Ultra-clear matt finish paint with high resistance and yellowing resistance and preparation method of finish paint

A technology of anti-yellowing and high resistance, applied in the direction of coating, etc., can solve the problems of poor transparency, good transparency, poor gloss, etc., and achieve the effect of good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

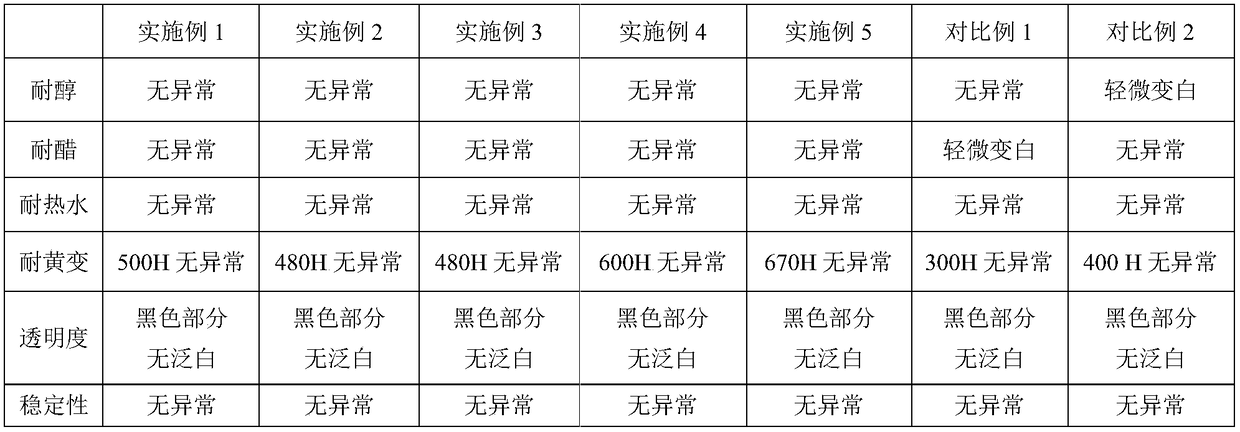

Examples

preparation example Construction

[0033] On the other hand, the present invention also provides a preparation method of a high-resistance, anti-yellowing special clear matte varnish, which comprises the following steps:

[0034] Step 1, add water-based acrylic resin, matte water-based acrylic resin and deionized water into the reactor and mix well;

[0035] Step 2, add defoamer at a speed of 500-600r / min, and disperse for 10-20min at a speed of 1000-1200r / min;

[0036] Step 3, pre-mix the film-forming aid, pH regulator and deionized water evenly and add them to the reaction kettle, disperse at 1000-1200r / min for 10-20min, until the fineness is ≤20μm, pH8-9 And no shrinkage cavity;

[0037] Step 4: Add a wetting and leveling agent into the reaction kettle, disperse for 15-20min at a speed of 600-800r / min; then add a thickener, and stir for 10-20min at a speed of 800-1000r / min, until the viscosity 65-75s.

[0038] Alcohol resistance described in the present invention is to test 1H in 50% ethanol solution.

...

Embodiment 1

[0046] A high-resistance, anti-yellowing ultra-clear matte varnish, wherein the topcoat includes 50 parts by mass of water-based acrylic resin and 20 parts by mass of matte water-based acrylic resin.

[0047] In the above scheme, the topcoat also includes: 4 parts by mass of film-forming aids, 0.2 parts by mass of pH regulators, 0.4 parts by mass of defoamers, 0.3 parts by mass of wetting and leveling agents, 10 parts by mass of Ionized water and 0.1 parts by mass of thickener. Wherein, the film-forming aid is DPM; the pH regulator is dimethylethanolamine; the defoamer is BYK-024; the wetting and leveling agent is Tego-4100; the thickener It is a polyurethane thickener.

[0048] Preparation:

[0049] Step 1, add water-based acrylic resin, matte water-based acrylic resin and deionized water into the reactor and mix well;

[0050] Step 2, add defoamer at a speed of 500-600r / min, and disperse for 10-20min at a speed of 1000-1200r / min;

[0051] Step 3, pre-mix the film-formi...

Embodiment 2

[0054] A high-resistance, anti-yellowing special clear matte varnish, wherein the topcoat comprises 60 mass parts of water-based acrylic resin, 25 mass parts of matte water-based acrylic resin and 30 mass parts of polyacrylate / nanometer ZnO composite emulsion, wherein the polyacrylate / nano ZnO composite emulsion has a solid content of 40%.

[0055] In the above scheme, the topcoat also includes: 6 parts by mass of film-forming aids, 0.4 parts by mass of pH regulators, 0.6 parts by mass of defoamers, 0.5 parts by mass of wetting and leveling agents, 15 parts by mass of Ionized water and 0.3 parts by mass of thickener. Wherein, the film-forming aid is DPNB; the pH regulator is AMP-95; the defoamer is TEGO902W; the wetting and leveling agent is BYK-346; the thickener is polyurethane thickener.

[0056] Preparation:

[0057] Step 1, add water-based acrylic resin, matte water-based acrylic resin and deionized water into the reactor and mix well;

[0058] Step 2, add defoamer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com