Intelligent paper wrapping machine

A paper bag, intelligent technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to meet order response needs, long response time to orders, and high labor costs, achieving low production costs, wide application range, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings.

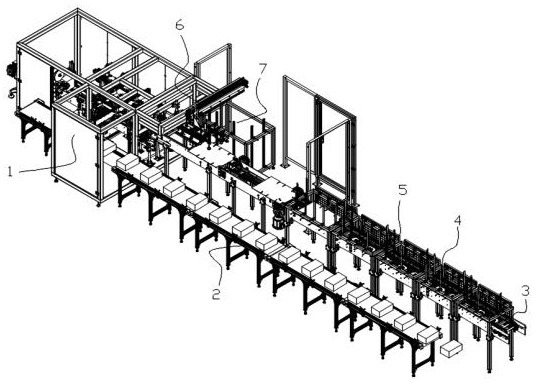

[0042] A smart paper bundle machine, such as figure 1 and Figure 5 As shown, including the packaging machine 1, the package machine 1 is provided with the product delivery mechanism 2 and the cardboard conveying mechanism 3, and the product delivery mechanism 2 is located on the left side of the cardboard conveying mechanism 3 and the height is lower than the cardboard conveying mechanism 3, the cardboard conveyor mechanism. 3 The right side is provided with a plurality of storage bin 4, and the cardboard conveying mechanism 3 is located at the bottom of the storage line 4, and the cardboard rejection mechanism 6 is provided on the left side of the cardboard conveying mechanism 6, close to the cardboard rejection mechanism 6 is provided with a cardboard collection. Cang 7.

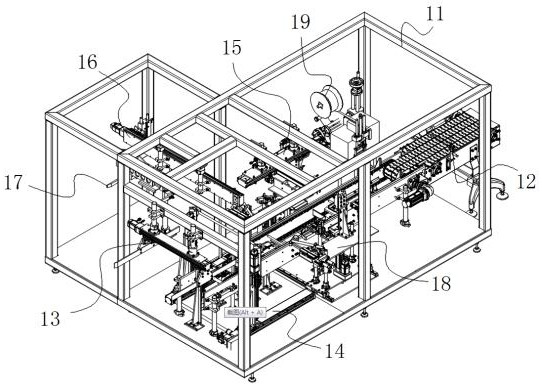

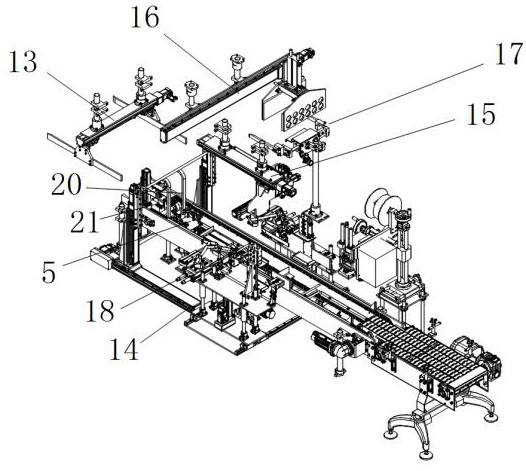

[0043] Such as Figure 2-3As shown, the packaging machine 1 includes a rack 11, a transfer mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com