Firing tool and firing method for THz glass insulator

A technology of glass insulators and tooling, which is applied in glass forming, glass manufacturing equipment, insulators, etc., can solve the problems of low product qualification rate and failure to adapt THz glass insulators to extremely small products, and achieve high product qualification rate and reduce creep. High, improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

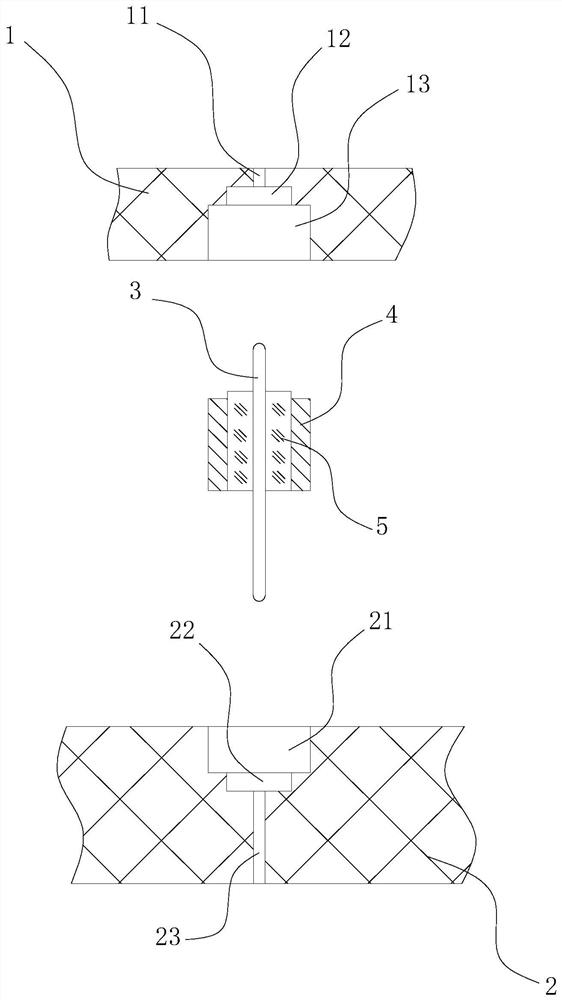

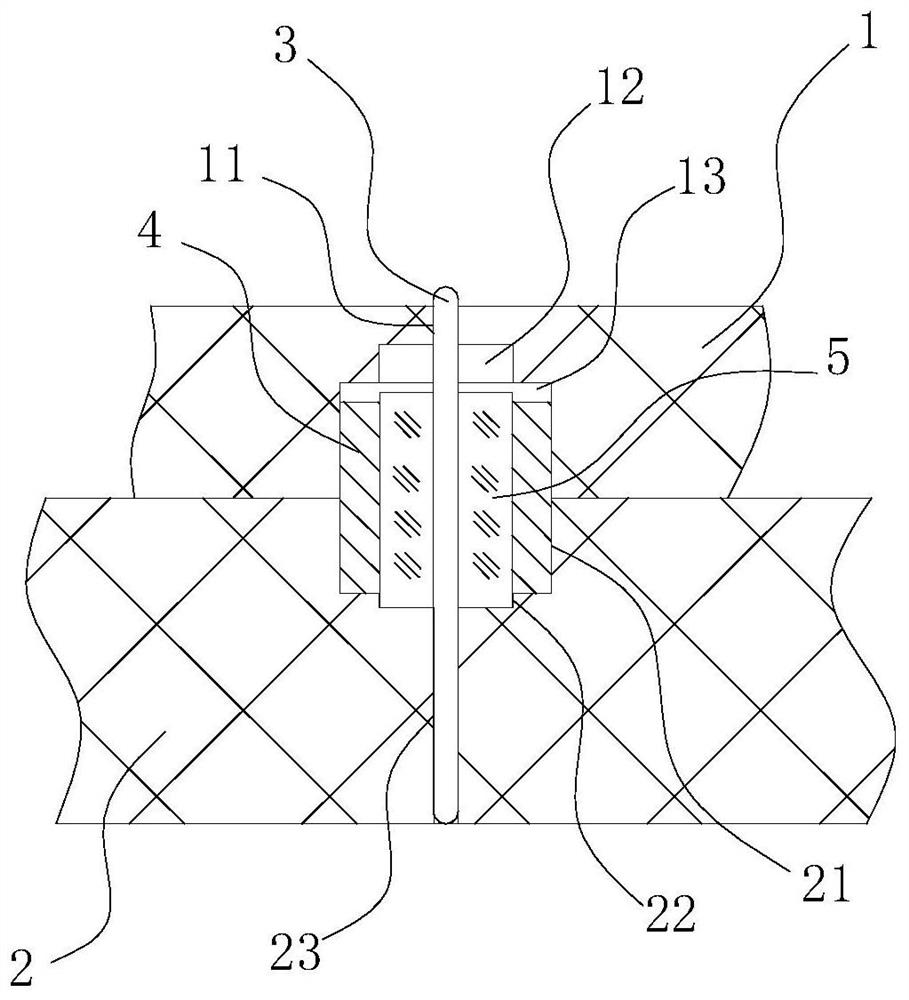

[0022] see figure 1 , figure 2 , a firing tooling for THz glass insulators, comprising an upper positioning tooling 1 and a lower positioning tooling 2 arranged at intervals up and down, the lower side of the upper positioning tooling 1 is provided with a first hole 11, a second hole 12, and a third hole arranged up and down. Holes 13, the diameter of the first hole 11 is 0.127mm, the diameter of the second hole 12 is 0.7mm, the diameter of the third hole 13 is 1.1mm, the upper side of the lower positioning tool 2 is provided with the fourth hole 21 and the fifth hole arranged up and down 22. The sixth hole 23, the fourth hole 21 has the same diameter as the third hole 13, the fifth hole 22 has the same diameter as the second hole 12, the sixth hole 23 has the same diameter as the first hole 11, the first hole 11, the second hole The hole 12 , the third hole 13 , the fourth hole 21 , the fifth hole 22 , and the sixth hole 23 are coaxial and the axial directions are all verti...

Embodiment 2

[0024] see Figure 1 ~ Figure 3 , a firing method of a firing frock of a THz glass insulator, comprising the following steps:

[0025] (1) Set the glass blank 5 between the inner conductor 3 and the outer conductor 4, put it into the lower positioning tool 2, then cover the upper positioning tool 1, so that the lower part of the inner conductor 3 is located in the sixth hole 23, and the outer conductor 4 The lower part is located in the fourth hole 21, the upper part of the inner conductor 3 is located in the first hole 11, and the upper part of the outer conductor 4 is located in the third hole 13;

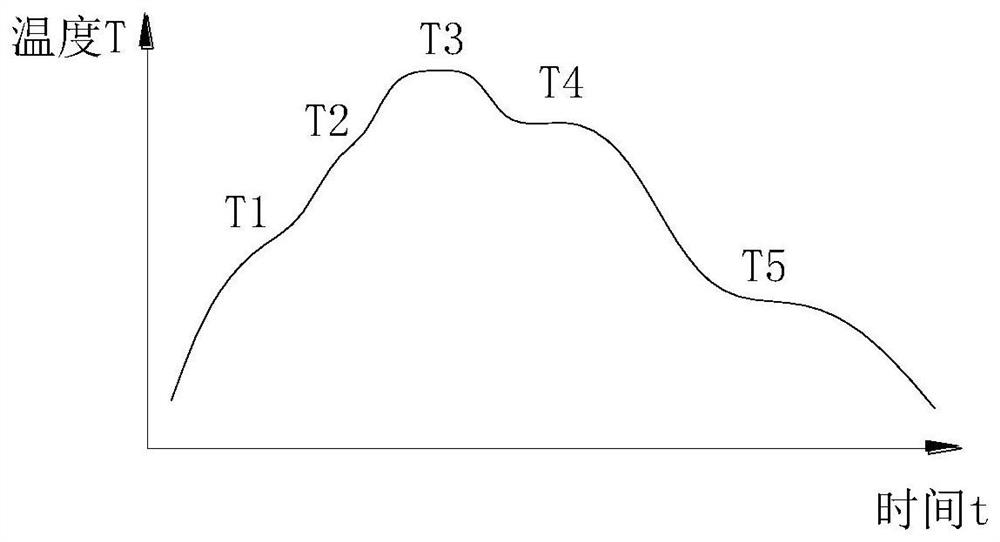

[0026] (2) Start firing, first heat up from room temperature for 40 minutes to T1, keep warm for 5 minutes, and T1 is 410°C;

[0027] (3) Reheat for 20 minutes from T1 to T2, keep warm for 9 minutes, and T2 is 620°C;

[0028] (4) Reheat for 20 minutes from T2 to T3, keep warm for 5 minutes, and T3 is 970°C;

[0029] (5) Naturally cool down to T4, keep warm for 5 minutes, and T...

Embodiment 3

[0032] see Figure 1 ~ Figure 3 , a firing method of a firing frock of a THz glass insulator, comprising the following steps:

[0033] (1) Set the glass blank 5 between the inner conductor 3 and the outer conductor 4, put it into the lower positioning tool 2, then cover the upper positioning tool 1, so that the lower part of the inner conductor 3 is located in the sixth hole 23, and the outer conductor 4 The lower part is located in the fourth hole 21, the upper part of the inner conductor 3 is located in the first hole 11, and the upper part of the outer conductor 4 is located in the third hole 13;

[0034] (2) Start firing, first heat up from room temperature for 40 minutes to T1, keep warm for 5.5 minutes, and T1 is 420°C;

[0035] (3) Reheat for 20 minutes from T1 to T2, keep warm for 9.5 minutes, and T2 is 630°C;

[0036] (4) Reheat for 20 minutes from T2 to T3, keep warm for 5 minutes, and T3 is 970°C;

[0037] (5) Cool down to T4 naturally, keep warm for 5.5min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com