Five-shaft-head intelligent feedback device and processing machine tool

A feedback device and five-axis head technology are applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., which can solve the problems of not being able to obtain the working status information of the five-axis head in real time, and cannot guarantee the safety of the five-axis head. Extend the life cycle of equipment, improve the efficiency of equipment use, and correct the effect of using habits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

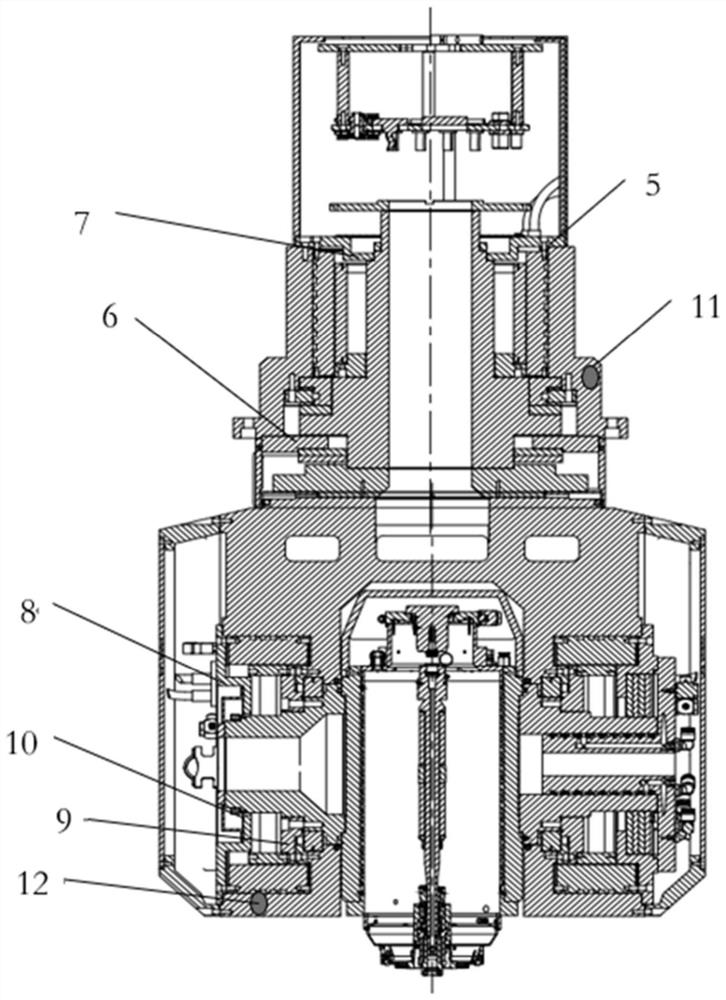

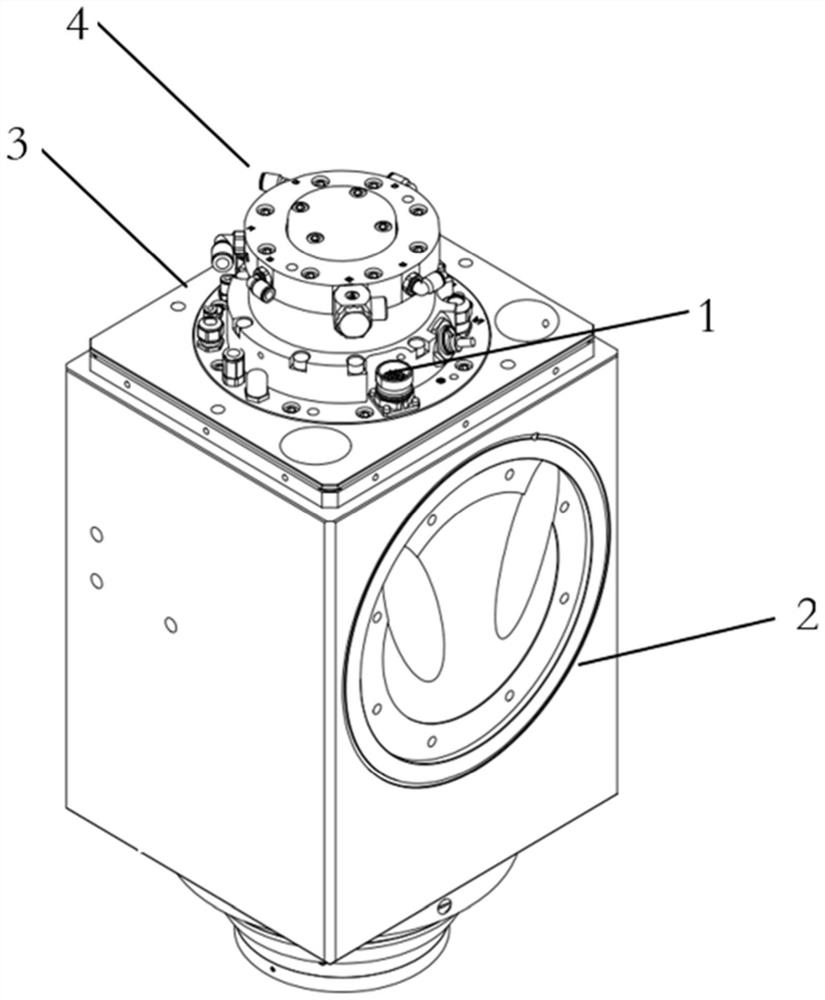

[0036] A five-axis head intelligent feedback device provided in this embodiment includes a spindle temperature monitoring component 1, a spindle external environment temperature monitoring component 2, a spindle bearing temperature monitoring component 3, a spindle oil-air lubrication flow monitoring component 4, and an A-axis temperature monitoring component 8 , A-axis bearing temperature monitoring component 9, A-axis pneumatic clamp pressure monitoring component 10, A-axis ambient temperature monitoring component 12, C-axis temperature monitoring component 5, C-axis bearing temperature monitoring component 6, C-axis pneumatic clamp pressure monitoring component 7 and the C-axis ambient temperature monitoring component 11, the spindle temperature monitoring component 1 is buried in the spindle motor coil, the spindle external ambient temperature monitoring component 2 is buried at the connection position between the spindle and the casting, and the spindle bearing temperature ...

Embodiment 2

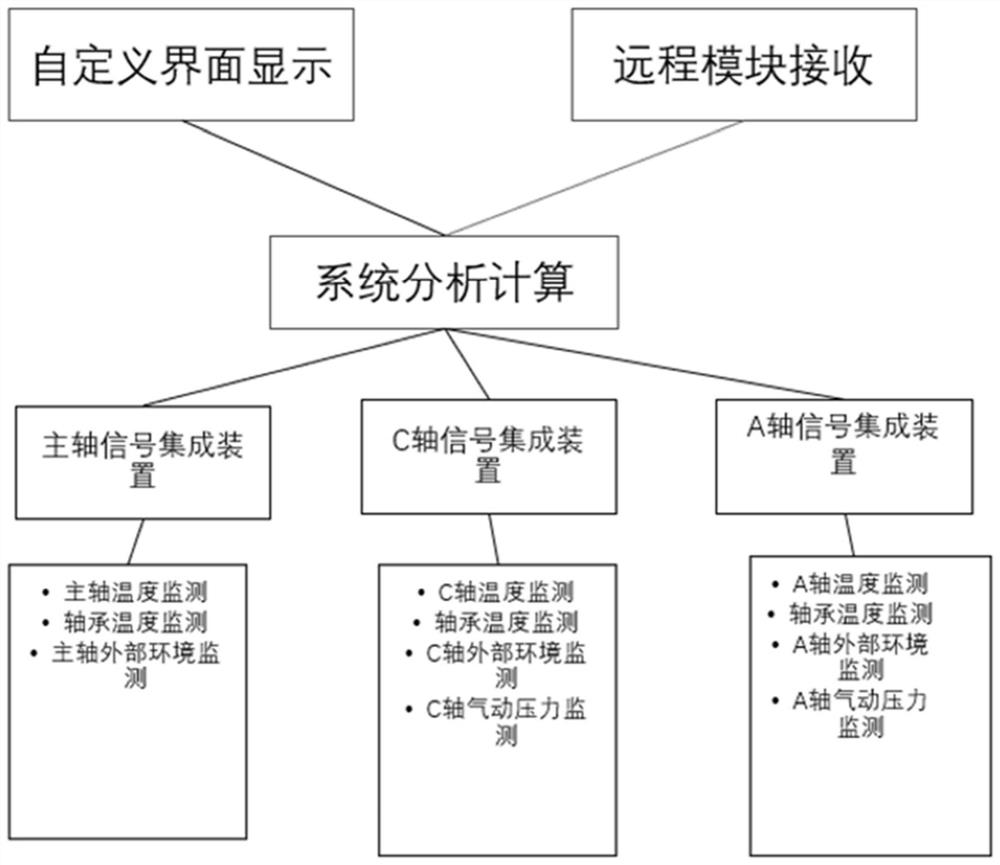

[0042] This embodiment provides a five-axis head intelligent feedback device. In this embodiment, a variety of sensors are added to the five-axis head to detect the use of the five-axis head in real time, and the remote module is used to monitor the use status of the equipment to avoid customer Due to changes in the application environment of water, electricity, and gas, equipment failures are caused, and the on-site brutal operation status is recorded at the same time.

[0043] This embodiment mainly records and protects through the following sensors:

[0044] Spindle temperature monitoring component 1: a set of KTY84 sensors, which are embedded in the spindle coil when the spindle is assembled, are used to monitor the temperature and cooling of the spindle coil;

[0045] Spindle external environment temperature monitoring component 2: Embed a group of PT100 temperature sensors at the connection position between the spindle device and the casting to monitor the peripheral tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com