Experimental platform of tower crane

A technology of tower cranes and experimental platforms, which is applied to cranes, traveling mechanisms, load blocks, etc., can solve problems such as risk costs, achieve the effects of reducing risks, reducing back and forth climbing tower cranes, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

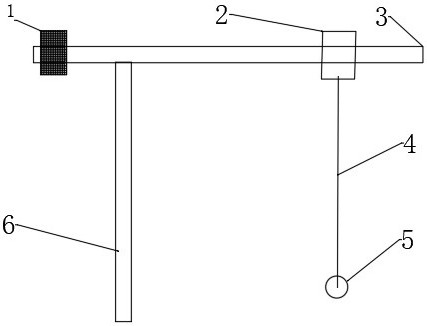

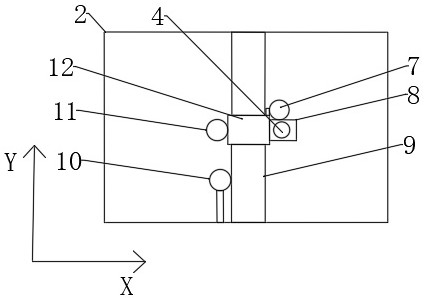

[0016] A tower crane experimental platform, such as figure 1 As shown, including the tower arm 3, the tower body 6, the lifting structure 2 and the drive mechanism, the tower arm 3 and the tower body 6 constitute the main structure of the T-shaped tower crane, the lifting structure 2 is arranged at the front end of the tower arm 3, and the lifting structure 2 There is a lightweight boom 4 below, and the lifting mechanism 2 can rotate the lightweight boom 4 to swing in two directions; the lightweight boom 4 is set through the lifting structure 2, and the lightweight boom 4 can be lifted along the lifting structure 2 The bottom of the lightweight boom 4 is provided with a hoisting object 5; the tail of the tower arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com