Method and apparatus for treating solid waste

A solid waste, waste technology, applied in the direction of solid waste removal, chemical instruments and methods, transportation and packaging, etc., can solve the problems of inability to allow optimal treatment of substances and energy recovery, slow down anaerobic fermentation efficiency, etc., and achieve conversion time. short, cost reduction, avoid long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

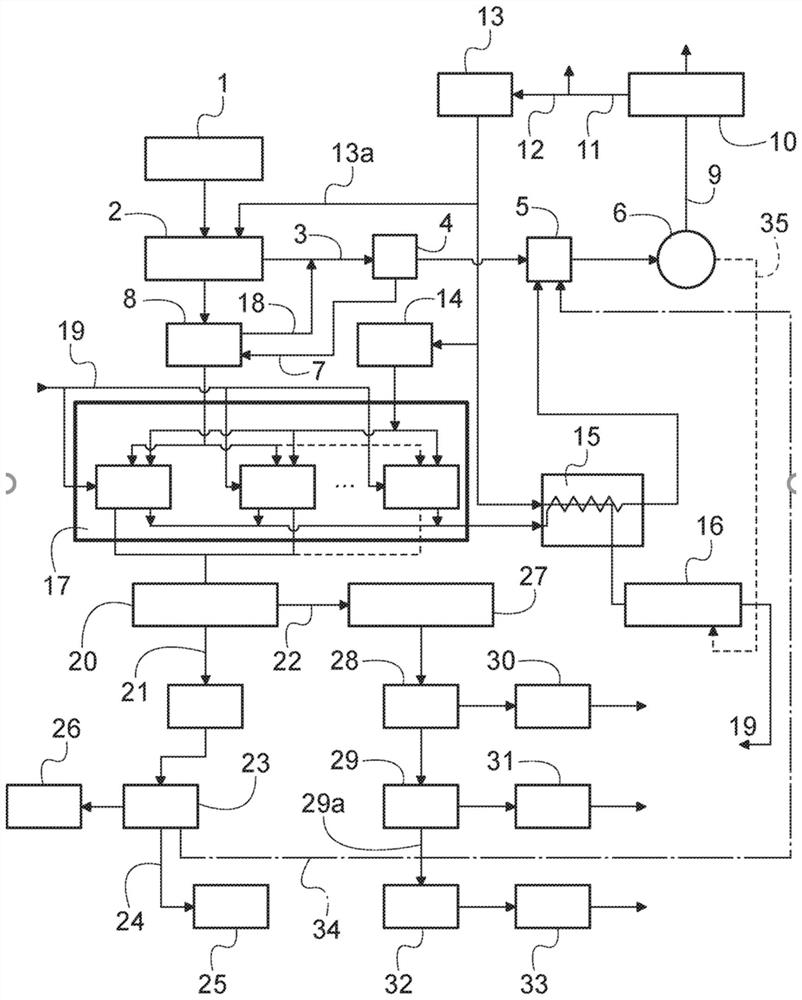

[0032] A method for treating solid waste. After receiving the waste at the receiving site 2, the waste is loaded into the batching system 8, and the batching system 8 is transferred to the SC device 17 in a predetermined amount by a conveyor belt for hydrothermal treatment. The leachate produced during the organic treatment of waste 1 is circulated to the biological digestion unit 6; after the solid waste 1 is weighed, a mandatory visual inspection is carried out on the ground of the receiving site 2, wherein the organic part of the municipal solid waste 1 and the municipal solid waste The organic part of 1 will contain a lot of leachate during the treatment process, and it will be discharged to the receiving field 2. The receiving field 2 has a certain slope, and the leachate is transported to the pre-storage device 5 by ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap