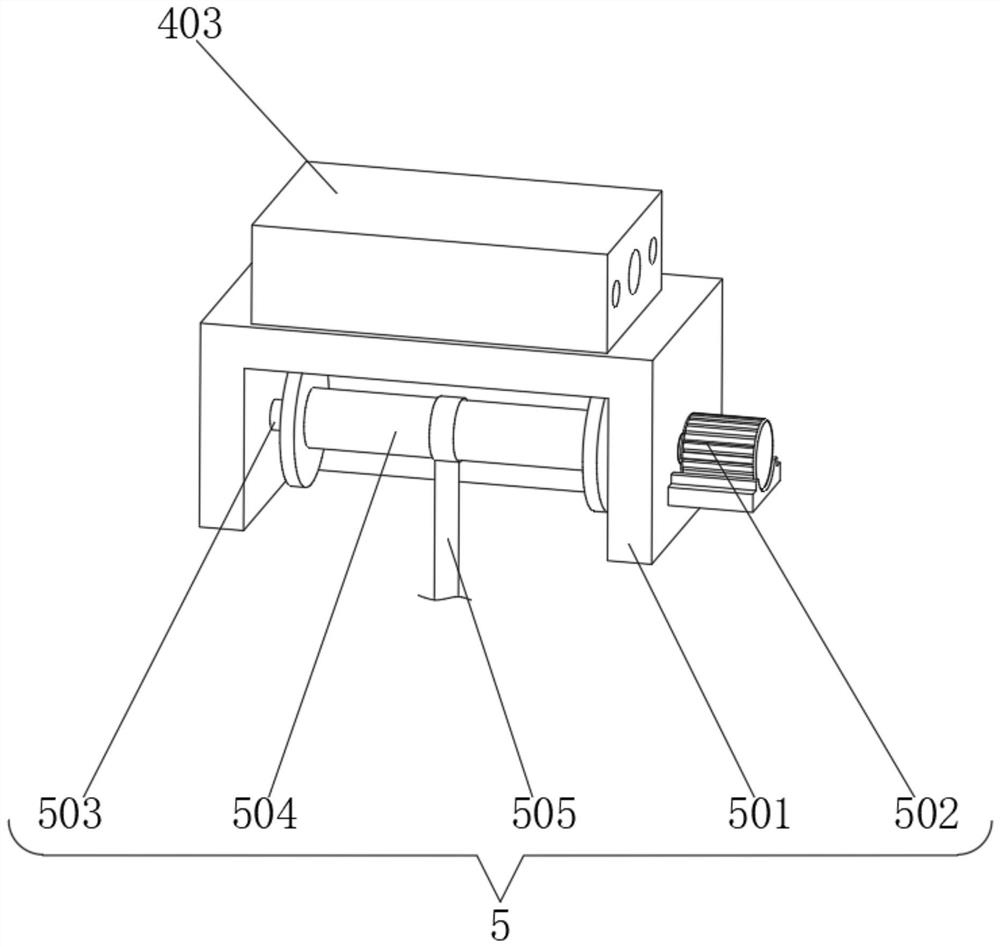

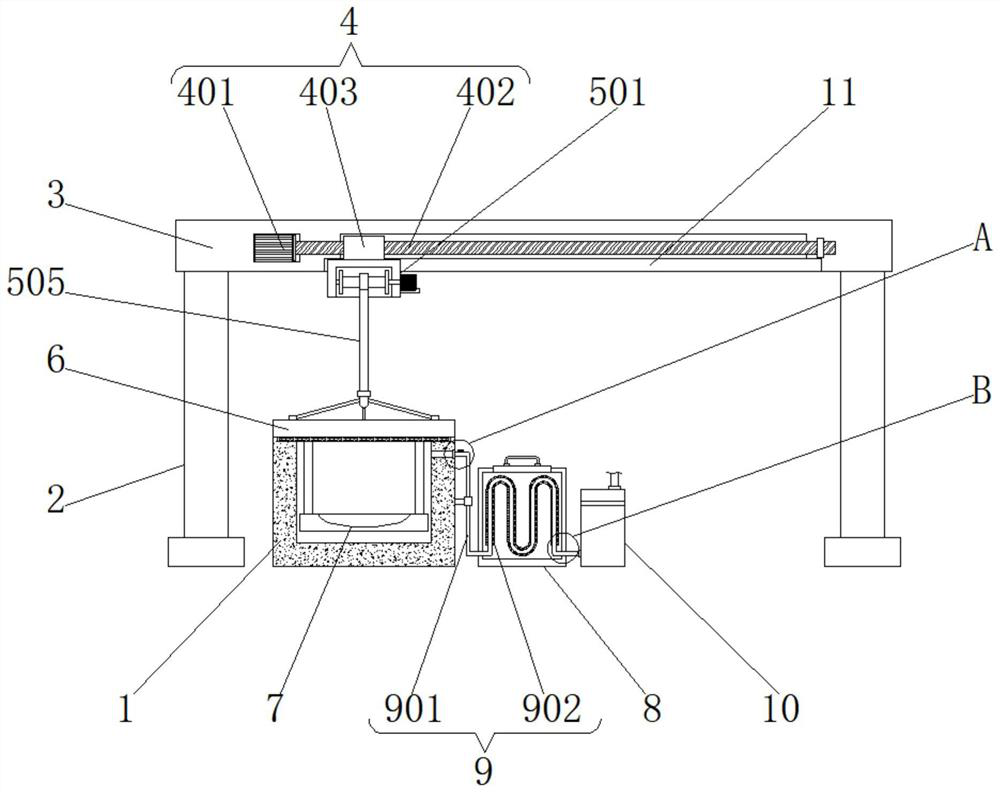

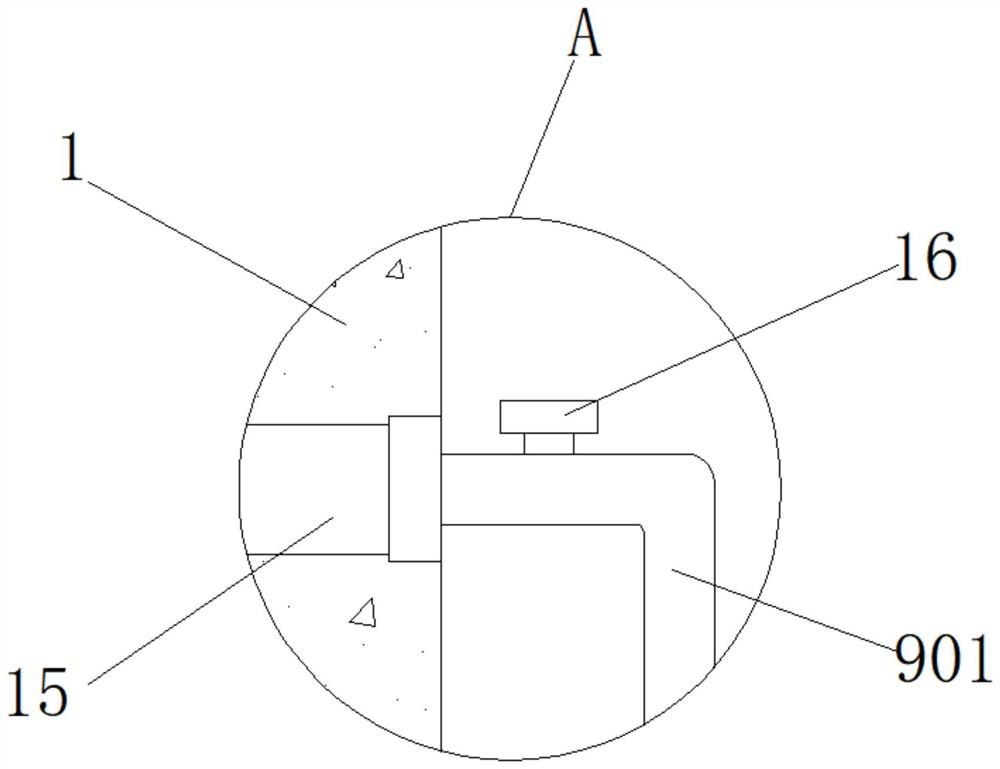

[0029] see Figure 1-5 , a new type of glass-lined firing furnace, including a furnace body 1, the left and right sides of the outside of the furnace body 1 are provided with support columns 2, the tops of the two support columns 2 are fixedly installed with a top plate 3, and a moving mechanism is installed inside the top plate 3 4. The bottom end of the moving mechanism 4 is connected to the hoisting mechanism 5 through transmission. A water tank 8 is arranged on the right outside of the furnace body 1 , and a recovery assembly 9 is arranged inside the water tank 8 .

[0030] Specifically, the moving mechanism 4 includes a servo motor 401, the servo motor 401 is fixedly installed at the left end of the top plate 3, the output end of the servo motor 401 is connected to a screw rod 402 through a coupling transmission, and the outer surface of the screw rod 402 is slidably connected to a The slider 403 starts the servo motor 401, the servo motor 401 can drive the screw rod 402 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com