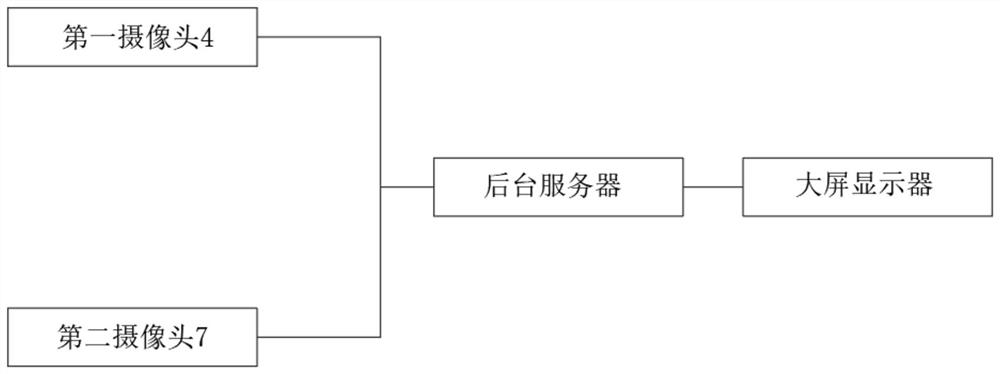

Power machine room monitoring system

A monitoring system and computer room technology, which is applied in the parts, televisions, electrical components and other directions of the TV system, can solve the problems of inability to collect facial information, monitor dead corners, and difficult security monitoring in the computer room, so as to avoid adverse effects of monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to an embodiment of the present invention,

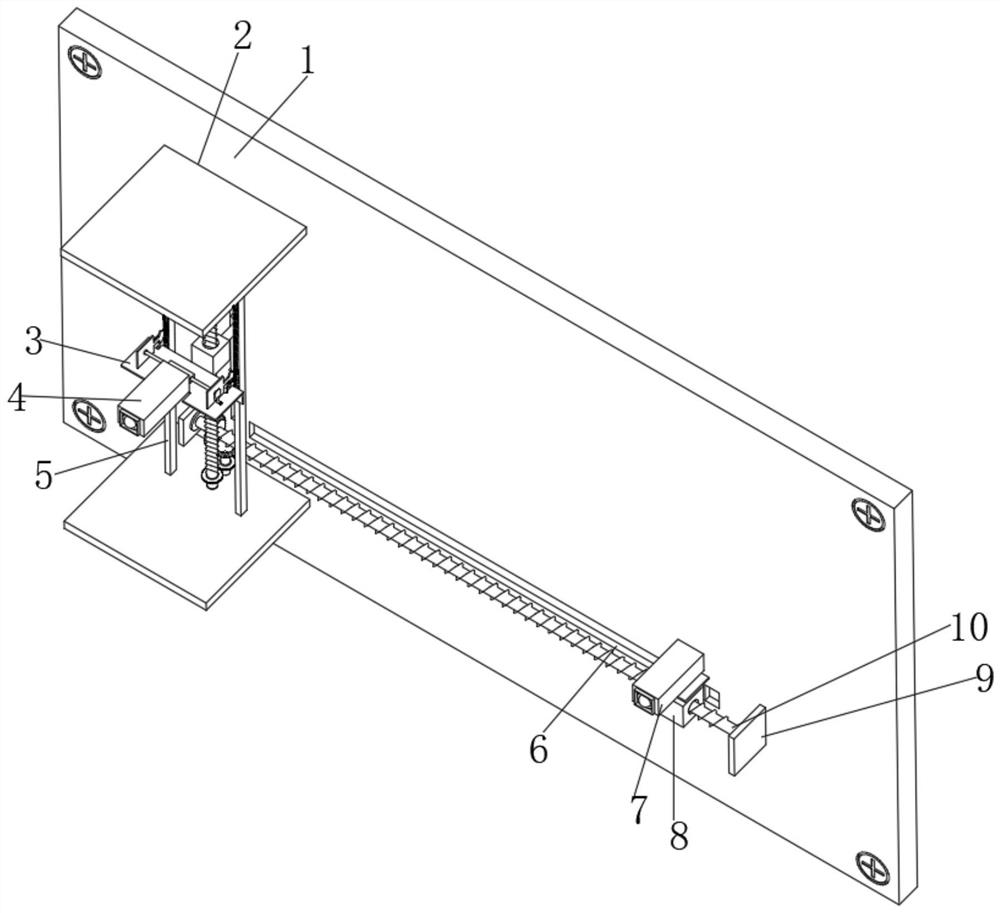

[0037] see Figure 1-10 , a monitoring system for an electric machine room, comprising a mounting plate 1, a positioning hole is provided on one side of the outer wall of the mounting plate 1, the number of the positioning holes is four groups, and the four groups of positioning holes are respectively located on the mounting plate 1 At the four corners of the four positioning holes, fixing bolts are plugged inside the four positioning holes, a horizontal plate 2 is fixedly connected to one side of the outer wall of the mounting plate 1, and a lifting assembly is fixedly connected to the bottom outer wall of the horizontal plate 2, so One side of the lifting assembly is fixedly connected with a first fixed plate 3, the top of the first fixed plate 3 is provided with a rotating assembly, one side of the rotating assembly is fixedly connected with a first camera 4, the mounting plate 1 One side is provided with an adj...

Embodiment 2

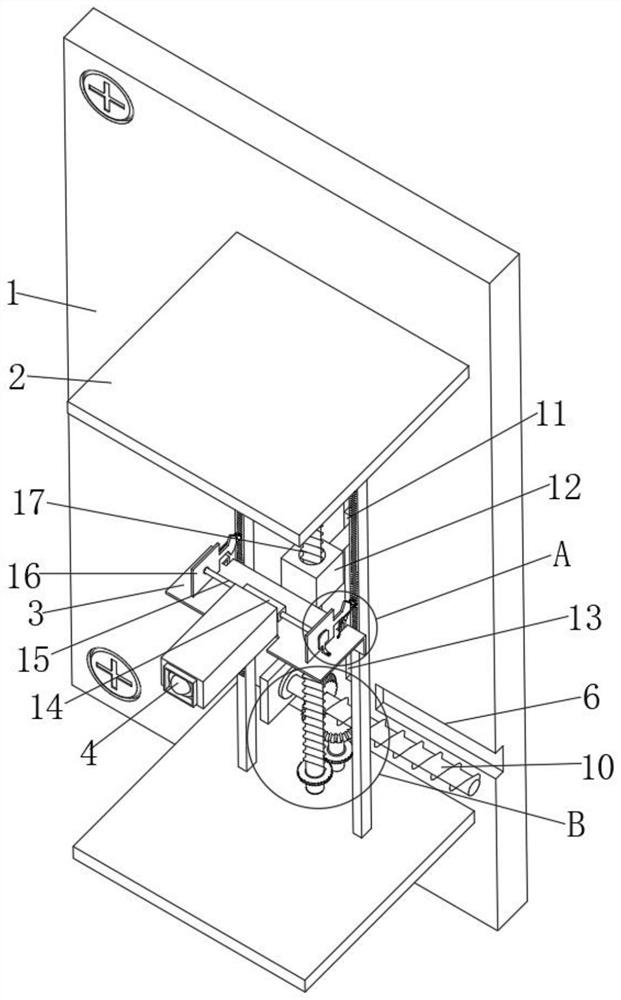

[0039] see Figure 4-7 , the lifting assembly includes a first motor 30 fixedly connected to the outer wall of the bottom of the horizontal plate 2, one end of the output shaft of the first motor 30 is fixedly connected with a second threaded screw 17, and the second threaded screw 17 The peripheral outer wall of the second threaded sleeve 12 is threadedly connected, the first fixing plate 3 is fixedly connected on one side outer wall of the second threaded sleeve 12, and the one side outer wall of the mounting plate 1 is fixedly connected with a fixed Frame 31, one side of the outer wall of the fixed frame 31 is fixedly connected with a slanting rod, the end of the slanted rod away from the fixed frame 31 forms a fixed connection with the first motor 30, and one side of the outer wall of the mounting plate 1 A second chute 13 is provided, the inner walls of both sides of the second chute 13 are slidably connected with the first slider 11, and the outer wall of one side of the...

Embodiment 3

[0041] see Figure 4 , 6 , the rotating assembly includes a support plate 24 fixedly connected to the top outer wall of the first fixed plate 3, and a third fixed plate 16 is rotatably connected to one side of the outer wall of the support plate 24, and the third fixed plate 16 includes a rectangular part and fan-shaped part, the number of the rectangular part is two groups, one side outer wall of the horizontal plate 2 is fixedly connected with a support rod 5, and one side outer wall of the support rod 5 is provided with a second alveolar 21, the The top of the first fixed plate 3 is provided with a guide assembly, and the peripheral outer wall of the fan-shaped portion is provided with a first tooth groove 19, and the first tooth groove 19 is engaged with the guide assembly, and the guide assembly and the first tooth groove 19 are engaged with each other. The two tooth grooves 21 are meshed with each other, and the outer wall of one side of the third fixed plate 16 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com