Atomization core sealing element installation work station and electronic cigarette automatic assembly production line

A technology for installing workstations and atomizing cores, which is used in assembly machines, tobacco, manufacturing tools, etc. to improve production efficiency and achieve uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

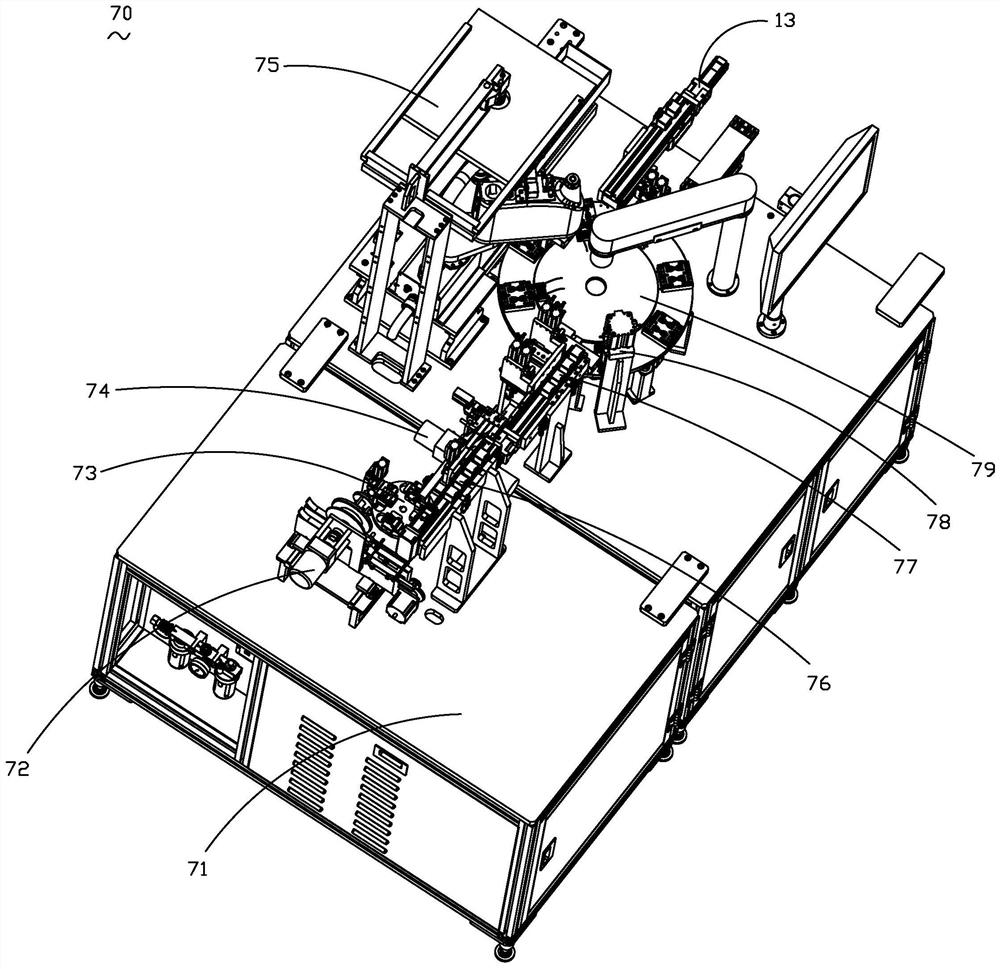

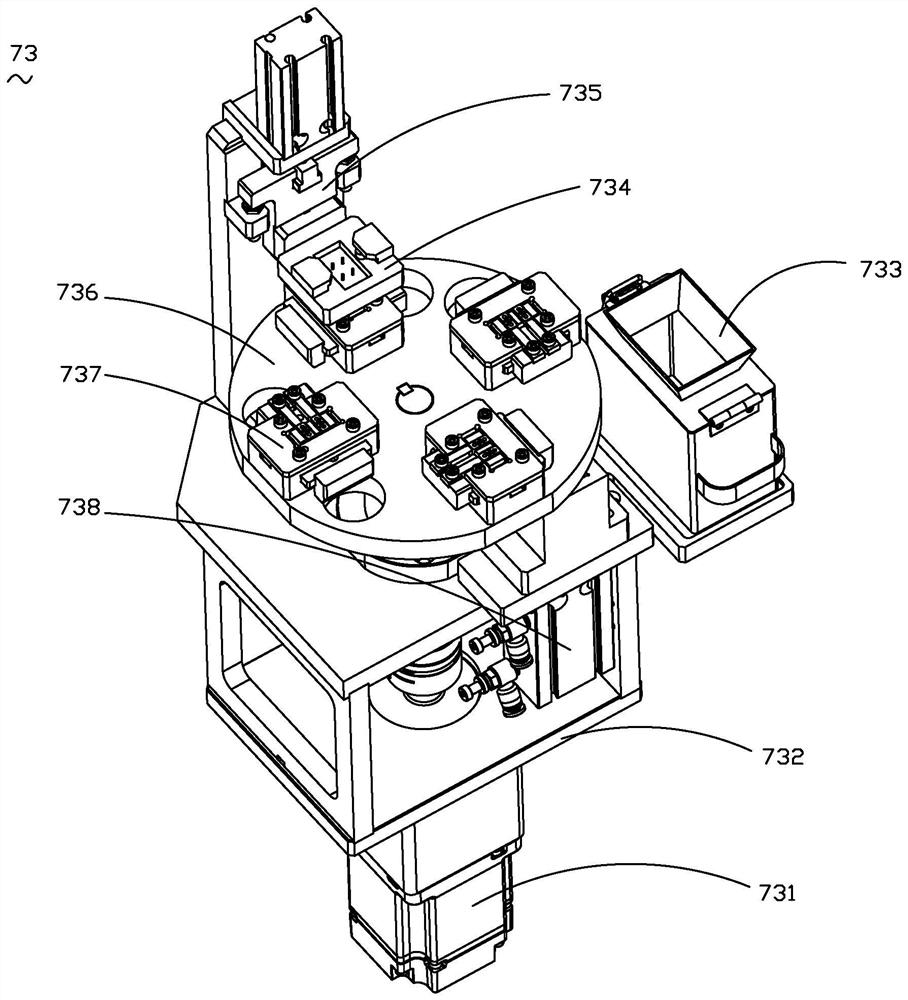

[0056] Embodiment 1: as Figure 1 to Figure 9 As shown, the atomizing core seal installation station 70 of this embodiment is used to assemble the atomizing core and the atomizing core seal 5 to form a first assembly, including: an atomizing core seal workbench 71, located on the The atomizing core feeding device 72 on the atomizing core seal workbench 71, the atomizing core resistance detection device 73, the suction head handling device 76, the double-track conveyor belt assembly 74, the atomizing core transfer and feeding mechanism 77, An atomizing core turntable assembly 79 , an atomizing core sealing member loading device 75 , a first assembly riveting device 78 , and a first assembly transfer and conveyance device 13 .

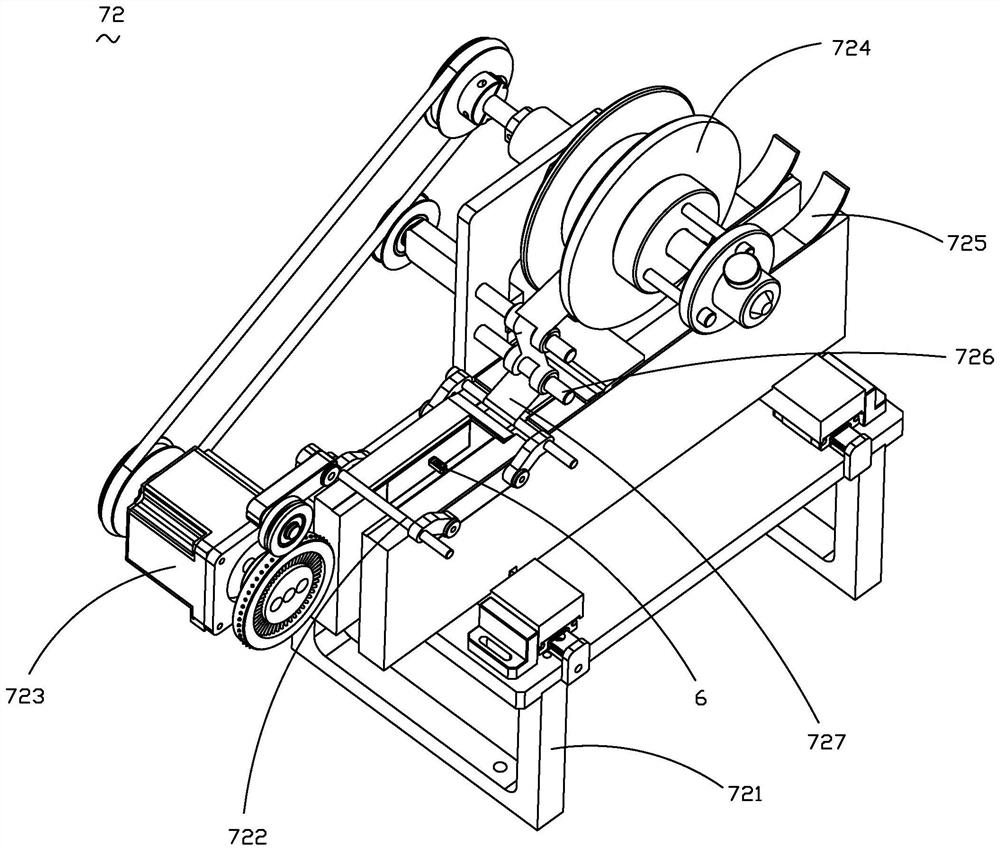

[0057] Such as figure 2 As shown, the atomizing core feeding device 72 includes a feeding mechanism fixing frame 721, a feeding rail 725 arranged on the feeding mechanism fixing frame 721, and a feeding motor fixed at the end of the feeding rail 725 7...

Embodiment 2

[0067] Embodiment 2: The electronic cigarette automatic assembly production line of this embodiment includes the atomizing core seal installation station 70 of Embodiment 1, and also includes the cartridge bracket installation station and the atomization core base installation station.

[0068] Such as Figure 10As shown, the pod holder installation station 10 is used to assemble the first assembly and the pod holder 4 to form a second assembly, which specifically includes a bracket turntable assembly 11 and brackets respectively arranged on the periphery of the bracket turntable assembly 11 Feeding device 12, first assembly transfer device 13 (shared with atomizing core seal installation station 70), bracket riveting device 14, second assembly defective product detection device 15 and second assembly output Device 16; the support turntable assembly 11 is used to carry the parts to be assembled and transport the parts to be assembled to the next station by rotating; the first ...

Embodiment 3

[0074] Embodiment 3: On the basis of Embodiment 2, the electronic cigarette automatic assembly production line of this embodiment also includes a bracket seal installation station 30, such as Figure 14 As shown, the support seal installation station 30 is used to assemble the third assembly and the support seal 3 to form a fourth assembly, including a workbench 31 and a support seal turntable assembly arranged on the workbench 31 38. The third assembly handling device 32, the bracket sealing material feeding device 33, the first shaping device 34, the second shaping device 35, and the fourth assembly riveting device respectively arranged on the periphery of the bracket seal turntable assembly 38 36, and the fourth assembly turning and discharging device 37. The third assembly is an assembly of the atomizing core 6 of the electronic cigarette, the atomizing core seal 5 , the pod bracket 4 and the atomizing core base 7 , and the third assembly is formed after being assembled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com