Photovoltaic system direct-buried cable current-carrying type selection method

A photovoltaic system and cable technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as many influencing factors, difficult calculations, and inability to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, simulation method

[0043] In this embodiment, the present invention confirms the minimum load factor under the typical daily load curve through the simulation method, finally obtains the ampacity, and selects the cable accordingly.

[0044] The current-carrying capacity selection method of direct-buried cables for photovoltaic systems based on cyclic load curves includes the following steps:

[0045] (1) According to the hourly data of Pvsyst, the daily load cycle curve of the cable flowing in the photovoltaic system is fitted.

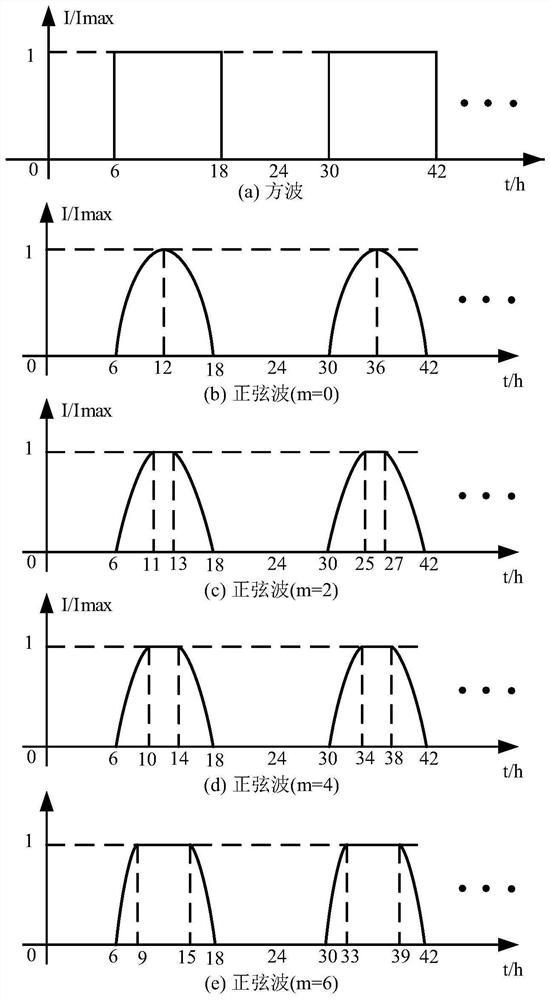

[0046] A typical load cycle curve is a sine wave. According to the Pvsyst simulation data, the limited hours can be confirmed, and the daily cycle load curve function can be approximately confirmed according to formulas (1)-(3).

[0047] (2) Based on the confirmed daily load cycle curve and the actual laying environment and configuration of the direct buried cable, calculate the steady-state ampacity Ir of the cable (IEC 60287 m...

Embodiment 2

[0071] Embodiment 2, look-up table method,

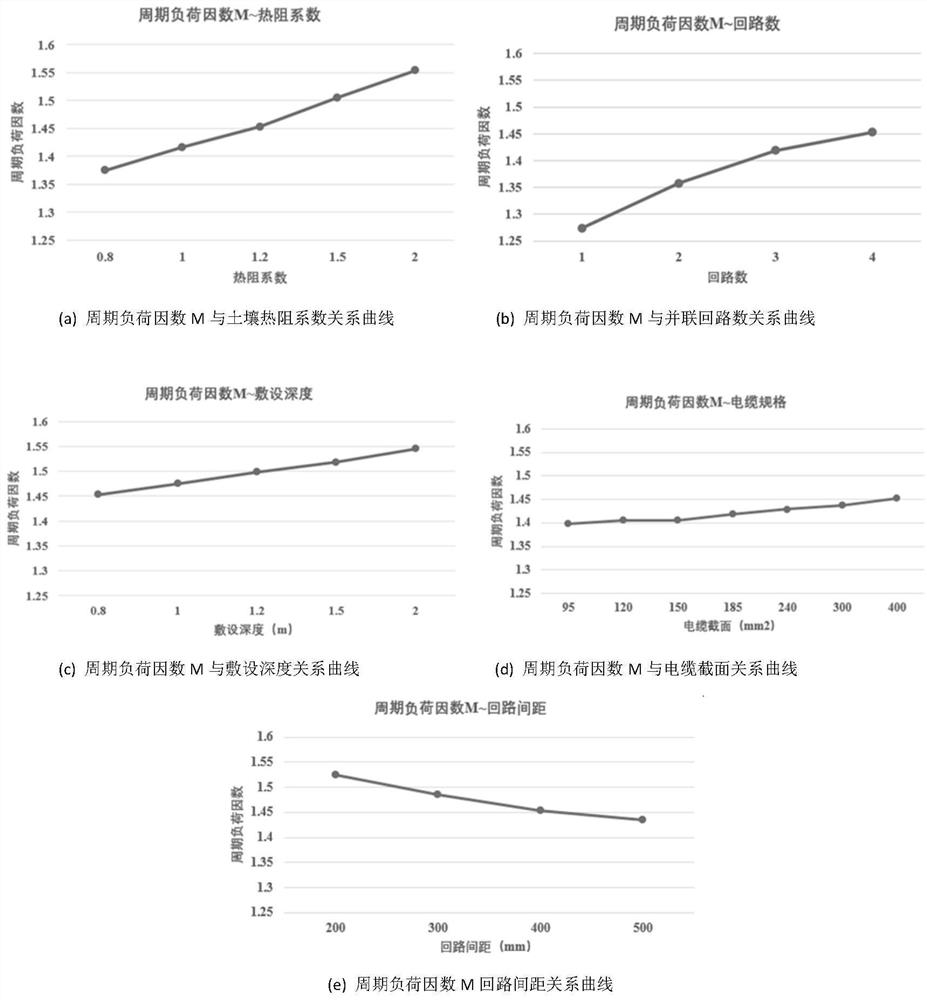

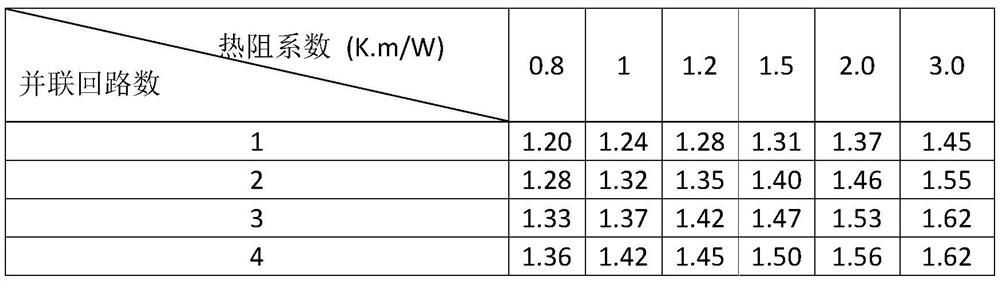

[0072] The table look-up method of the present invention is based on the results of the above-mentioned simulation method. When the thermal resistance varies between 0.8-2K.m / W, the number of loops varies between 1-4 loops, and the laying depth varies between 0.8-2m, the cable From three cores 70mm 2 ~400mm 2 When the distance between cables varies between 200 and 500, only the number of loops and the influence of thermal resistance coefficient on the M value are considered, the operation steps are simplified, it is convenient for practical engineering applications, and the cable cross section is effectively reduced to reduce the cable cost.

[0073] Taking the 35kV photovoltaic system as an example, the current-carrying capacity selection method of the 35kV direct-buried cable of the photovoltaic system based on the periodic load curve includes the following steps:

[0074] (1) Similar to the simulation method, first confirm the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com