Thrust integrated water-lubricated bearing for rim propeller

A technology of water-lubricated bearings and propellers, which is applied in the direction of sliding contact bearings, bearings, shafts and bearings, etc., to achieve the effect of improving the integration, avoiding the instability of adhesive installation, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

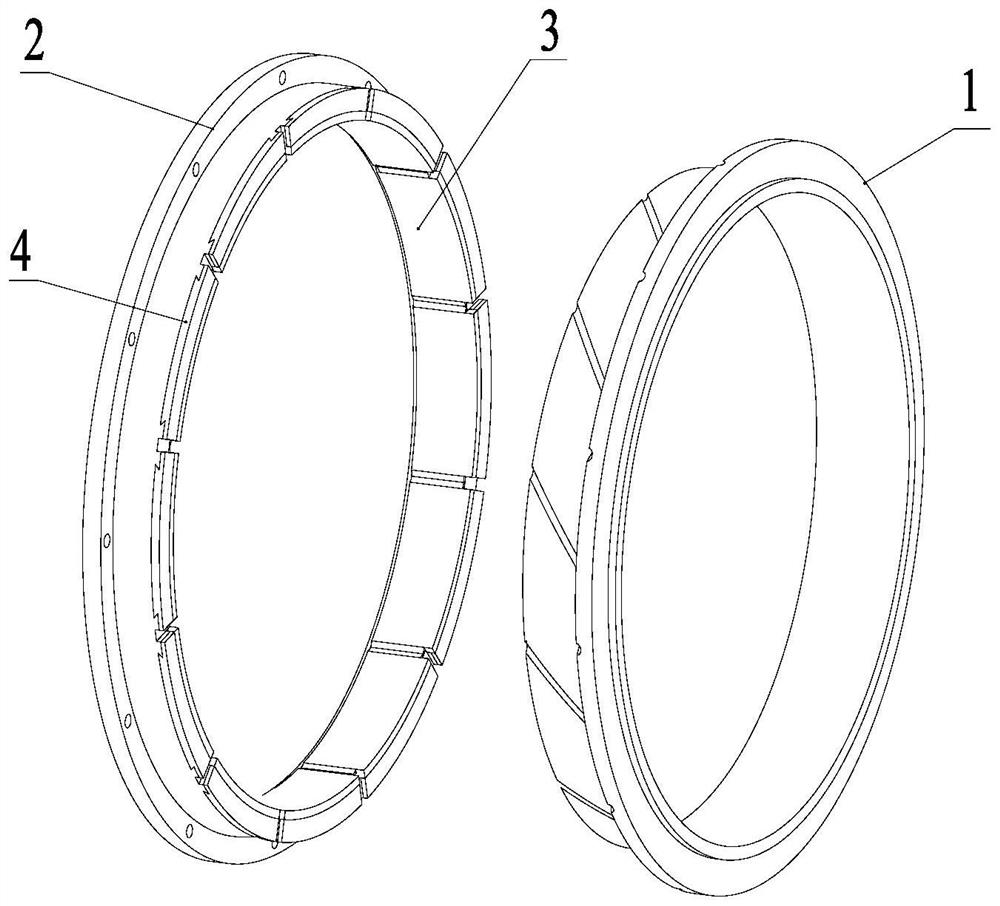

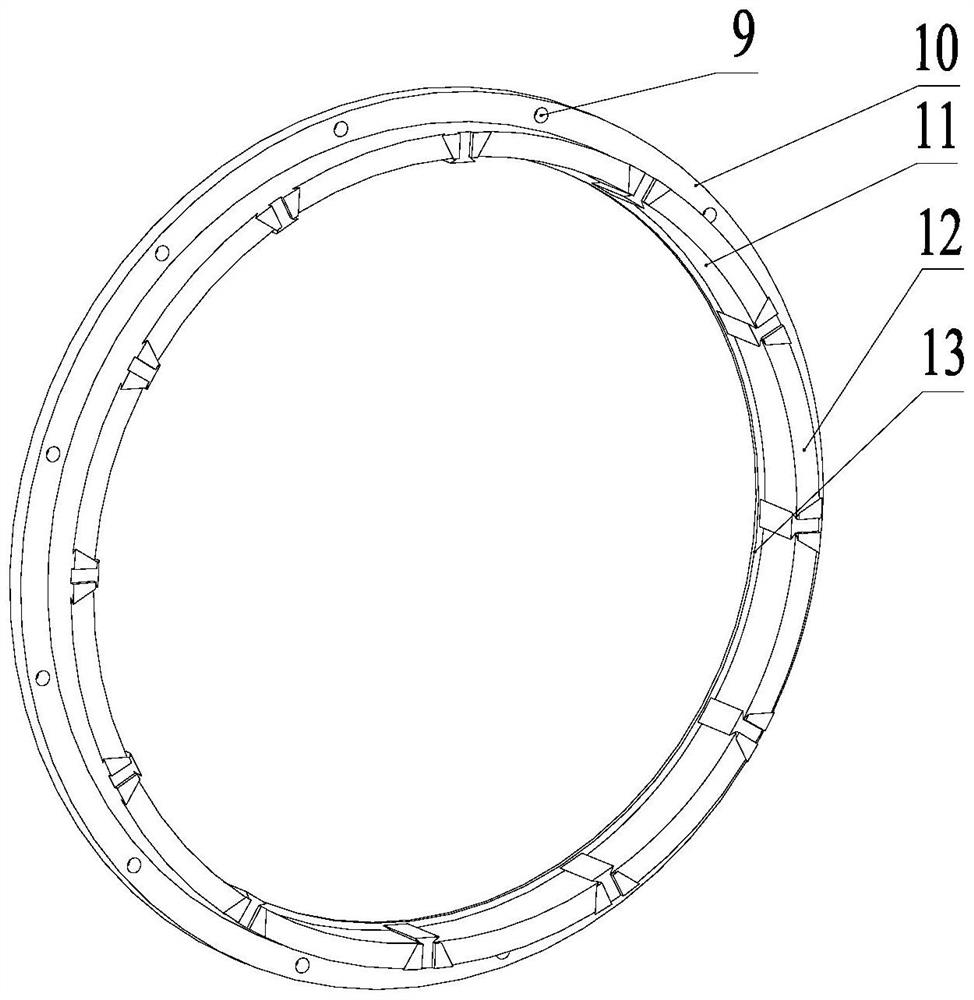

[0027] Such as Figure 1 to Figure 5 As shown, the thrust integrated water-lubricated bearing for the rim propeller of the present invention includes a rotor support ring 1 , a bearing body 2 , radial pads 3 , and axial pads 4 .

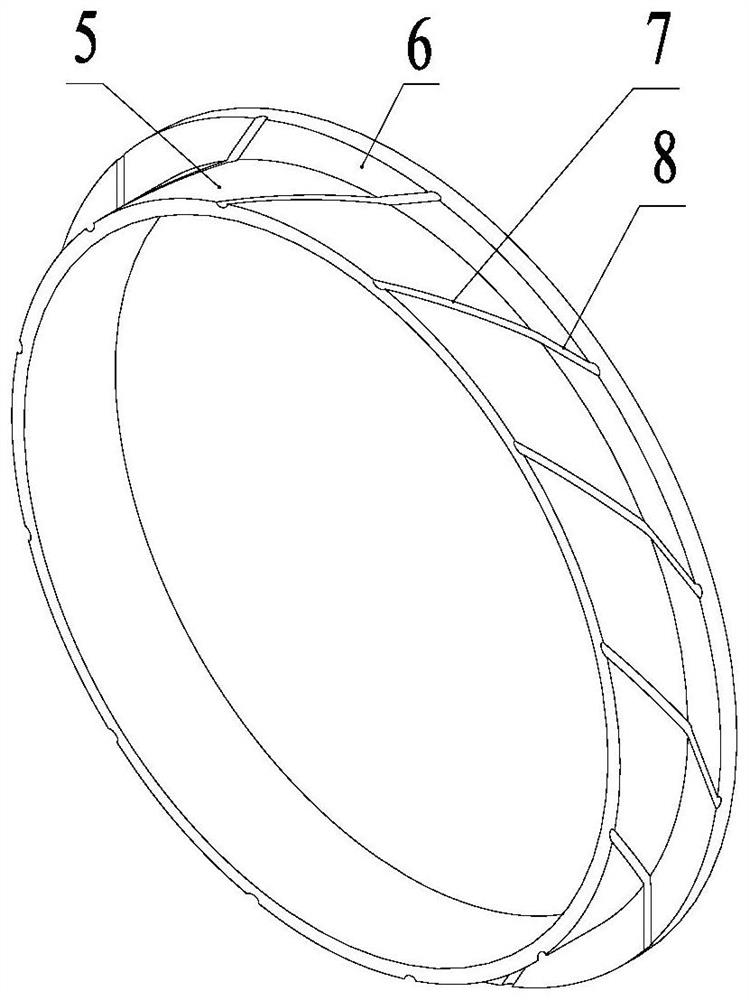

[0028] The rotor support ring 1 is equipped with 2 pieces in the rim propeller, and is connected with the motor rotor and both ends of the blade. The load is transmitted in the way that the outer ring 5 and the end face 6 of the rotor support ring 1 with the spiral water groove 1 7 and the spiral water groove 2 8 are respectively connected with the bearing block 2 20 and the axial bearing block 2 on the radial pad 3 of the thrust integrated water-lubricated bearing The bearing block one 16 on the tile 4 makes contact.

[0029] The rotor support ring 1 is only the structure on the left side of the rim propeller, and the rim p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com