Production process and production system of high barrier paper for cigarettes

A production process, high barrier technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

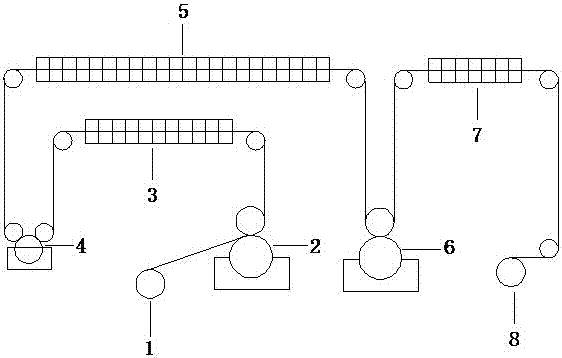

Image

Examples

Embodiment 1

[0023] Configure water-based moisture retention paint:

[0024] (1) Preparation of partially hydrolyzed ethylene-vinyl acetate copolymer: Vinyl acetate and ethylene monomers are used as basic raw materials, among which 70g of vinyl acetate and 30g of ethylene are copolymerized by emulsion polymerization to obtain ethylene-vinyl acetate copolymers 100g of the emulsion, and then partially hydrolyzed under the action of 15% NaOH to obtain 100g of partially hydrolyzed ethylene-vinyl acetate copolymer with a degree of hydrolysis of 35%;

[0025] (2) Mix 20g of waterborne acrylic copolymer with a weight ratio of methyl methacrylate-ethyl acrylate-butyl acrylate copolymer: polyacrylic acid=1:1, 20g polyvinyl acetate and 50g water to obtain Mixed emulsion

[0026] (3) Stir the partially hydrolyzed ethylene-vinyl acetate copolymer and add the mixed emulsion. After stirring evenly, add 4g of Foamex902 antifoaming agent and 2.5g of O2C preservative and continue to stir for 25min to obtain a wa...

Embodiment 2

[0033] Configure water-based moisture retention paint:

[0034] (1) Preparation of partially hydrolyzed ethylene-vinyl acetate copolymer: Vinyl acetate and ethylene monomers are used as basic raw materials, of which 48g vinyl acetate and 32g ethylene are copolymerized by emulsion polymerization to obtain ethylene-vinyl acetate copolymers 80g of the product emulsion, then partially hydrolyzed under the action of 15% NaOH to obtain 80g of a partially hydrolyzed ethylene-vinyl acetate copolymer with a degree of hydrolysis of 65%;

[0035] (2) Mix the weight ratio of methyl methacrylate-butyl acrylate-acrylic acid copolymer: polymethyl methacrylate=5:2 waterborne acrylic copolymer 35g, polyvinyl acetate 35g and water 45g. Uniformly obtain a mixed emulsion;

[0036] (3) Stir the partially hydrolyzed ethylene-vinyl acetate copolymer and add the mixed emulsion. After stirring evenly, add 4 g of Foamex902 defoamer and 2.5 g of O2C preservative and continue stirring for 35 minutes to obtain ...

Embodiment 3

[0043] Configure water-based moisture retention paint:

[0044] (1) Preparation of partially hydrolyzed ethylene-vinyl acetate copolymer: vinyl acetate and ethylene monomer are used as basic raw materials, among which 20g of vinyl acetate and 20g of ethylene are copolymerized by emulsion polymerization to obtain ethylene-vinyl acetate copolymer 40g of the emulsion, and then partially hydrolyzed under the action of 15% NaOH to obtain 40g of partially hydrolyzed ethylene-vinyl acetate copolymer with a degree of hydrolysis of 80%;

[0045] (2) Mix 50 g of methyl methacrylate-butyl acrylate-acrylic acid copolymer, 45 g of polyvinyl acetate and 55 g of water to obtain a mixed emulsion;

[0046] (3) Stir the partially hydrolyzed ethylene-vinyl acetate copolymer and add the mixed emulsion. After stirring evenly, add 4g of Foamex902 defoamer and 2.5g of O2C preservative and continue stirring for 30 minutes to obtain a water-based moisture retention coating.

[0047] Configure water-based acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com