Preoperative salt-containing sterilization bath liquid and preparation method thereof

A technology of bath liquid and bactericide, which is applied in the field of preoperative salt-containing sterilizing bath liquid and its preparation, can solve the problems of inability to achieve effective bactericidal effect, and achieve significant bactericidal effect, rich and delicate foam, and good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

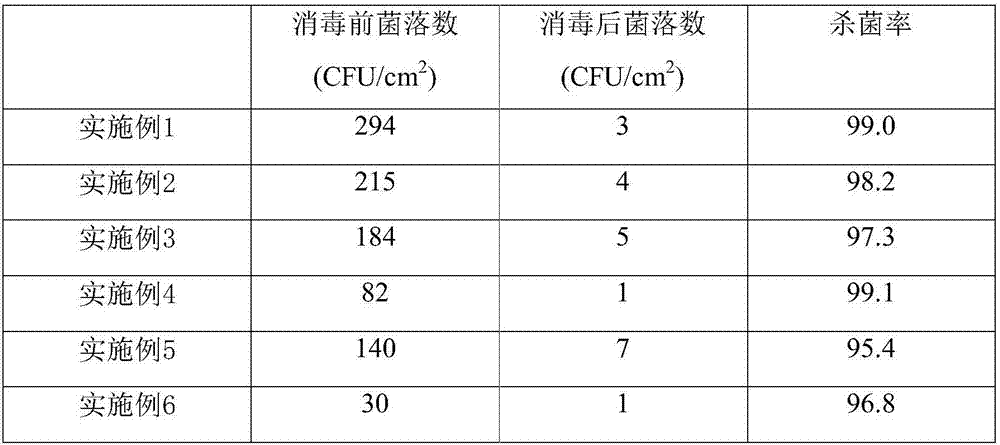

Examples

Embodiment 1

[0029] (1) Dissolve 2.5g of tea tree essential oil and 15g of lanolin in 90g of glycerol, add 10g of squalane, 10g of trehalose and 5g of stearic acid, heat and stir at 90°C;

[0030] (2) Add 55 g of sodium lauroyl sarcosinate and 50 g of coconut oil fatty acid monoethanolamide respectively in 200 g of deionized water, and stir evenly;

[0031] (3) Place the product obtained in steps (1) and (2) in a homogeneous dispersing emulsifier, set the shear force at 600 rpm, heat up to 80°C, and stir at a constant temperature for 35 minutes;

[0032] (4) Add 45g of sodium chloride, lower the temperature to 45°C, set the shear force to 1000rpm, and stir for 30 minutes to fully dissolve the sodium chloride under the strong shear force and achieve emulsification and homogeneity;

[0033] (5) Add 10 g of iodopropynyl butyl carbamate and 7 g of pearl paste, the temperature and shear force are constant, and the stirring time is 25 min;

[0034] (6) Add 1g of essence, reduce the shear force ...

Embodiment 2

[0038] (1) Dissolve 5 g of cinnamon essential oil and 18 g of lanolin in 85 g of propylene glycol, add 15 g of jojoba oil, 15 g of sodium alginate, and 8 g of stearic acid, heat and stir at 80°C;

[0039] (2) Add fatty alcohol polyoxyethylene ether sodium sulfate 65g and coconut oil fatty acid diethanolamide 50g respectively in 200g deionized water, and stir evenly;

[0040] (3) Place the product obtained in steps (1) and (2) in a homogeneous dispersing emulsifier, set the shear force at 900 rpm, raise the temperature to 70°C, and stir at a constant temperature for 35 minutes;

[0041] (4) Add 40g of sodium chloride, cool down to 45°C, set the shear force to 1000rpm, and stir for 30min to fully dissolve the sodium chloride under the action of strong shear force and achieve emulsification and homogeneity;

[0042] (5) Add 4 g of triclosan and 10 g of pearl paste, keep the temperature and shear force unchanged, and stir for 25 minutes;

[0043] (6) Add 1g of essence, reduce the...

Embodiment 3

[0047] (1) Dissolve 10g of geranium essential oil and 30g of lanolin with 100g of sorbitol, add 15g of isooctyl palmitate, 12g of saffron sugar, and 2g of stearic acid, heat and stir at 60°C;

[0048] (2) Add 85 g of sodium lauryl sulfate and 45 g of alkyl glucoside respectively in 160 g of deionized water, and stir evenly;

[0049] (3) Place the product obtained in steps (1) and (2) in a homogeneous dispersing emulsifier, set the shear force at 1200 rpm, heat up to 60°C, and stir at a constant temperature for 35 minutes;

[0050] (4) Add 25g of sodium chloride, lower the temperature to 45°C, set the shear force to 500rpm, and stir for 60 minutes to fully dissolve the sodium chloride under the action of strong shear force and achieve emulsification and homogeneity;

[0051] (5) Add 20 g of chlorhexidine acetate and 20 g of pearlescent slurry, keep the temperature and shear force unchanged, and stir for 30 minutes;

[0052] (6) Add 1g of essence, reduce the shear force to 800r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com