Automatic controllable deformation electromachining method for shape memory alloy flexible electrode

A memory alloy, flexible electrode technology, applied in metal processing equipment, electric processing equipment, electrochemical processing equipment and other directions, can solve the problems of increasing time cost, difficulty in tool electrode design, etc., to achieve simplified design, wide application range, good flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation process of the present invention will be described in detail below by taking the electrolytic machining of closed integral blisks as an example in conjunction with the accompanying drawings.

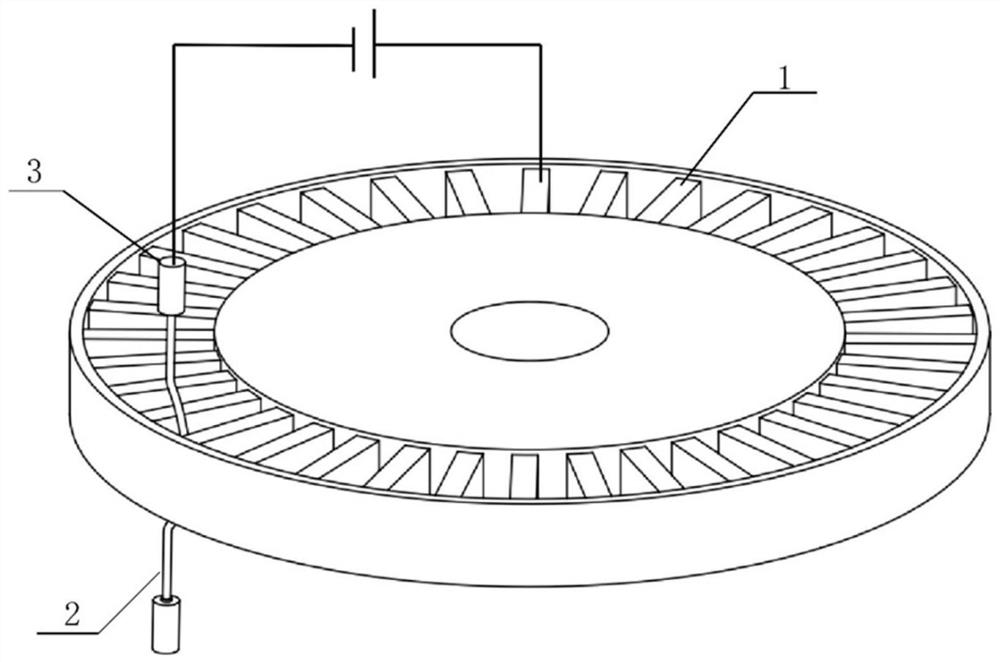

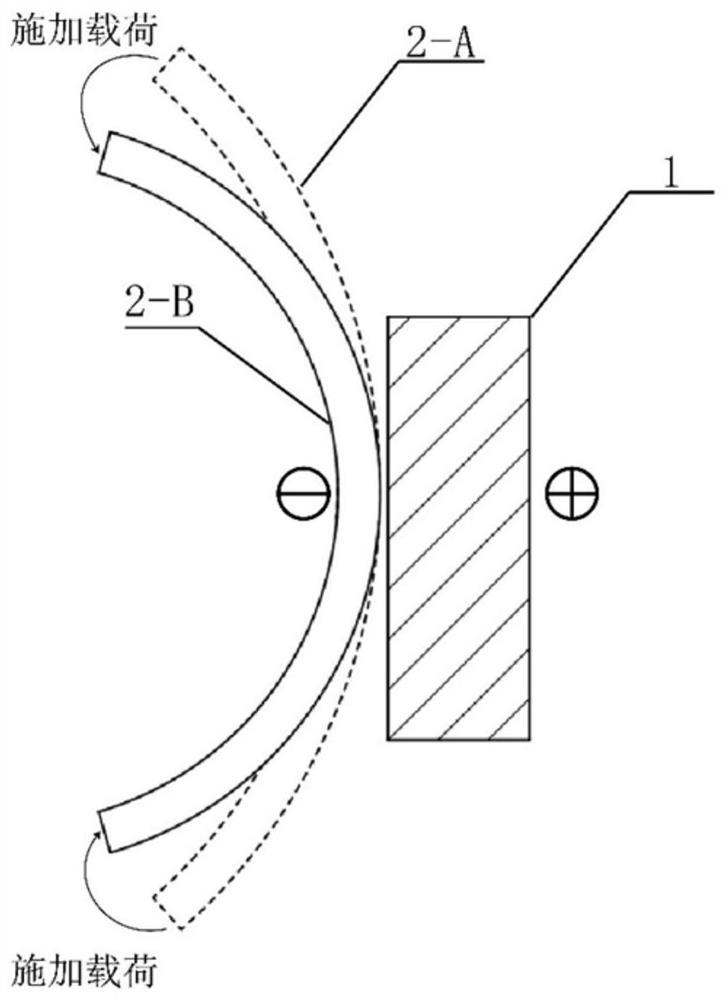

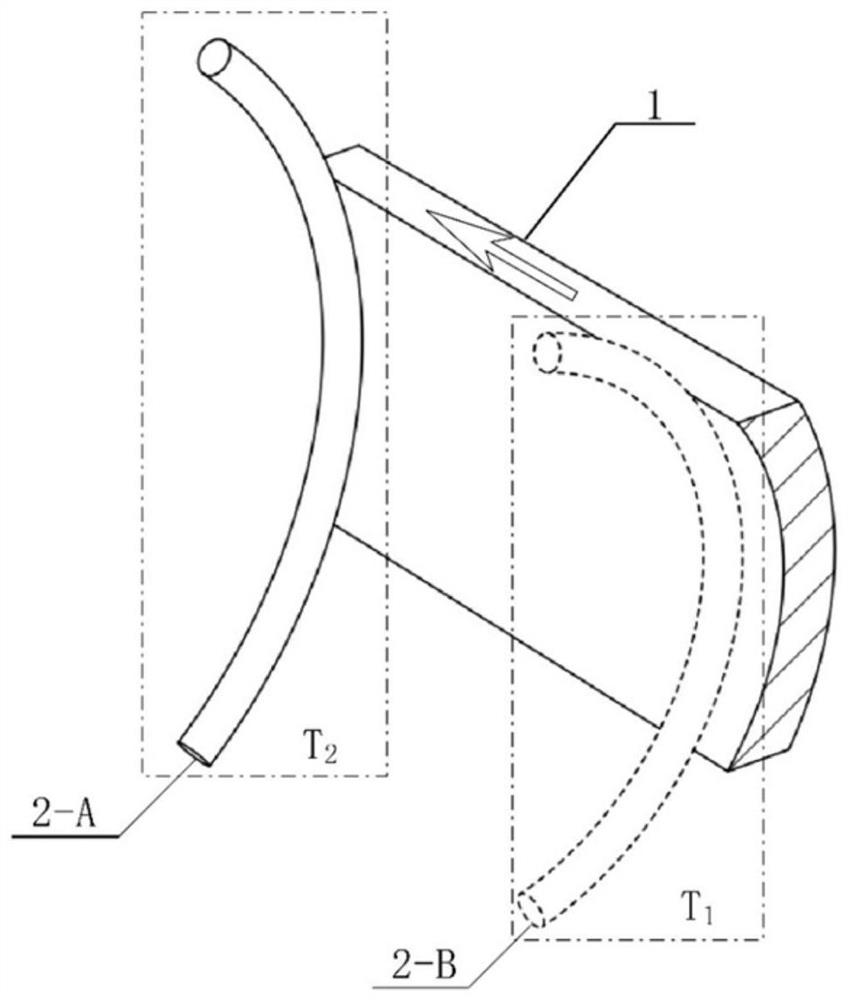

[0055] Such as figure 1 As shown, taking the electrolytic machining of a closed integral blisk as an example, the device for implementing the "electrical machining method for autonomous and controllable deformation of a shape memory alloy flexible electrode" of the present invention is mainly composed of a workpiece 1, a tool electrode 2, and an electrode clamping shaft 3 Composition, the workpiece 1 is connected to the positive pole of the power supply, the tool electrode 2 is connected to the electrode clamping shaft 3, and the electrode clamping shaft 3 is connected to the negative pole of the power supply. Wherein, the tool electrode 2 has two shapes, namely a preformed tool electrode 2-A and a deformed tool electrode 2-B.

[0056] Preparation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com