Polyurethane resin composition for synthetic leather with discoloration effect and preparation method thereof

A polyurethane resin and composition technology, applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problems of poor discoloration effect of wax powder, scrapping of synthetic leather products, yellowing of coatings, etc., and achieve film formation Good effect, suitable drying speed and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

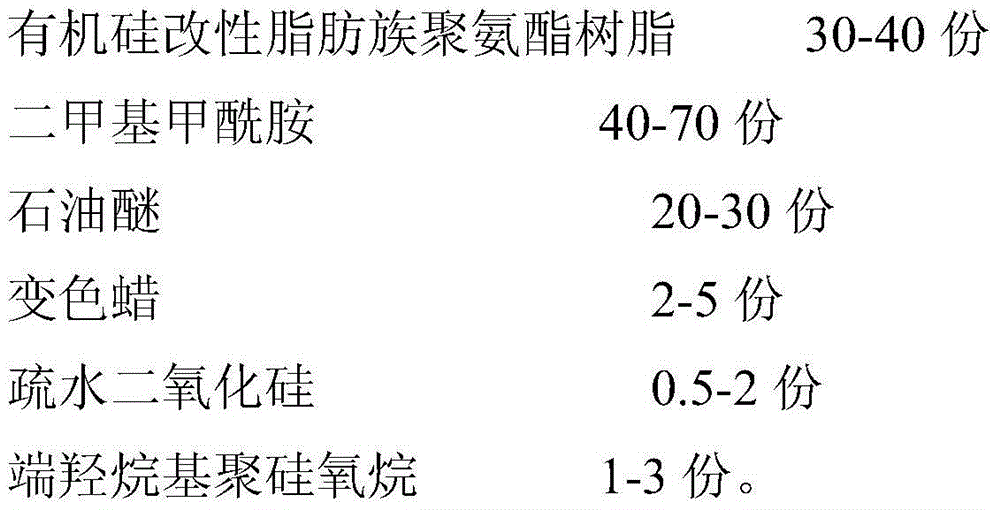

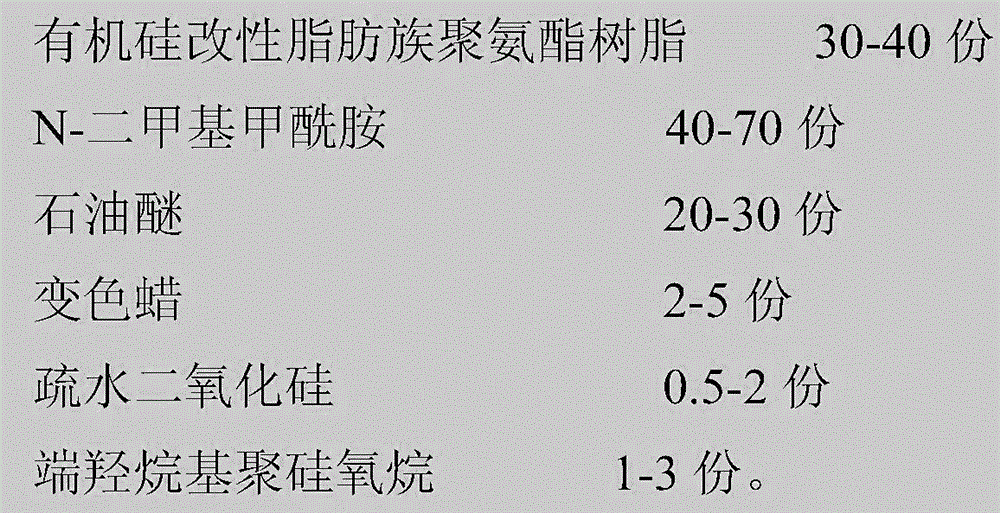

Method used

Image

Examples

Embodiment 1

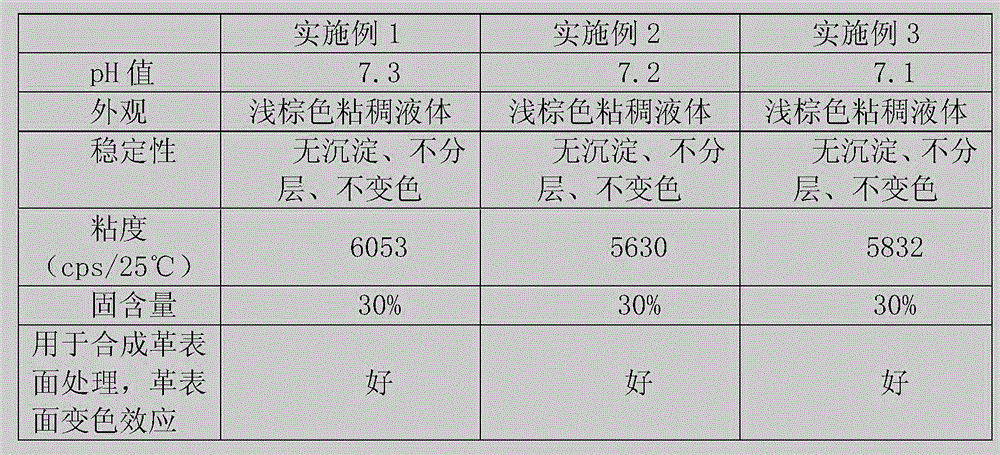

[0016] Take 2.5 parts of color-changing wax, 1.5 parts of hydrophobic silicon dioxide, 1.5 parts of hydroxyalkyl polysiloxane, 20 parts of petroleum ether, stir well, then add 61.5 parts of N-dimethylformamide, stir well, and then stir While adding 30 parts of silicone-modified aliphatic polyurethane resin, stirring evenly, filtering, and discarding the filter residue, the above-mentioned polyurethane resin composition for synthetic leather with discoloration effect is obtained.

Embodiment 2

[0018] 3.5 parts of discoloration wax, 1.0 parts of hydrophobic silicon dioxide, 2.0 parts of hydroxyalkyl polysiloxane, 25 parts of petroleum ether, stir evenly, then add 60 parts of N-dimethylformamide, stir evenly, and then stir While adding 30 parts of silicone-modified aliphatic polyurethane resin, stirring evenly, filtering, and discarding the filter residue, the above-mentioned polyurethane resin composition for synthetic leather with discoloration effect is obtained.

Embodiment 3

[0020] 4.0 parts of color-changing wax, 0.5 parts of hydrophobic silicon dioxide, 2.5 parts of hydroxyalkyl polysiloxane, 30 parts of petroleum ether, stir well, then add 56.5 parts of N-dimethylformamide, stir well, and then stir While adding 30 parts of silicone-modified aliphatic polyurethane resin, stirring evenly, filtering, and discarding the filter residue, the above-mentioned polyurethane resin composition for synthetic leather with discoloration effect is obtained.

[0021] The above organosilicon-modified aliphatic polyurethane resin can be prepared by using commercially available products and techniques disclosed in existing documents.

[0022] The ratio of N-dimethylformamide to petroleum ether will be different in spring, summer, autumn and winter. In summer, the proportion of petroleum ether is appropriately increased, and in winter, the proportion of petroleum ether is appropriately reduced, mainly according to the different volatilization of solvents in differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com