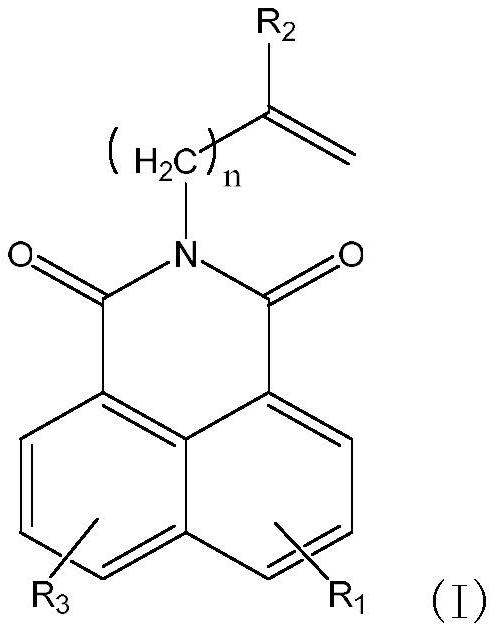

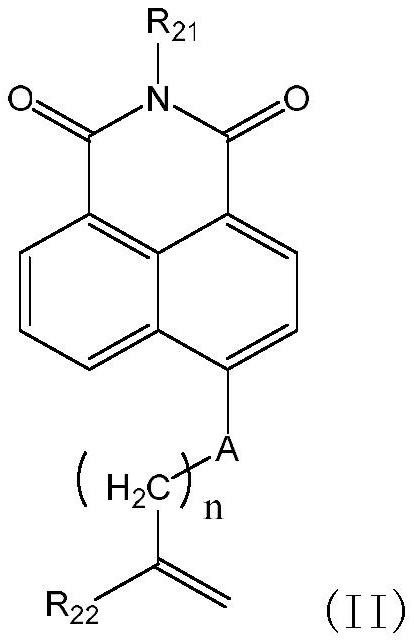

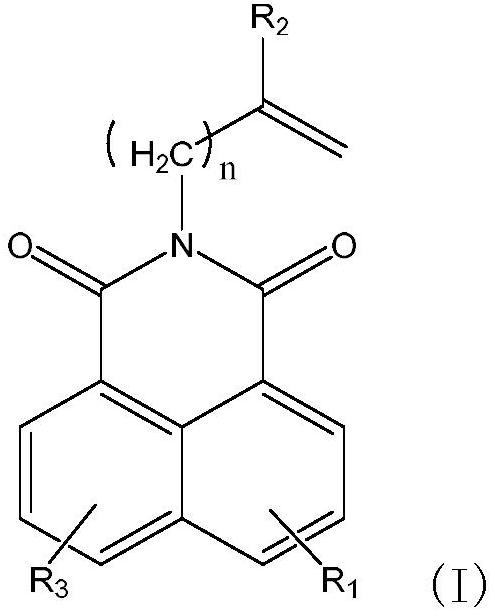

Fluorescent naphthalimide polymers and solutions thereof for water system fouling control

A fluorescent polymer, polymer technology, used in fluorescence/phosphorescence, luminescent materials, scale removal and water softening, etc., can solve problems such as inability to maintain free chlorine, low solubility, and damage to fluorescent signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0460] Polymer Example 1: Synthesis of N-allyl Naphthalimide Polymer

[0461] 190.1 g of deionized water was initially added to a 1 liter glass reactor (equipped with a stirrer inlet, water cooled condenser, thermocouple and adapters (for addition of monomer and initiator solutions)). The reactor contents were heated to 95°C. By dissolving 298.4g acrylic acid (4.14mol, 94.5mol% polymer) in 23.1g DMF, 2.59g N-allyl naphthalimide (monomer embodiment 1, molecular weight 237, 0.0109mol, 0.25mol% polymerization The mixed monomer solution composed of the substance) is mixed, and then sent into the reactor according to the measured slow addition amount, and stirred for more than 4 hours. Simultaneously, a solution of 24.1 g of sodium hypophosphite monohydrate (0.23 mol, 5.28 mol% polymer) dissolved in 72 g of water was injected into the reactor for more than 4 hours, starting at the same time as the monomer solution. Simultaneously, an initiator solution of 6.68 g of sodium persulf...

Embodiment 2

[0462] Polymer Example 2: Synthesis of N-allyl Naphthalimide Polymer

[0463]190.3 g of deionized water was first added to a 1 liter glass reactor (equipped with stirrer inlet, water cooled condenser, thermocouple and adapters (for addition of monomer and initiator solutions)). The reactor contents were heated to 95°C. By dissolving in 46.6g DMF 298.4g acrylic acid (4.14mol, 94.23mol% polymer), 5.18g N-allyl naphthalimide (monomer embodiment 1, molecular weight 237, 0.0218mol, 0.5mol% polymerization The mixed monomer solution composed of the substance) is mixed, and then sent into the reactor according to the measured slow addition amount, and stirred for more than 4 hours. 24.1 g of sodium hypophosphite monohydrate (0.23 mol, 5.27 mol% polymer) dissolved in 72 g of water was simultaneously injected into the reactor over 4 hours, starting at the same time as the monomer solution. Simultaneously, an initiator solution of 6.68 g of sodium persulfate dissolved in 68.4 g of wate...

Embodiment 3

[0464] Embodiment 3: Fluorescent signal intensity

[0465] The polymer samples of Polymer Examples 1 and 2 were each diluted to 10 ppm in water, and the fluorescence signal was determined by exciting the samples at the excitation wavelength and measuring at the emission wavelength described in Table 1.

[0466] Table 1: Fluorescence data of polymers

[0467]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com