Automatic flaw detection device for drill rod

A flaw detection device and drill pipe technology, which is used in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of high labor intensity, wrong judgment, accelerated physical fatigue of inspectors, etc. The effect of reducing detection risk, improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

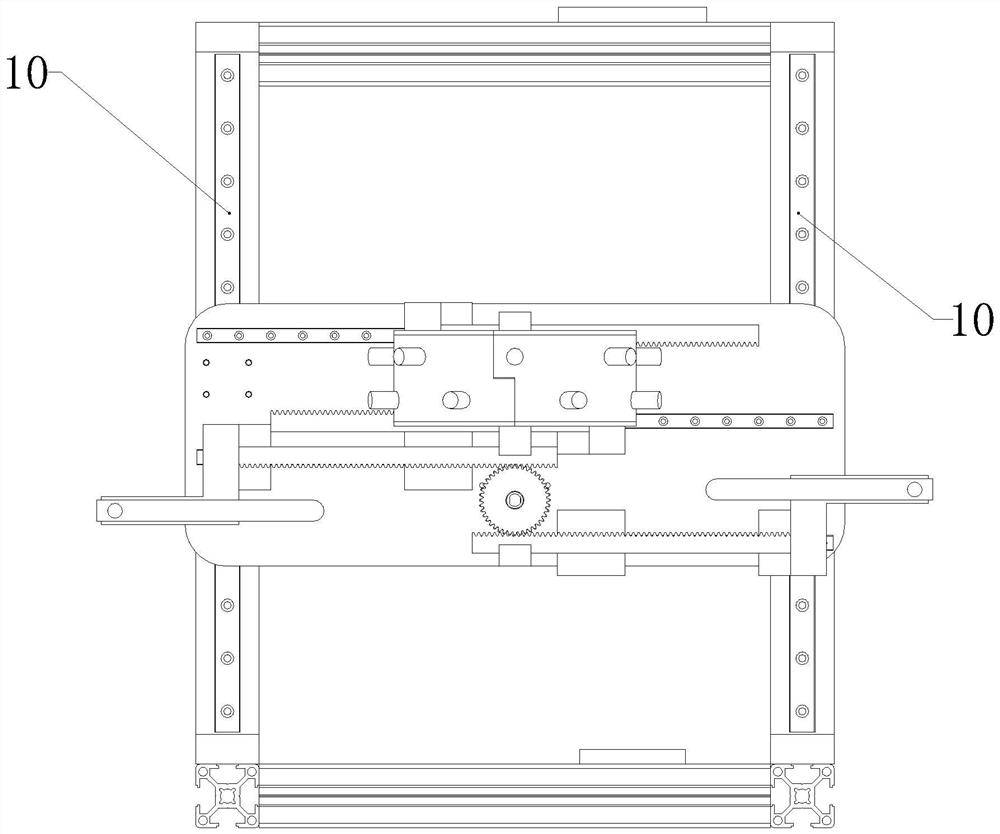

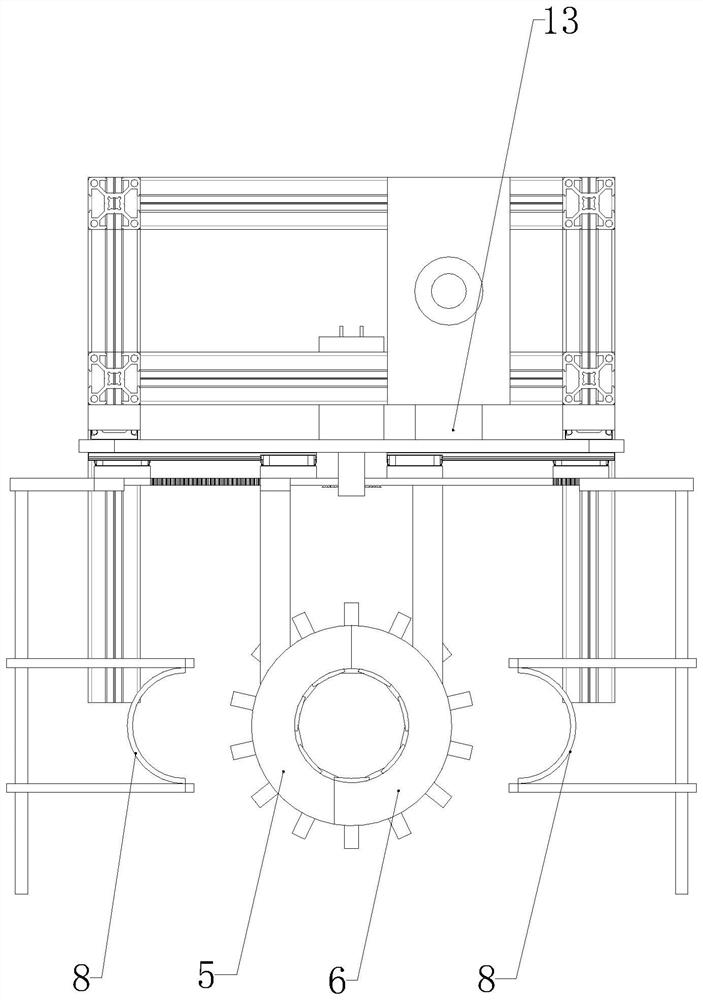

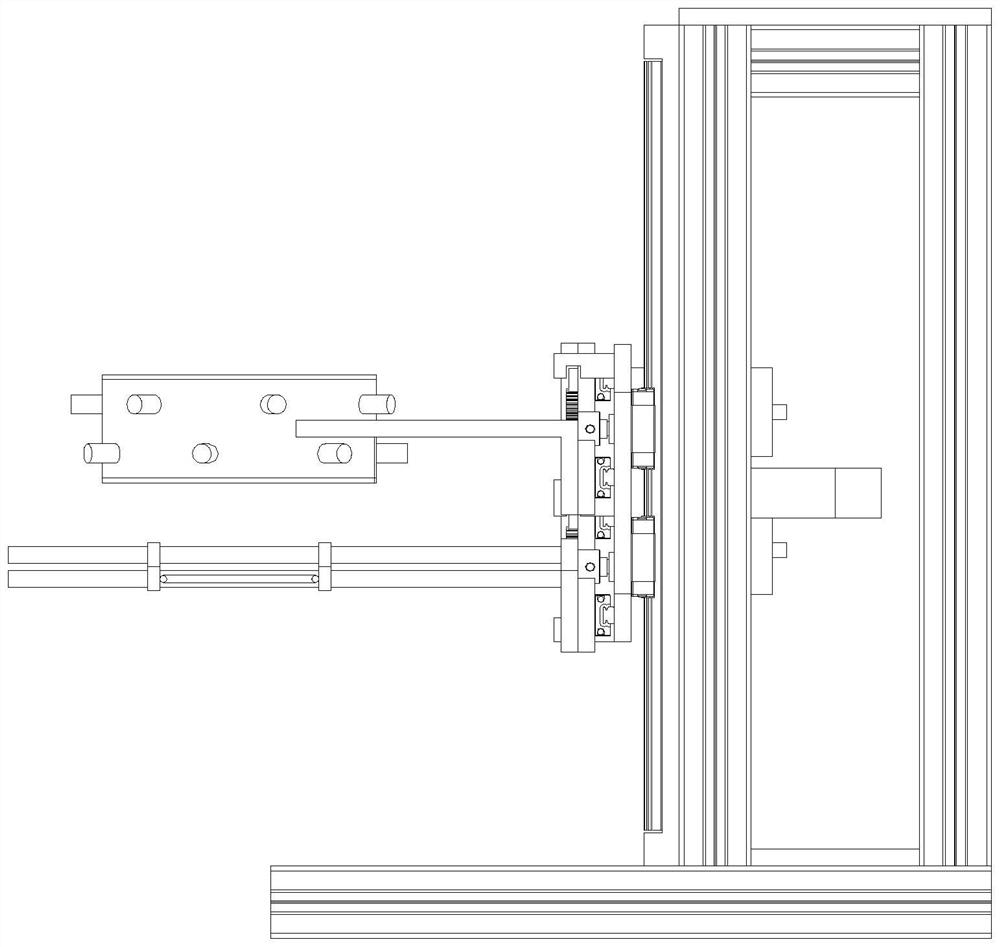

[0030] see Figures 1 to 11 , the drill pipe automatic flaw detection device of the present embodiment comprises a frame 1, a lifting plate 2 arranged on the frame, a lifting driver for driving the lifting plate to lift, the lifting plate is provided with a probe assembly and a decontamination assembly, and the probe assembly includes a probe The mounting ring 3 and a plurality of scanning probes 4 are arranged on the inner wall of the probe mounting ring. The probe mounting ring includes the left part 5 of the mounting ring and the right part 6 of the mounting ring. The left part of the mounting ring and the right part of the mounting ring can be driven on the lifting plate. The installation ring displacement driver that moves toward each other or moves away from each other, the decontamination assembly includes a connecting frame 7 and a decontamination rope 8 located on the connecting frame, and the lifting plate is also provided with a connecting frame driver that drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com