A swirl flood discharge tunnel with improved water flow

A technology of flood discharge tunnel and flow pattern, which is applied in the directions of hydroelectric power generation, water conservancy project, hydroelectric power station, etc., can solve the problems of unfavorable water flow pattern and large height of water flow in the vortex chamber, and achieves increased thickness, improved water flow pattern, and water surface climbing. The effect of high reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

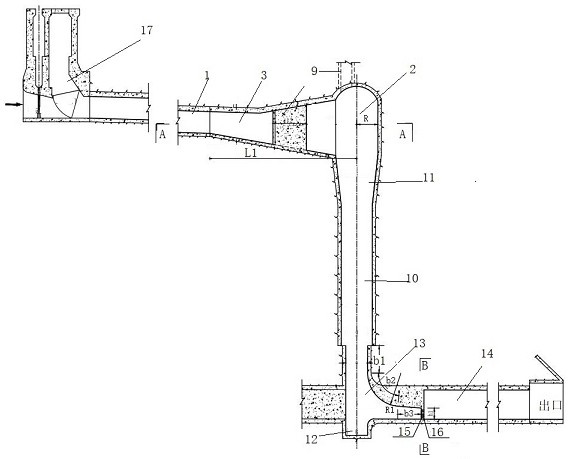

[0024] In order to overcome the problem that the water flow in the vortex chamber has a large rising height, which is unfavorable for the water flow shape in the existing shaft swirl flood discharge tunnel, the present invention provides such as Figure 1-3 As shown in a swirl flood discharge tunnel that improves the flow state of water flow, the present invention changes the flow state through the baffle plate at the end of the connecting section, so that the water flow regularly flows into the diversion hole, so as to ensure that the inner wall of the diversion hole will not be affected by excessive water flow. Erosion improves the service life of the diversion hole.

[0025] A swirl flood discharge tunnel for improving water flow, including a water diversion tunnel 1, a transition section 3, a vortex chamber 2, a vertical shaft 10, a stilling pool 12, a water baffle 15 and a diversion tunnel 14. The transition section 3 upstream It is connected with the water diversion tunn...

Embodiment 2

[0029] On the basis of Embodiment 1, in this embodiment, preferably, the transition section 3 is provided with a water dividing wall 4 .

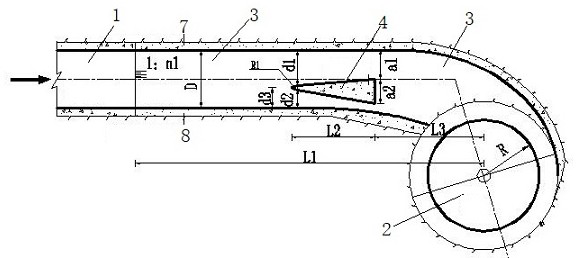

[0030] Preferably, the transition section 3 includes a base plate 5, a side wall 7, a side wall 2 8 and a top arch 6, and the side wall 1 7 and the side wall 2 8 are vertically arranged on the base plate, one outside and one inside. 5 and the top arch 6, the bottom plate 5 is inclined and arranged, the side wall 1 7 is arranged on the side away from the vortex chamber 2, and the side wall 2 8 is arranged on the side close to the vortex chamber 2, and its height is determined by the side wall of the water diversion tunnel 1. The wall height that transitions to the vortex chamber 2; the side wall 1 7 and the side wall 2 8 respectively include a straight section and an arc section along the water flow direction, the arc section of the side wall 7 is connected with the vortex chamber 2, and the arc section of the side wall 2 8 The section is co...

Embodiment 3

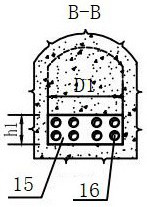

[0048] On the basis of Embodiment 1 or 2, preferably in this embodiment, the thickness of the side wall 1 7 is 50cm; the width D of the bottom plate 5 is 720cm, the slope ratio of the bottom plate 5 is 1:5, and the slope ratio of the slope section of the top arch 6 is 1 : 6. The radius R of the vortex chamber 2 is 630cm, the distance a1 between the backwater surface and the side wall 7 of the transition section 3 is 360cm, the width a2 of the backwater surface is 310cm, the arc radius R1 of the upstream surface is 150cm, and the side wall of the upstream surface is 150cm. The distance between the first 7 is d1 is 440cm, the distance d2 between the side wall 2 and the side wall 2 8 is 230 cm, the distance between the central axis of the upstream surface and the side wall 2 8 is d3 is 240 cm, the bottom plate 5 The distance between the slope point and the center line of the vortex chamber 2 is L1 is 4410cm, the downstream length L2 of the water separation wall 4 is 1000cm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com