A kind of melamine drying brightener and preparation method thereof

A brightener and drying technology, applied in the direction of drying agent, chemical instrument and method, detergent composition, etc., can solve the problems of slow drying speed and large marks of melamine tableware, and achieve rapid drying and leaving Less scars and stable product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

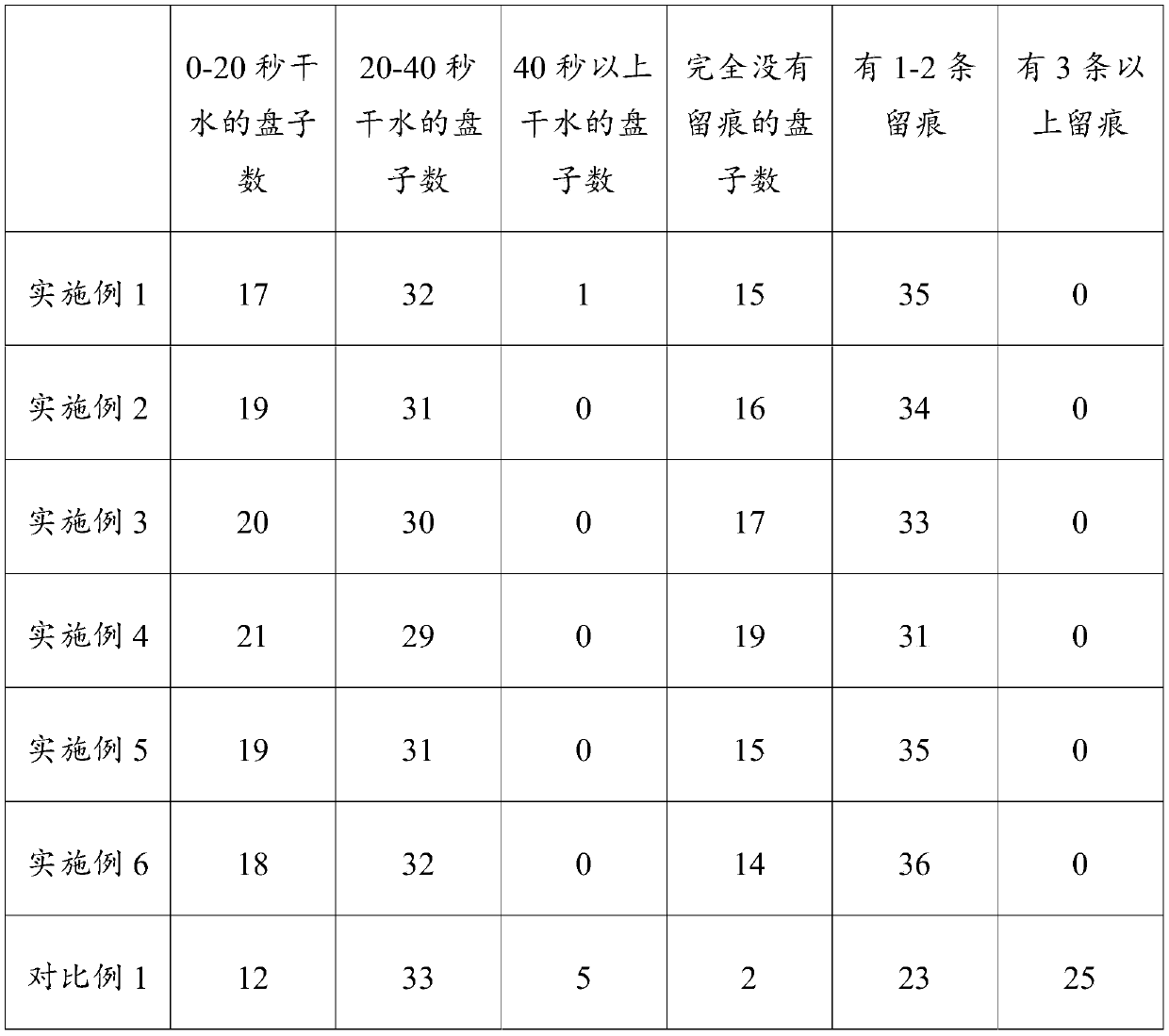

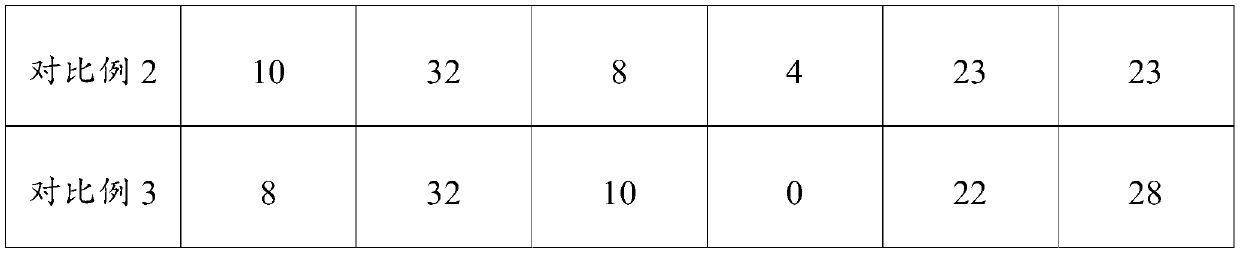

Examples

preparation example Construction

[0028] Also provided is the preparation method of the drying brightener, comprising the following steps:

[0029] 1) Add deionized water into the batching pot, and add isothiazolinone at the same time.

[0030] 2) Add citric acid and stir until dissolved.

[0031] 3) Add component A, stir until dissolved, and the solution becomes milky white at this time.

[0032] 4) Add component B, stir until dissolved, and the solution turns from milky white to translucent.

[0033] 5) Add sodium polyacrylate and stir until dissolved.

[0034] 6) Add isopropanol, stir until dissolved, and the final solution is a stable translucent color.

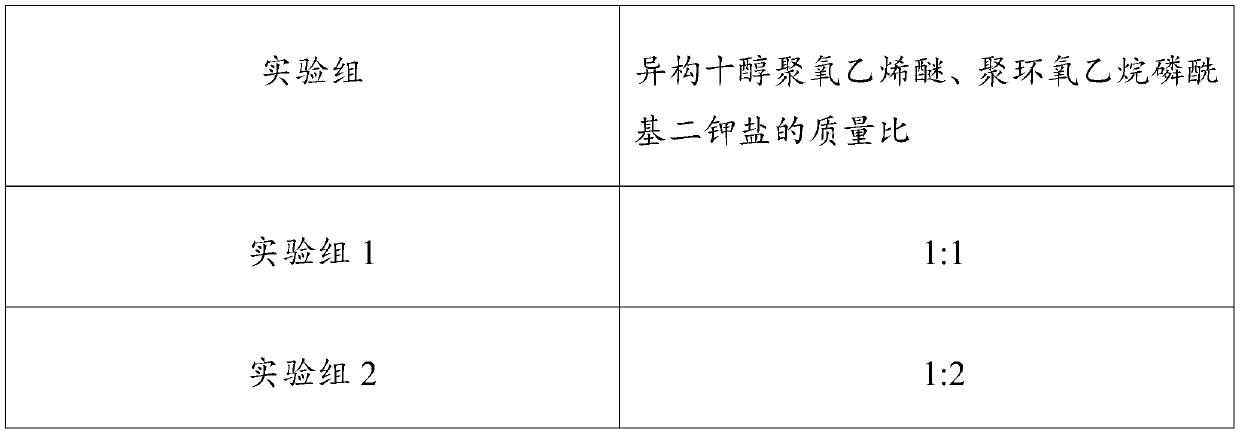

[0035] In the present invention, isomeric decanol polyoxyethylene ether (component A) and polyethylene oxide phosphoryl dipotassium salt (component B) should be added in sequence, and component B should be added after component A is fully dissolved and dispersed , the two cannot be added at the same time, if added at the same time, the transparency of...

Embodiment 1

[0037] The drying brightener of this embodiment includes the following components in mass percentage, 2% of isomeric decanol polyoxyethylene ether, 2% of polyethylene oxide phosphoryl dipotassium salt, 1.5% of sodium polyacrylate, and 1% of isopropanol. %, 1% citric acid, 0.1% isothiazolinone, and the balance of water. The preparation method of this embodiment is as above.

Embodiment 2

[0039] The drying brightener of this embodiment includes the following components in mass percentage, 3.5% of isomeric decanol polyoxyethylene ether, 4% of polyethylene oxide phosphoryl dipotassium salt, 1% of sodium polyacrylate, and 2% of isopropanol. %, 2% citric acid, 0.2% isothiazolinone, and the balance of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com